Aluminum A Coil - EN AW-1070 CC Aluminium Coil for Remelting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 1070 CC Aluminium Coil for Remelting Description

EN AW - 1070 CC Aluminium Coil for Remelting is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1070 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 1070 CC Aluminium Coil for Remelting

EN AW - 1070 CC Aluminium Coil for Remelting | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 1070 CC Aluminium Coil for Remelting

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 1070 CC Aluminium Coil for Remelting

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 1070 CC Aluminium Coil for Remelting

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

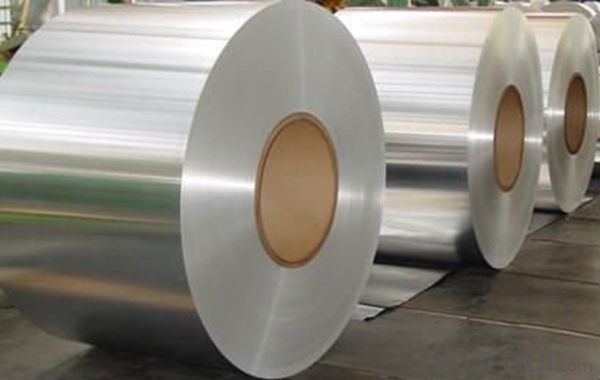

6. Image of EN AW - 1070 CC Aluminium Coil for Remelting

7. Package and shipping of EN AW - 1070 CC Aluminium Coil for Remelting

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the common surface cleaning methods for aluminum coils?

- There are several common surface cleaning methods for aluminum coils that are effective in removing dirt, debris, and other contaminants. One of the most commonly used methods is pressure washing. This involves using a high-pressure water spray to dislodge and remove any dirt or grime from the surface of the coils. Pressure washing can be done using specialized equipment or even a regular garden hose with a spray nozzle attachment. Chemical cleaning is another popular method for cleaning aluminum coils. This method involves using specific cleaning agents or solvents that are designed to break down and remove dirt and contaminants from the surface of the coils. These chemicals are typically applied using a spray bottle or a pump sprayer, and then rinsed off with water after a designated amount of time. Another effective method for cleaning aluminum coils is the use of steam cleaning. This involves using high-temperature steam to loosen and remove dirt and grime from the surface of the coils. Steam cleaning is often used in conjunction with a cleaning agent or solvent to enhance its effectiveness. In addition to these methods, there are also specialized coil cleaning brushes or fin combs that can be used to physically remove any debris or build-up from the coil surfaces. These tools are particularly useful for removing smaller particles or debris that may be trapped in between the fins of the coils. It is important to note that when cleaning aluminum coils, it is crucial to follow the manufacturer's recommendations and guidelines to ensure that the cleaning process is done safely and effectively. Additionally, regular cleaning and maintenance of aluminum coils can help prolong their lifespan and maintain their efficiency.

- Q: I want to remove melted aluminium piston material from an engine cylinder with burning a hole in the cylinder!

- I am quite sure any acid strong enough to dissolve aluminium would be able to dissolve iron and steel, as acid + metal equations can be substituted with any metal and any acid.

- Q: Can aluminum coils be used in the production of window frames?

- Yes, aluminum coils can be used in the production of window frames. Aluminum is a lightweight and durable material that is commonly used in the construction industry due to its corrosion resistance and strength. Aluminum coils can be easily formed into various shapes, including window frames, making them an ideal choice for window manufacturing. Additionally, aluminum is a sustainable material that can be easily recycled, making it an environmentally friendly option for window frame production.

- Q: Can aluminum coils be used for architectural facades?

- Indeed, architectural facades can make use of aluminum coils. The lightweight, durable, and versatile nature of aluminum makes it a favored option for such purposes. With the ability to mold aluminum coils into diverse shapes and sizes, one can create unique and visually pleasing facades. Furthermore, aluminum demonstrates resistance to corrosion, rendering it suitable for outdoor use. Moreover, aluminum allows for easy coating or finishing, enabling an improved aesthetic appeal and protection against environmental factors. All in all, aluminum coils offer an economically viable and environmentally friendly alternative for architectural facades.

- Q: I can't figure out what the metabolic role of aluminum is. Been searching for a while and can't seem to find anything concrete.If you can, please include sources. Thanks!

- I okorder /

- Q: What is the average lifespan of an aluminum coil?

- The average lifespan of an aluminum coil can vary depending on various factors such as the quality of the aluminum, external factors like exposure to weather conditions or chemicals, and how well it is maintained. However, on average, an aluminum coil can last anywhere from 20 to 30 years.

- Q: What are the dimensions of an aluminum coil?

- The dimensions of an aluminum coil can vary depending on the specific application and manufacturer. However, common dimensions for aluminum coils range from 0.15mm to 8mm in thickness, and from 20mm to 2000mm in width. The length of an aluminum coil can be customized to meet specific requirements.

- Q: Why does it take less energy to get aluminum metal from used cans than to get it directly from the ore?

- in order to extract the raw aluminum, you have to heat everything and melt it first, then remove the stuff that precipitates out as it cools or forms via chemical reaction with catalysts you introduce. With aluminum cans, you don't have to raise the temperature much above the melting point of aluminum, since it's already the substance in the can with the highest melting point. With aluminum ore, there can be anything in the ore with pretty much any melting point. In particular, if the ore contains an alloy of aluminum and a metal with a higher melting point than aluminum, then rest assured, you will have to raise the temperature of the ore above the melting point of aluminum in order to melt that alloy, In any case, because the maximum required temperature of the smelter needed to melt used aluminum cans is necessarily lower than the maximum temperature required to work with the ore, less energy is required to get aluminum from used cans than from ore.

- Q: What are the insulation options available for aluminum coils?

- There are several insulation options available for aluminum coils, depending on the specific requirements and applications. Some common insulation options include: 1. Foam Insulation: Foam insulation is a popular choice for aluminum coils as it provides excellent thermal insulation properties. It is available in various forms, such as rigid foam boards or flexible foam sheets, and can be easily cut and fitted around the coils. 2. Fiberglass Insulation: Fiberglass insulation is another commonly used option for aluminum coil insulation. It consists of thin glass fibers that are woven together to create a blanket-like material. Fiberglass insulation is lightweight, easy to install, and offers good thermal and acoustic insulation. 3. Mineral Wool Insulation: Mineral wool insulation is made from natural or synthetic minerals, such as rock or slag, that are melted and spun into fine fibers. It is known for its excellent fire-resistance properties and provides effective thermal insulation for aluminum coils. 4. Reflective Insulation: Reflective insulation is designed to reflect radiant heat away from the aluminum coils. It typically consists of a layer of aluminum foil laminated to a layer of fiberglass or plastic bubble wrap. Reflective insulation is particularly effective in warmer climates where reducing heat gain is a priority. 5. Vapor Barrier Insulation: Vapor barrier insulation is used to prevent the transfer of moisture through the insulation material. It is often applied as a coating or film over the insulation to create a barrier against water vapor, reducing the risk of condensation buildup on the aluminum coils. It is important to consider factors such as thermal conductivity, fire resistance, moisture resistance, and installation requirements when selecting the appropriate insulation option for aluminum coils. Consulting with a professional or referring to manufacturer guidelines can help in determining the most suitable insulation option for specific coil applications.

- Q: Can aluminum coils be used in signage applications?

- Yes, aluminum coils can be used in signage applications. Aluminum is a popular material for signage due to its durability, lightweight nature, and resistance to corrosion. It can be easily formed into various shapes and sizes, making it suitable for different types of signage, including billboards, nameplates, and outdoor signs. Additionally, aluminum can be painted or laminated to achieve different visual effects and enhance the overall appearance of the signage.

Send your message to us

Aluminum A Coil - EN AW-1070 CC Aluminium Coil for Remelting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords