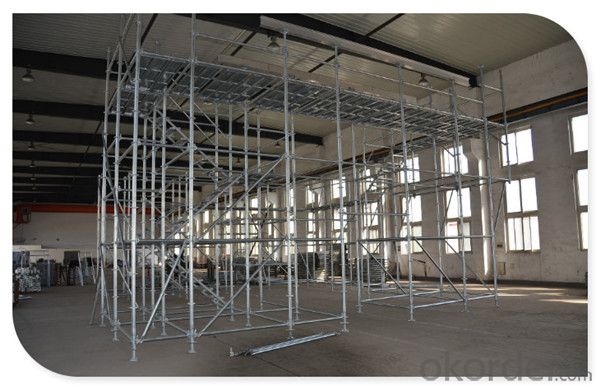

En12810 Construction Tower Ringlock Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of En12810 Construction Tower Ringlock Scaffolding System

Type:

Material:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Surface Treatment:

Certificate:

Color:

Production Capability:

Delivery Time:

Export Markets:

Descriptions of En12810 Construction Tower Ringlock Scaffolding System

1. Standard:

3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

2. Ledger:

3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

3. Diagonal brace:

3000x2000mm, 1780x2000mm, 1000x1500mm, 1000x2000mm, 1500x2000mm.

4. Tube specification:

Φ 48.3x4.0mm, φ 48.0 x3.25mm, φ 48.0 x3.0mm.

5. Surface Finish:

Hot DIP Galv. Electric Galv.Powder coating, Dip Painting.

6. Material:

Q235, Q345

7. Certificate:

EN12810,SGS test report for loading capacity.

The Parts of En12810 Construction Platform Ringlock Scaffolding

| DESCRIPTION | MATERIAL | QTY. (PCS) | W. T. (KG/PC) | SURFACE |

| 3.00m standard | Q345 48.3*3.2mm | 1.00 | 15.3 | Hot-dipped Galvanized |

| 2.50m standard | Q345 48.3*3.2mm | 1.00 | 12.9 | Hot-dipped Galvanized |

| 2.00m standard | Q345 48.3*3.2mm | 1.00 | 10.5 | Hot-dipped Galvanized |

| 1.50m standard | Q345 48.3*3.2mm | 1.00 | 8.1 | Hot-dipped Galvanized |

| 1.00m standard | Q345 48.3*3.2mm | 1.00 | 5.7 | Hot-dipped Galvanized |

| 0.50m standard | Q345 48.3*3.2mm | 1.00 | 3.3 | Hot-dipped Galvanized |

| 2.00m ledger | Q345 48.3*2.5mm | 1.00 | 6.8 | Hot-dipped Galvanized |

| 1.80m ledger | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 1.50m ledger | Q345 48.3*2.5mm | 1.00 | 5.3 | Hot-dipped Galvanized |

| 1.20m ledger | Q345 48.3*2.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.90m ledger | Q345 48.3*2.5mm | 1.00 | 3.5 | Hot-dipped Galvanized |

| 0.60m ledger | Q345 48.3*2.5mm | 1.00 | 2.6 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q235 33.5*2.3mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.7 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.4 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.1 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6.3 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.7 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.8 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.4 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.90*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.1 | Hot-dipped Galvanized |

| 0.60*1.00m brace | Q235 33.5*2.3mm | 1.00 | 3.8 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q345 48.3*2.5mm | 1.00 | 10.2 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.8 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.2 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q345 48.3*2.5mm | 1.00 | 8.8 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q345 48.3*2.5mm | 1.00 | 9.1 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8.7 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7.4 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q345 48.3*2.5mm | 1.00 | 6.6 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q345 48.3*2.5mm | 1.00 | 8.3 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7.7 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 0.9*1m brace | Q345 48.3*2.5mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 0.6*1m brace | Q345 48.3*2.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.88m board bracket | Q345 48.3*2.5mm | 1.00 | 9.5 | Hot-dipped Galvanized |

| 0.60m base collar down | Q235 38.1*4.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.60m base collar up | Q235 38.1*4.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.24*2.00m Plank | DX51D-Z80 | 1.00 | 8.2 | Hot-dipped Galvanized |

| 0.24*1.80m Plank | DX51D-Z80 | 1.00 | 7.5 | Hot-dipped Galvanized |

| 0.24*1.50m Plank | DX51D-Z80 | 1.00 | 6.5 | Hot-dipped Galvanized |

| 0.24*1.20m Plank | DX51D-Z80 | 1.00 | 5.5 | Hot-dipped Galvanized |

| 0.24*0.90m Plank | DX51D-Z80 | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.50*2.00m Plank | DX51D-Z80 | 1.00 | 15.3 | Hot-dipped Galvanized |

| 0.50*1.80m Plank | DX51D-Z80 | 1.00 | 14 | Hot-dipped Galvanized |

| 0.50*1.50m Plank | DX51D-Z80 | 1.00 | 11.9 | Hot-dipped Galvanized |

| 0.50*1.20m Plank | DX51D-Z80 | 1.00 | 9.9 | Hot-dipped Galvanized |

| 0.50*0.90m Plank | DX51D-Z80 | 1.00 | 7.9 | Hot-dipped Galvanized |

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: What are the requirements for the construction of the scaffold eye in the building?

- SelectionThe project uses 48 mm, 3.5mm wall thickness steel pipe and the corresponding fasteners, dense mesh safety net, big eyes, etc.. Among them, the specification of the steel pipe is from 0.5m to 6m, and the fastener mainly has a rotating shaft, a cross and a joint fastener. Bowl buckle scaffold also uses Phi 48, 3.5 wall thickness of steel pipe and the corresponding fasteners, mainly with 1 x 1.0m, 1.2 x 1.2m, 1.5 x 1.5m and other specifications. Foot board mainly 2M and 3M two.

- Q: What are the components of a mobile scaffolding

- The utility model relates to a standard steel pipe scaffold which is connected with the main structure of the wall and is connected with the main structure of the building.

- Q: Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q: Fastener type steel pipe scaffold composed of components

- Fastener type steel pipe scaffold components are mainly shelf

- Q: What are the main safety problems when dismantling the scaffold

- 5, all construction materials must be set according to the material classification management requirements must be neatly stacked, "work finished, as material, the site is clean before work".6, on-site construction waste in a timely manner to clean up and deal with the designated place.7, scaffolding workers must be trained and qualified, safety examination, hold certificate to posts jiazigong.

- Q: THIS METAL SCAFFOLDING IS CONNECTED TO EARTH.Need 2 more questions to be answered:1.Is he going to be electrocuted if he wasn't holding the metal scaffolding?2.will the current flow through him or through the wire in both cases?

- I'll assume you mean a LIVE wire, AC. 1. If there is no connection to ground at all, NO. Birds can sit on live wires. 2. The current will flow from wire through body and scaffold to ground, then from ground through scaffold and body to wire, reversing at a rate of 60 times per second (America). Depending on the voltage on the wire, that person will most likely die or even be burned apart.

- Q: I know people have different pain thresholds. But I was wondering if it was more painful than a lobe piercing? It will be done with a needle and are they aloud to freeze it? Or is it not needed?

- Scaffold/Industrial piercings definately hurt more than a regular lobe piercings because it's in the cartilage area and its pierced at a larger gauge but the pain is bareable. On a scale of 1 to 10 (10 being the worst pain) I would say an Industrial would be anywhere from a 4-6 depending on your pain threshold. Freezing it probably wouldn't be nessesssary. I got a 14g Industrial pierced on one ear and a 16g helix on the other both on the same day (the industrial was done first) and in my opinion the 16g helix hurt more. So it really depends on how well you tolerate pain

- Q: what happened when author dimmesdale went to the scaffolding in town square?

- Which time? The first time he went there at night, admits his sin, mets up with Hester Prynne and Pearl, and an A appears in the sky. The second time, Arthur Dimmesdale reveals this secret to the public. He then has a heart attack on the scaffold and dies.

- Q: Standard Specification for bowl buckle scaffold

- The utility model has the advantages of reasonable structure, simple manufacturing process, easy operation and wide application range, and can fully meet the construction requirements of buildings, bridges and culverts, tunnels, chimneys, water towers and other buildings

- Q: What are the safety requirements for the dismantling of construction scaffolding

- (1) prior to the dismantling of the scaffold, the work instructions for the removal shall be prepared and submitted for approval according to the design approval procedure of the scaffold. No work instructions or safety measures are not implemented, it is strictly prohibited to dismantle the work.(2) prior to the removal of the work, the approved work instructions and construction plans shall be made to the site construction personnel. And should check the implementation of site safety measures.

Send your message to us

En12810 Construction Tower Ringlock Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords