Edge Banding Machines of Different Kinds,PANEL SAW

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Edge Banding Machines-Panel Saw Description

A panel saw is any type of sawing machine with a sliding table that cuts sheets into sized parts.

A sliding panel saw was invented by Wilhelm Altendorf in 1906 in Germany. Its invention set a new standard in woodworking, with dramatic differences from traditional machines. Up to that time, a conventional table saw had no mechanism for edging. Meaning that for the first and second longitudinal cut on untreated massive wood, the lumber always had to be fed manually through the saw blade. The new system accomplished the task more elegantly by allowing the work piece to be fed through the saw blade while lying on a sliding table. Thus cutting becomes faster, accurate and effortless.

Main Features of Edge Banding Machines-Panel Saw

Panel saws are used by cabinet shops to easily cut panels, profiles, solid-wood, MDF, laminates, plastic sheets and sheets into sizes or cabinet components. They are also used by sign shops to cut sheets of aluminum, plastic and wood for their sign blanks. Some higher end panel saws feature computer controls that move the blade and fence systems to preset values. Other lower end machines offer simplicity and ease of use, including full scale hobbyist level panel saws at a mere fraction of the cost. While the entry level machines are designed for light duty usage, they offer home DIYers a cheap alternative for infrequent cutting when accuracy and clean cuts are not required.

Panel saws can have one main saw blade, or a scoring along with a main saw blade. Scoring is used to create a groove, especially in double side laminate before the main saw rips the piece apart, to avoid chipping. The scoring saw rotates in an opposite direction, as the main saw to avoid chipping.

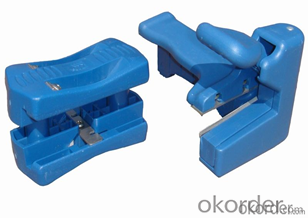

Edge Banding Machines-Panel Saw Images

Edge Banding Machine-Panel Saw Specifications

Maximum cutting length2800mm2800mm

Maximum cutting thickness80mm80mm

Main Blade sizeΦ305×Φ30mmΦ305×Φ30mm

Slot Blade sizeΦ120×Φ22mmΦ120×Φ22mm

Main saw shaft speed4000/5000rpm4000/5000rpm

Slot saw shaft speed9000r/min9000r/min

Main saw motor power5.5kw4kw

Slot saw motor power1.1kw1.1kw

Total power6.6kw5.1kw

Suction mouthΦ100×1Φ100×1

Weight800kg770kg

Box set dimensions3400×1150×1100mm3400×1100×1100mm

FAQ of Edge Banding Machines-Panel Saw

1) What can we do for you?

.We can ensure the quality of the Edge Banding Machines-Panel Saw and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Panel type furniture automatic edge sealing machine. How many grams of hot melt adhesive does it need per meter?

- Generally speaking, the cost of hot melt adhesive for edge banding machine is very small, so few manufacturers will make statistics on it. I checked all the basic data I had about the furniture factory and didn't find it.I asked a friend who was doing hot melt, he said, at about 2 grams. For your reference.

- Q: How much is the banding strip one meter?

- Cabinets used on the edge banding, the price of a few cents a meter, there are also a few dollars a meter. The price is different from its thickness, width, and manufacturer's.. Therefore, suggest that you go directly to the store, or find business advice better.

- Q: How do you calculate the length of an edge strip?

- Generally, a roll is 50 meters or 100 meters.

- Q: Whether or not the upper and lower frames of the solid wood composite door bear edges?

- Solid wood door is characterized by outstanding real word, I suggest you do not edge

- Q: How much is the furniture edge banding machine?

- Enter the Italian woodworking machinery website to see, do the panel furniture equipment, but the products are high-end

- Q: No cutting fault of edge sealing machine

- The rear stroke switch is out of order

- Q: There are two favorite bags are all genuine leatherThe black tape with straps on the shoulder doesn't know how it fell offOne is OK, the other is a bit seriousIt's sticky. It's a little longer on the back of your bag. It'll stick to black sticky glue on your clothesCheck it online and there's no solutionTo the special leather cleaning, cleaning shop also asked them, do not know how to doThe majority of users want to help me,The serious one is hilly's toilet bagWould you like to ask a friend who bought this bag to come across this situation?

- If the black side is not lost if you can buy the special glue leather glue (glue sticky shoes can stick well later), which then coated with a layer of glue, to try if the adhesive is in that will harden the muddy with transparent nail polish can also be replaced, I try also, you can try

- Q: PVC sealing strip extrusion foam what is the reason?

- In addition to some raw materials damp, containing more volatile will cause PVC edge banding in extrusion process will blister, there is a more prone to this phenomenon, namely: lack of thermal stability lead to PVC decomposition bubble. Lack of PVC thermal stability for several reasons: 1. heat stabilizer unqualified or improper selection; 2. heat stabilizer; 3. processing temperature setting is not reasonable, mainly temperature too high; 4. screw extruder of high speed; 5. formula system inside and outside lubrication or collocation unreasonable amount; 6. main raw materials such as stability PVC deficiency. In addition, reasonable mixing processing conditions will greatly reduce the volatile substances in raw materials.

- Q: I want to know how to use the veneer to seal the edges. The bark is 0.6MM. Is it made by hand or by the machine?

- The machine is certainly not much better than manual veneer, stitching in place, not prone to glue glue evenly through the end of the phenomenon

- Q: Solid wood flooring is necessary waterproof paint edge?

- Yes, there is. 1. baseboard - when the floor is installed, there will be 8-12MM gap between the floor and the wall, which is telescopic, and the thickness of the baseboard is designed to cover the gap in the 12-15MM2. be close - this is a polymer or made of wood with a 90 degree angle, length is 2.7 meters, the width of about 2 centimeters or so both sides, glue on the floor covering the gap.It is better to suggest skirting boardsSuggest that you select the Oriental Yuhong productsColor tile sealant (strong weather resistant type)Tile filling agent is made of cement, filler, pigment and modifier. It is applied to the gap between tile and ceramic tile. With ceramic tile, stone and other decorative materials to match, it can provide beautiful finishes, improve the adhesion between the decorative brick and anti-seepage role, but also to alleviate the entire wall or floor covering material internal stress.Wall interface agent (concrete interface agent)Concrete interface agent mainly refers to the application on the concrete surface, by increasing the concrete surface roughness or the strength, significantly improve the bond strength between concrete and other products, which are widely used in all kinds of surface treatment on the cement base.Wall interface agent (concrete interface agent) is a new type of high permeability material composed of polymer emulsion and multifunctional additives. Has good sealing property, strong permeability, surface strength etc., the interface is applicable to concrete and mortar layer.

Send your message to us

Edge Banding Machines of Different Kinds,PANEL SAW

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords