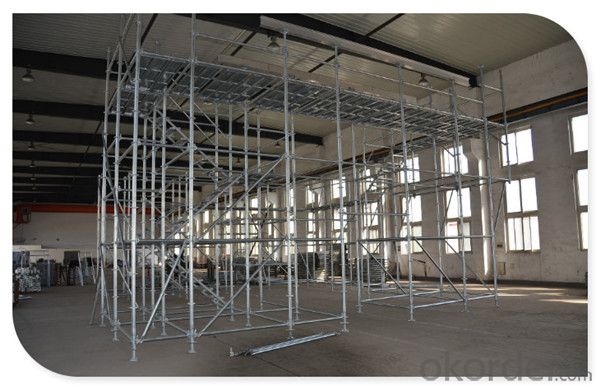

En12810 Construction Platform Ringlock Scaffold System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of En12810 Construction Platform Ringlock Scaffold System

Type:

Material:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Surface Treatment:

Certificate:

Color:

Production Capability:

Delivery Time:

Export Markets:

Descriptions of En12810 Construction Platform Ringlock Scaffold System

1. Standard:

3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

2. Ledger:

3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

3. Diagonal brace:

3000x2000mm, 1780x2000mm, 1000x1500mm, 1000x2000mm, 1500x2000mm.

4. Tube specification:

Φ 48.3x4.0mm, φ 48.0 x3.25mm, φ 48.0 x3.0mm.

5. Surface Finish:

Hot DIP Galv. Electric Galv.Powder coating, Dip Painting.

6. Material:

Q235, Q345

7. Certificate:

EN12810,SGS test report for loading capacity.

The Parts of En12810 Construction Platform Ringlock Scaffold System

| DESCRIPTION | MATERIAL | QTY. (PCS) | W. T. (KG/PC) | SURFACE |

| 3.00m standard | Q345 48.3*3.2mm | 1.00 | 15.3 | Hot-dipped Galvanized |

| 2.50m standard | Q345 48.3*3.2mm | 1.00 | 12.9 | Hot-dipped Galvanized |

| 2.00m standard | Q345 48.3*3.2mm | 1.00 | 10.5 | Hot-dipped Galvanized |

| 1.50m standard | Q345 48.3*3.2mm | 1.00 | 8.1 | Hot-dipped Galvanized |

| 1.00m standard | Q345 48.3*3.2mm | 1.00 | 5.7 | Hot-dipped Galvanized |

| 0.50m standard | Q345 48.3*3.2mm | 1.00 | 3.3 | Hot-dipped Galvanized |

| 2.00m ledger | Q345 48.3*2.5mm | 1.00 | 6.8 | Hot-dipped Galvanized |

| 1.80m ledger | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 1.50m ledger | Q345 48.3*2.5mm | 1.00 | 5.3 | Hot-dipped Galvanized |

| 1.20m ledger | Q345 48.3*2.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.90m ledger | Q345 48.3*2.5mm | 1.00 | 3.5 | Hot-dipped Galvanized |

| 0.60m ledger | Q345 48.3*2.5mm | 1.00 | 2.6 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q235 33.5*2.3mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.7 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.4 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q235 33.5*2.3mm | 1.00 | 6.1 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6.3 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q235 33.5*2.3mm | 1.00 | 6 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q235 33.5*2.3mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q235 33.5*2.3mm | 1.00 | 4.7 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.8 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q235 33.5*2.3mm | 1.00 | 5.4 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.9 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.90*1.00m brace | Q235 33.5*2.3mm | 1.00 | 4.1 | Hot-dipped Galvanized |

| 0.60*1.00m brace | Q235 33.5*2.3mm | 1.00 | 3.8 | Hot-dipped Galvanized |

| 2.00*2.00m brace | Q345 48.3*2.5mm | 1.00 | 10.2 | Hot-dipped Galvanized |

| 1.80*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.8 | Hot-dipped Galvanized |

| 1.50*2.00m brace | Q345 48.3*2.5mm | 1.00 | 9.2 | Hot-dipped Galvanized |

| 1.20*2.00m brace | Q345 48.3*2.5mm | 1.00 | 8.8 | Hot-dipped Galvanized |

| 2.00*1.50m brace | Q345 48.3*2.5mm | 1.00 | 9.1 | Hot-dipped Galvanized |

| 1.80*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8.7 | Hot-dipped Galvanized |

| 1.50*1.50m brace | Q345 48.3*2.5mm | 1.00 | 8 | Hot-dipped Galvanized |

| 1.20*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7.4 | Hot-dipped Galvanized |

| 0.90*1.50m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 0.60*1.50m brace | Q345 48.3*2.5mm | 1.00 | 6.6 | Hot-dipped Galvanized |

| 2.00*1.00m brace | Q345 48.3*2.5mm | 1.00 | 8.3 | Hot-dipped Galvanized |

| 1.80*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7.7 | Hot-dipped Galvanized |

| 1.50*1.00m brace | Q345 48.3*2.5mm | 1.00 | 7 | Hot-dipped Galvanized |

| 1.20*1.00m brace | Q345 48.3*2.5mm | 1.00 | 6.2 | Hot-dipped Galvanized |

| 0.9*1m brace | Q345 48.3*2.5mm | 1.00 | 5.6 | Hot-dipped Galvanized |

| 0.6*1m brace | Q345 48.3*2.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.88m board bracket | Q345 48.3*2.5mm | 1.00 | 9.5 | Hot-dipped Galvanized |

| 0.60m base collar down | Q235 38.1*4.5mm | 1.00 | 4.4 | Hot-dipped Galvanized |

| 0.60m base collar up | Q235 38.1*4.5mm | 1.00 | 5.2 | Hot-dipped Galvanized |

| 0.24*2.00m Plank | DX51D-Z80 | 1.00 | 8.2 | Hot-dipped Galvanized |

| 0.24*1.80m Plank | DX51D-Z80 | 1.00 | 7.5 | Hot-dipped Galvanized |

| 0.24*1.50m Plank | DX51D-Z80 | 1.00 | 6.5 | Hot-dipped Galvanized |

| 0.24*1.20m Plank | DX51D-Z80 | 1.00 | 5.5 | Hot-dipped Galvanized |

| 0.24*0.90m Plank | DX51D-Z80 | 1.00 | 4.5 | Hot-dipped Galvanized |

| 0.50*2.00m Plank | DX51D-Z80 | 1.00 | 15.3 | Hot-dipped Galvanized |

| 0.50*1.80m Plank | DX51D-Z80 | 1.00 | 14 | Hot-dipped Galvanized |

| 0.50*1.50m Plank | DX51D-Z80 | 1.00 | 11.9 | Hot-dipped Galvanized |

| 0.50*1.20m Plank | DX51D-Z80 | 1.00 | 9.9 | Hot-dipped Galvanized |

| 0.50*0.90m Plank | DX51D-Z80 | 1.00 | 7.9 | Hot-dipped Galvanized |

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: looking for a scaffolding job in dubai can anyone help?

- Hi okorder , we are Dubai based scaffolding contractor.

- Q: i have now got lumps on my scaffolding and i have searched and it seems to be normal.. i just want to know how to get rid? any ideas? :)

- It recommends tea tree oil, or vitamin E oil applied directly to the area.

- Q: The role of the external scaffolding and the relevant provisions?

- Scaffolding outside the building in the construction of the building is an indispensable important tool for erection. Its role: first, can make the construction personnel in different parts of the operation of the high; two is to ensure the safety of construction personnel in the high altitude operation

- Q: Which God can tell me what is required, how to get ah?

- The same height of the building to be calculated separately, and ultimately is to pay attention to security, you can look at the yuan Tuo mall information on this aspect is still a lot of

- Q: i just need to know the age limit with parental permission?

- I'm pretty sure it's 16-17 with parental permission. I suggest looking up some of the shops in your area and seeing what they say. There usually isn't a set rule for it, every shop is different. Like some shops may refuse seeing, say, a 14 year old, whereas another shop might do it with the parent's permission. Then of course, once you hit 18, you can do whatever you want, lol.

- Q: I plan to have a scaffolding or industrial piercing soon, but don't know where to go.Any suggestions and could you include the prices?x

- Cost depends on the studio. It ranges from 20 to 45 pounds for each piercing, most common price is 25 pounds for each piercing, high quality titanium or stainless steel jewelry included. The industrial is 2 piercings in one so : 25 + 25 = 50 pounds, jewelry included.

- Q: I had my scaffold done on friday, and it's still very sore and swollen. My boyfriend's accidentally caught it a couple of times but not badly and i was wondering if the pain and swelling is normal and if there's anything i can do for it. I've been cleaning it with savlon and have been careful with it x

- u shud check f its swollen and if there is more painin go to the doctors

- Q: along with this question, -what does she think about during this time period?-how does she apprear on the scaffold? -who does she see and how does she feel?THANKS!!=]

- Read the book and find out! I think she's up on the scaffold sometime in spring, but as I said, READ it and make sure.

- Q: Who knows how much the amount of the main material used to take one square metre of conventional double row scaffolding (within 12 meters). For example, how many kilograms of steel pipe, the number of fasteners. The content of the quota is low, I am also very confused, to the completion of the work of the scaffolding rental fees. Very urgent, I hope to know the user to answer. Accident report

- The following is a quote fragment: who knows how to use a square meter of the main raw material of double row scaffolding

- Q: i am getting my industrial (scaffold) pierced on one ear and i want my cartilage on the other ear, how long do i have to wait between them? What are pros and cons for industrial (scaffold)? what are risks and stuff and how much is it? i want to get it so any information or anything i should know would be great thanks especially for industrial:)

- i heard from people after a year an industrial still hurts and they usually have to take them out

Send your message to us

En12810 Construction Platform Ringlock Scaffold System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords