Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

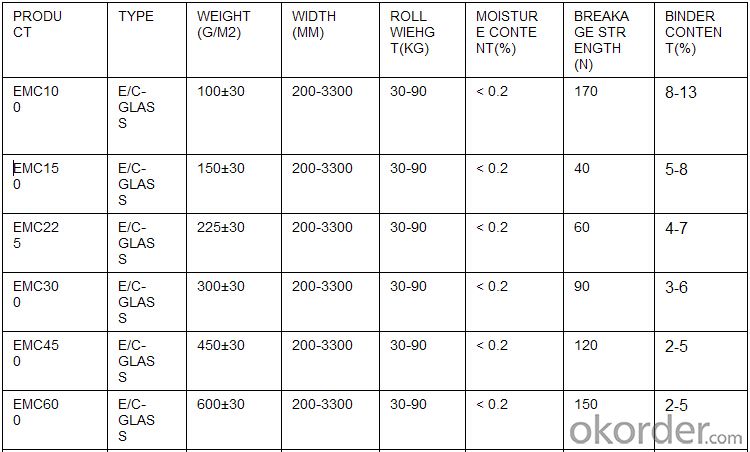

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Is fiberglass mat tissue fire-resistant?

- Yes, fiberglass mat tissue is fire-resistant.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue directly affects its transportation in terms of the ease and cost. Heavier rolls will require more effort and resources for handling, loading, and unloading. They may also require specialized equipment for transportation, leading to higher shipping costs. On the other hand, lighter rolls are easier to handle and transport, reducing the overall logistical challenges and expenses.

- Q: Can fiberglass mat tissue be used for insulating radiant floors?

- Yes, fiberglass mat tissue can be used for insulating radiant floors. Fiberglass is a popular insulation material due to its excellent thermal properties and resistance to moisture. Fiberglass mat tissue, in particular, is designed to provide additional strength and durability to the insulation layer. When used in radiant floor systems, it helps to prevent heat loss and improve energy efficiency by creating a barrier between the heated floor and the cooler ground or subfloor. Additionally, fiberglass mat tissue is easy to install and can be cut to fit any shape or size, making it a versatile choice for insulating radiant floors.

- Q: Does fiberglass mat tissue provide any sound insulation?

- Indeed, sound insulation is indeed provided by fiberglass mat tissue. This widely-used material finds application in diverse industries such as construction and automotive, where its purpose is to absorb and diminish sound transmission. By means of its fibrous composition, this material efficiently seizes and absorbs sound waves, effectively preventing their penetration through walls or other surfaces. Frequently employed as acoustic insulation, fiberglass mat tissue contributes to the creation of a pleasant and serene atmosphere in walls, floors, and ceilings.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. Fiberglass mat tissue is a versatile material that is commonly used in repairing and reinforcing fiberglass structures, including boats. It is designed to provide strength and durability, making it an ideal choice for patching holes, cracks, or damaged areas in fiberglass boat hulls. The mat tissue is typically layered with resin to form a solid and stable repair, ensuring that the boat remains structurally sound. Additionally, fiberglass mat tissue is easy to work with and can be cut to the desired size and shape, making it suitable for various repair applications on fiberglass boats.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Fiberglass mat tissue is indeed suitable for insulation in laboratories. It is a commonly used material for thermal insulation due to its excellent thermal properties. Fiberglass mat tissue has a high resistance to heat transfer, making it an effective insulator to maintain stable temperatures within laboratory spaces. Additionally, fiberglass mat tissue is also resistant to moisture, chemicals, and fire, which are crucial factors in laboratory settings. It can withstand exposure to harsh chemicals and does not degrade or lose its insulating properties over time. This makes it ideal for insulation in laboratories where various chemicals and substances are handled. Furthermore, fiberglass mat tissue is easy to install and can be customized to fit specific insulation requirements. It can be applied to walls, ceilings, and pipes to create a barrier that prevents the transfer of heat, ensuring a controlled environment within the laboratory. Overall, fiberglass mat tissue is a suitable choice for insulation in laboratories due to its thermal resistance, chemical resistance, fire resistance, and ease of installation. It helps to maintain stable temperatures, protects against chemical exposure, and ensures safety in laboratory environments.

- Q: Is fiberglass mat tissue fire resistant?

- Yes, fiberglass mat tissue is fire resistant.

- Q: What is the weight range of fiberglass mat tissue?

- The weight of fiberglass mat tissue can vary depending on the specific product and its intended application. Typically, the weight range of fiberglass mat tissue can be anywhere from approximately 20 grams per square meter (gsm) to over 100 gsm. Thinner and lighter fiberglass mat tissues are commonly employed for insulation purposes or as a reinforcing layer in composite materials. On the other hand, heavier fiberglass mat tissues are generally utilized for more demanding applications like roofing or flooring. It is worth noting that the weight range may also be influenced by factors such as the type of resin used, the desired strength or stiffness of the final product, and any specific requirements or specifications for a particular project.

- Q: How does fiberglass mat tissue compare to cellulose insulation?

- Fiberglass mat tissue and cellulose insulation differ in terms of material composition and insulation properties. Fiberglass mat tissue is made from fine glass fibers, while cellulose insulation is composed of recycled paper fibers treated with fire-retardant chemicals. Fiberglass mat tissue offers higher R-value, meaning it provides better thermal insulation and energy efficiency. Additionally, it is resistant to moisture and does not promote mold growth. On the other hand, cellulose insulation is more affordable, environmentally friendly, and provides better sound insulation. Ultimately, the choice between the two depends on specific insulation needs, budget, and environmental considerations.

- Q: Can fiberglass mat tissue be used for making lightweight doors?

- Yes, fiberglass mat tissue can be used for making lightweight doors. It is a lightweight material that offers excellent strength and durability, making it suitable for door construction. Additionally, fiberglass mat tissue can provide insulation properties and resistance to moisture, making it a viable option for lightweight door manufacturing.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords