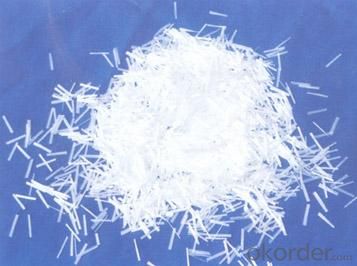

Fiberglass Chopped Strand e-glass Fiberglass for Thermoplastics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

E-Glass Fiber Glass Chopped Strands For Thermoplastics are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What are the different surface finishes available for fiberglass chopped strand?

- Fiberglass chopped strand offers a range of surface finishes to choose from. One commonly used option is a polyester resin, which gives the fiberglass a smooth and glossy appearance. This type of finish is ideal for applications where aesthetics play a crucial role, like in boat or automotive part manufacturing. Another choice is a gelcoat surface finish, a high-performance resin that provides a sturdy and protective layer to the fiberglass. This finish is suitable for applications exposed to harsh environmental conditions, such as swimming pool or water tank construction. Furthermore, there are surface finishes available with additives like pigments or fillers, offering specific properties to the fiberglass. For instance, an anti-slip surface finish can be applied for applications requiring good traction, like stairs or ramps. Ultimately, the selection of a surface finish for fiberglass chopped strand depends on the specific needs of the application, considering factors such as aesthetics, durability, and functionality.

- Q: How is fiberglass chopped strand used in the consumer goods industry?

- Fiberglass chopped strand is widely used in the consumer goods industry due to its versatile properties and numerous applications. It is primarily utilized in the manufacturing of various consumer goods to enhance their strength, durability, and overall performance. One common application of fiberglass chopped strand in the consumer goods industry is in the production of plastic products. By adding the chopped strands to the plastic matrix, it significantly improves the strength and rigidity of the final product. This is particularly beneficial for items such as automotive parts, electrical enclosures, and furniture components, where high strength is required to withstand heavy loads or external impacts. Additionally, fiberglass chopped strand is used in the production of appliances such as refrigerators, washing machines, and ovens. These appliances often require heat resistance and insulation properties, which can be achieved by incorporating chopped strands into their construction. The fiberglass reinforcement provides enhanced thermal stability, allowing the appliances to withstand high temperatures without deformation or structural damage. Another important application of fiberglass chopped strand in the consumer goods industry is in the manufacturing of sporting goods and recreational equipment. It is commonly used in the production of items like surfboards, kayaks, helmets, and bicycles, where the strength-to-weight ratio is crucial. The addition of chopped strands to the composite materials used in these products enhances their strength and resilience, making them more durable and reliable during intense physical activities. Furthermore, fiberglass chopped strand finds extensive use in the production of various household items, such as bathtubs, shower enclosures, sinks, and countertops. These products require resistance to moisture, chemicals, and impact, which can be achieved by incorporating chopped strands into their composite materials. The fiberglass reinforcement ensures that these consumer goods maintain their structural integrity and aesthetic appeal over time. In conclusion, fiberglass chopped strand plays a vital role in the consumer goods industry by providing enhanced strength, durability, and performance to a wide range of products. Its applications are diverse, spanning from plastic products, appliances, and sporting goods to household items. With its unique properties, fiberglass chopped strand is an essential component in the manufacturing process, ensuring that consumer goods meet the demands of modern consumers for high-quality and long-lasting products.

- Q: Is fiberglass chopped strand suitable for applications requiring high vibration resistance?

- Fiberglass chopped strand is well-suited for applications that require strong resistance to vibration. Fiberglass is renowned for its impressive mechanical properties, including its high tensile strength and stiffness. The chopped strand form presents added advantages, such as improved dispersion and easier handling during application. These qualities make fiberglass chopped strand an excellent material for applications exposed to intense vibration, like automotive parts, boat hulls, and aerospace components. The fibers' capacity to absorb and dissipate vibrations aids in reducing stress and preventing fatigue failure in these challenging environments. Furthermore, fiberglass chopped strand is extremely versatile and can be combined with other materials to further enhance its vibration resistance properties.

- Q: Is fiberglass chopped strand compatible with different manufacturing processes?

- Yes, fiberglass chopped strand is compatible with various manufacturing processes. It can be used in processes such as compression molding, injection molding, pultrusion, and filament winding, among others. Its versatility and ability to be easily incorporated into different manufacturing methods make it a popular choice in various industries.

- Q: Is fiberglass chopped strand compatible with different surface treatments?

- Different surface treatments are compatible with fiberglass chopped strand. Fiberglass chopped strand, being a versatile material, can be utilized with various surface treatments to enhance both its performance and appearance. Common surface treatments encompass painting, coating, laminating, and gel coating. These treatments serve to enhance the adhesion, durability, and resistance of the fiberglass against factors like UV radiation, chemicals, moisture, and abrasion. Moreover, the compatibility of fiberglass chopped strand with diverse surface treatments allows for customization and versatility in numerous applications, such as the automotive, construction, marine, and aerospace industries.

- Q: What are the typical health and safety considerations when working with fiberglass chopped strand?

- When working with fiberglass chopped strand, there are several typical health and safety considerations that should be taken into account: 1. Personal Protective Equipment (PPE): It is essential to wear the appropriate PPE when working with fiberglass chopped strand. This may include a respirator or dust mask to protect against inhalation of airborne particles, safety glasses or goggles to prevent eye irritation or injury, and gloves to protect the hands from potential skin irritation or cuts. 2. Ventilation: Adequate ventilation is crucial when working with fiberglass chopped strand. This helps to minimize the inhalation of airborne particles and reduce the concentration of potentially harmful fumes or dust in the work area. If working indoors, ensure that the area is well-ventilated, and if possible, use exhaust fans or other ventilation systems to remove airborne contaminants. 3. Handling and storage: Fiberglass chopped strand can have sharp edges, so it is important to handle it with care to avoid cuts or punctures. Proper storage of the material is also essential to prevent any accidental exposure or damage. Store the fiberglass chopped strand in a dry and secure location, away from heat sources or open flames. 4. Dust control: Fiberglass chopped strand can produce fine particles or dust during handling, cutting, or sanding. To minimize exposure to these particles, it is important to implement effective dust control measures. This may involve using wet methods, such as wet cutting or wet sanding, to reduce the generation of airborne dust. Additionally, using vacuum systems or dust collectors can help capture and contain any dust that is generated. 5. Training and awareness: Proper training and awareness are crucial when working with fiberglass chopped strand. All individuals working with this material should be educated on the potential hazards, proper handling techniques, and emergency response procedures. It is important to follow all safety guidelines and protocols to minimize the risk of injury or exposure to harmful substances. By considering these health and safety considerations, individuals can ensure a safer working environment when working with fiberglass chopped strand. It is always advisable to consult safety guidelines and regulations specific to your country or region to ensure compliance with local requirements.

- Q: Can fiberglass chopped strand be used in electrical transformers?

- No, fiberglass chopped strand is not typically used in electrical transformers. Electrical transformers require materials that have high electrical conductivity and low magnetic permeability, such as copper or aluminum. Fiberglass, on the other hand, is an insulating material that is commonly used for its high strength and resistance to heat and chemicals. While fiberglass may be suitable for other applications in electrical systems, it is not the preferred material for use in transformers due to its lack of electrical conductivity.

- Q: What is the difference between E-glass and S-glass chopped strands?

- The main difference between E-glass and S-glass chopped strands lies in their composition and properties. E-glass, or electrical glass, is primarily used for its electrical insulation properties and has a lower tensile strength compared to S-glass. On the other hand, S-glass, or structural glass, is known for its exceptional strength and stiffness, making it suitable for applications that require high mechanical performance. Therefore, the choice between E-glass and S-glass chopped strands depends on the specific requirements of the intended use.

- Q: Is fiberglass chopped strand compatible with polyurethane resin?

- Indeed, polyurethane resin and fiberglass chopped strand are a compatible duo. Polyurethane resin, being a versatile substance, can be utilized alongside various reinforcement fibers, fiberglass chopped strand included. This compatibility enables the production of robust and long-lasting composite goods. The fiberglass chopped strand imparts crucial strength and reinforcement, while the polyurethane resin functions as the matrix agent that binds the fibers together. This amalgamation yields a composite material that is lightweight, resilient against impact and corrosion, and possesses exceptional mechanical properties.

- Q: How does the dimensional stability of fiberglass chopped strand compare to other reinforcing materials?

- Fiberglass chopped strand is widely recognized for its exceptional dimensional stability, surpassing that of other reinforcement materials. Its remarkable resistance to moisture, temperature variations, and chemical exposure ensures its ability to retain its shape and structural integrity over extended periods. In contrast to steel or aluminum, fiberglass undergoes minimal expansion or contraction in the face of temperature fluctuations. Consequently, fiberglass components remain unaffected by warping, deformation, or alterations in their original dimensions amidst diverse environmental conditions. When compared to organic reinforcement materials like wood or natural fibers, fiberglass presents superior dimensional stability. Organic materials are susceptible to swelling, shrinking, or warping when exposed to moisture, heat, or fluctuations in humidity levels. Conversely, fiberglass remains largely impervious to these factors, establishing itself as a more dependable option for applications demanding critical dimensional stability. All in all, fiberglass chopped strand is widely regarded as one of the industry's leading choices for impeccable dimensional stability. Its consistency and durability over time render it highly favored for a broad spectrum of applications.

Send your message to us

Fiberglass Chopped Strand e-glass Fiberglass for Thermoplastics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords