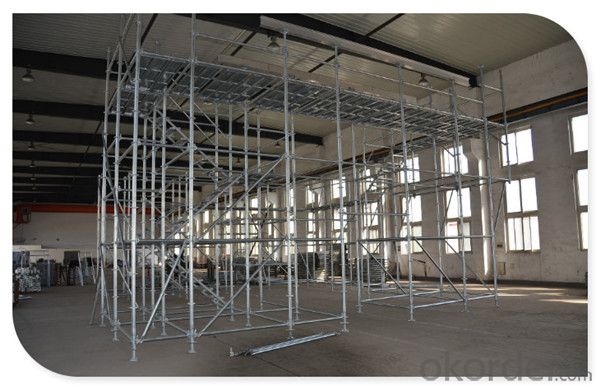

En12810 Construction Platform Steel Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of En12810 Construction Platform Steel Scaffolding System

Type:

Material:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Surface Treatment:

Certificate:

Color:

Production Capability:

Delivery Time:

Export Markets:

Descriptions of En12810 Construction Platform Steel Scaffolding System

1. Standard:

3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

2. Ledger:

3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

3. Diagonal brace:

3000x2000mm, 1780x2000mm, 1000x1500mm, 1000x2000mm, 1500x2000mm.

4. Tube specification:

Φ 48.3x4.0mm, φ 48.0 x3.25mm, φ 48.0 x3.0mm.

5. Surface Finish:

Hot DIP Galv. Electric Galv.Powder coating, Dip Painting.

6. Material:

Q235, Q345

7. Certificate:

EN12810,SGS test report for loading capacity.

The Parts of En12810 Construction Platform Steel Scaffolding System

| DESCRIPTION | MATERIAL | QTY. (PCS) | W. T. (KG/PC) | SURFACE |

| 3.00m standard | Q345 48.3*3.2mm | 1.00 | 15.3 | Hot-dipped Galvanized |

| 2.50m standard | Q345 48.3*3.2mm | 1.00 | 12.9 | Hot-dipped Galvanized |

| 2.00m standard | Q345 48.3*3.2mm | 1.00 | 10.5 | Hot-dipped Galvanized |

| 1.50m standard | Q345 48.3*3.2mm | 1.00 | 8.1 | Hot-dipped Galvanized |

| 1.00m standard | Q345 48.3*3.2mm | 1.00 | 5.7 | Hot-dipped Galvanized |

| 0.50m standard | Q345 48.3*3.2mm | 1.00 | 3.3 | Hot-dipped Galvanized |

| 2.00m ledger | Q345 48.3*2.5mm | 1.00 | 6.8 | Hot-dipped Galvanized |

| 1.80m ledger | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 1.50m ledger | Q345 48.3*2.5mm | 1.00 | 5.3 | Hot-dipped Galvanized |

| 1.20m ledger | Q345 48.3*2.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.90m ledger | Q345 48.3*2.5mm | 1.00 | 3.5 | Hot-dipped Galvanized |

| 0.60m ledger | Q345 48.3*2.5mm | 1.00 | 2.6 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q235 33.5*2.3mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.7 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.4 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.1 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6.3 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.7 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.8 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.4 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.90*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.1 | Hot-dipped Galvanized |

| 0.60*1.00m brace | Q235 33.5*2.3mm | 1.00 | 3.8 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q345 48.3*2.5mm | 1.00 | 10.2 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.8 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.2 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q345 48.3*2.5mm | 1.00 | 8.8 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q345 48.3*2.5mm | 1.00 | 9.1 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8.7 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7.4 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q345 48.3*2.5mm | 1.00 | 6.6 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q345 48.3*2.5mm | 1.00 | 8.3 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7.7 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 0.9*1m brace | Q345 48.3*2.5mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 0.6*1m brace | Q345 48.3*2.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.88m board bracket | Q345 48.3*2.5mm | 1.00 | 9.5 | Hot-dipped Galvanized |

| 0.60m base collar down | Q235 38.1*4.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.60m base collar up | Q235 38.1*4.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.24*2.00m Plank | DX51D-Z80 | 1.00 | 8.2 | Hot-dipped Galvanized |

| 0.24*1.80m Plank | DX51D-Z80 | 1.00 | 7.5 | Hot-dipped Galvanized |

| 0.24*1.50m Plank | DX51D-Z80 | 1.00 | 6.5 | Hot-dipped Galvanized |

| 0.24*1.20m Plank | DX51D-Z80 | 1.00 | 5.5 | Hot-dipped Galvanized |

| 0.24*0.90m Plank | DX51D-Z80 | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.50*2.00m Plank | DX51D-Z80 | 1.00 | 15.3 | Hot-dipped Galvanized |

| 0.50*1.80m Plank | DX51D-Z80 | 1.00 | 14 | Hot-dipped Galvanized |

| 0.50*1.50m Plank | DX51D-Z80 | 1.00 | 11.9 | Hot-dipped Galvanized |

| 0.50*1.20m Plank | DX51D-Z80 | 1.00 | 9.9 | Hot-dipped Galvanized |

| 0.50*0.90m Plank | DX51D-Z80 | 1.00 | 7.9 | Hot-dipped Galvanized |

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Scaffolding installation and precautions?

- The backing plate and the base should be placed on the positioning line accurately.2, when the erection of the column, the outer diameter of the steel pipe is strictly prohibited, the adjacent column of the docking fasteners shall not be in the same height, staggered distance should meet the structural requirements.

- Q: i already found the force in rope 2 but im not getting the force in rope 1.

- The tension in the two vertical ropes must sum to 700N in order to balance the window washer. EDIT. In order to find the answer for each rope, I need to know how long the scaffold is and where the window washer is standing. EDIT. Taking moments about the end nearest to window washer. T1*3.044 = 298.6*1.522 + 700*1.51 ----> T1 = 496.54 N (2. d. p.) Taking moments about the other end. T2*3.044 = 298.6*1.522 + 700*1.534 ----> T2 = 502.06 N (2. d. p.) T1 + T2 = 496.54 + 502.06 = 998.6 = 700 + 298.6 as required.

- Q: Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q: What does Scaffolding mean in the educational talk?

- It refers to the ways that you break a concept and/or a task down using graphic organizers, etc.

- Q: According to the standard set up double scaffolding scaffolding to the number of meters per square meter

- The span, the rod step is easy to calculate, I have done the program in general 4.4.8 meters

- Q: Can you do the outer scaffolding?

- 6 15cm. When the oblique rod in a span of two step distance, it is appropriate in the intersection of the large cross bar to add a small bar, the oblique abdominal rod fixed on its protruding end. 7, scissors (1) of the scaffold bridging with columns, longitudinal and transverse horizontal rod synchronous erection, with long scissors along the elevated continuous layout

- Q: What are the characteristics of Pankou scaffolding

- Pankou scaffolding, unique technology of hot dip galvanizing, hot-dip galvanizing is a strong adhesion, used for a long time, a uniform film coating.

- Q: I would like to ask how much scaffolding steel prices, scaffolding steel pipe use what are the requirements?

- 10, the scaffolding removed, should first check to connect with the building, and will remain on the scaffold material, clean, and other debris from the top down, according to the first after the demolition, demolition of first order after installation, demolition materials should be passed down or lifted onto the ground, step one clear. Not allowed to use the method of step down, it is strictly prohibited to throw down or push (pull) down the demolition method.11, take off scaffolding, should be set up warning area, and sent a special alert. In case of more than six winds and bad weather, the scaffolding should be stopped.

- Q: What are scaffold spanners used for?

- Ratchet Podger Spanners...Aluminium Scaff Spanners Spanners are wide wrenches that are made from durable metals. Spanners are made specifically for scaffolding and are designed to fit into the tool belt nicely. Spanners are very useful for a number of jobs and are often used along with other scaffold tools on a safety lanyard to prevent dropping the tool to the street below. Spanners work the same as traditional wrenches but like many scaffolding tools are made with a hole in the end of the wrench for the safety strap to be inserted through. Stainless steel and aluminum are the most commonly used metals for spanners to ensure durability even if the item is dropped from high.

- Q: what do you think?pain wise? i know it's going to hurt as it's a peircing (duh) but will it hurt especially as it's two thick pieces of cartilage?

- It's not going to hurt 'especially' don't worry. :) xoxox

Send your message to us

En12810 Construction Platform Steel Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords