Easy install Fiber cement composite wall panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

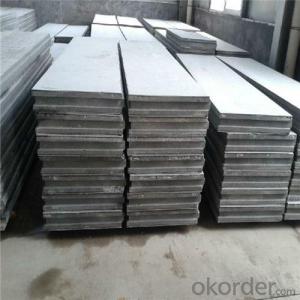

fiber cement sandwich panel

1.Description

4mm fiber cement board as face board;

Cement and EPS beads as core;

Light weight solid composite wall panel;

2.Size

Length: 2270mm, 2440mm, 3000mm

Width: 610mm

Thickness: 50mm, 75mm, 100mm, 120mm, 150mm

3.Performance index

Items | Product size(mm) | |||

50 | 75 | 100 | 120 | |

Anti-impact capacity/times | ≥10 | ≥10 | ≥10 | ≥10 |

Anti-bending damage load/times over deadweight | ≥7 | ≥7 | ≥7 | ≥7 |

Compressive/Mpa | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 |

Softening coefficient/% | ≥1 | ≥1 | ≥1 | ≥1 |

Surface density/kg/m² | ≤50 | ≤75 | ≤90 | ≤100 |

Moisture rate/% | ≤12/10/8 | |||

Drying shrinkage value/mm/m | 0.4 | 0.4 | 0.4 | 0.4 |

Hanging force/N | 1200 | 1200 | 1200 | 1200 |

Sound insulation capacity/dB | ≥35 | ≥40 | ≥42 | ≥45 |

Fire proof limit/h | ≥1 | ≥3 | ≥4 | ≥5 |

Heat transfer coefficient/w/m.k | ≤0.5 | |||

Radioactivity limit | ≤1.0 | |||

IRa(Inner radiation indexes) | ≤0.5 | |||

IR(Outer radiation indexes) | ≤0.5 | |||

4. Application & Projects

CMAX wall panels are widely used in partitions, assembly houses, villas, public buildings, commercial buildings, residential houses, firewall, fire-rated warehouse, cold storage, non-load-bearing walls, etc.

- Q: Polyurethane sandwich panel production line which part of the composition, where the polyurethane sandwich panel production line is better?

- Polyurethane composite insulation board production line complete sets of equipment, mainly by the open system, film cutting system, forming machine system, steel preheating furnace, high pressure foaming system, double track system, double track heating system, cutting system, horizontal cooling system, palletizing Systems, packaging systems and a series of equipment. Zhongji Machinery Manufacturing Co., Ltd. was established in 1992, won the title of national high-tech enterprises, and the Ministry of Commerce was identified as designated equipment export manufacturers. But the price is more expensive!

- Q: Color steel sandwich panel foam per cubic meter of weight is how much

- The national standard is 18kg. Color steel sandwich panels are common in the current building materials, not only can be a good flame retardant and environmentally friendly and efficient. Caigang sandwich board has two layers of metal panels and the middle of the polymer core insulation from the suppression. With the installation is simple, light and efficient light and efficient features. And the filling system used to close the molecular structure of the closed, you can put an end to the condensation of water vapor.

- Q: What is the current project wall, which kind of roof? There are commonly used models

- Sandwich board consists of three parts: the upper and lower two forming steel plate, the middle of the core board (with rock wool, polystyrene, polyurethane) thickness of 50mm / 75mm / 100mm, both sides of the strip. Mainly used for the activities of the wall panels and roof panels, and a variety of large factories. The color pressure plate is an integral part of the sandwich panel, that is, the upper and lower forming plates. Generally used for site Wai block, warehouse panel. The model wall is made of 950 rock wool wall sandwich panel composite board, roof 960 rock wool roof sandwich panel

- Q: What are the quality standards for color steel sandwich panels?

- Reference to national standards: GBT_23932-2009_ Building metal surface insulation sandwich panels

- Q: Aluminum magnesium manganese composite sandwich panel 90 degrees right angle how to fold

- Certainly the aluminum magnesium manganese plate light, the proportion of aluminum magnesium manganese plate is 4.71, the proportion of color steel plate is 7.85.

- Q: Flour mill production workshop, steel frame, roof with glass wool cotton sandwich panel (veneer) whether it can,

- I can answer; I can not use color steel to answer;

- Q: How to calculate the force of the sandwich panel

- Are generally estimated that we are doing this. Do not know how to calculate, but how many people we have to do the number of board

- Q: What is the latest export tax rebate rate for sandwich panels and color steel tiles? Thank you

- 3921199000 Other foam sheets, sheets, films, foils, strips Tax rebate rate 13% No regulatory conditions 7210700000 painted or coated iron or non-alloy steel wide sheet (width ≥ 600mm) Tax rebate rate 13% No regulatory conditions

- Q: Color steel sandwich panels and C steel belongs to what industry

- Should be considered building materials it Make the house with the thing.

- Q: What is the name of the board?

- Most of the use of polystyrene sandwich panels in the south (EPS sandwich panels), commonly known as sandwich panels, the middle of the bubble with us to buy electrical shock when the bubble is a material! In the north, especially the north of the Yellow River is now slowly began to use rock wool sandwich panels, rock wool fire and the insulation effect is very good, the disadvantage is easy to stimulate the skin when cutting the skin, there is a heavy weight!

Send your message to us

Easy install Fiber cement composite wall panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords