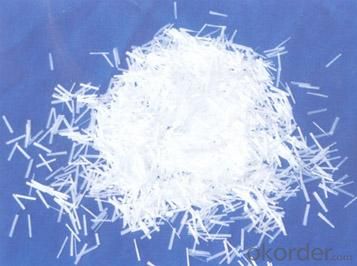

Chopped Strand Mat Fiberglass and Epoxy E Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Chopped Stands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP;

E-Glass Chopped Stands for thermoplastic are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product.

Product Features:

● Extremely low resin demand, delivering low viscosity to BMC paste

● High impact strength; High LOI rate

● High strand stiffness; Compatible with rubber

Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

● Special specification can be produce according to customer requirements.

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving depos

- Q: Can fiberglass chopped strand be used to reinforce concrete?

- Yes, fiberglass chopped strand can be used to reinforce concrete. It is commonly used as a replacement for traditional steel reinforcement due to its high tensile strength, corrosion resistance, and ease of handling and installation. The chopped strands are added to the concrete mix to improve its overall strength and durability.

- Q: How does the creep resistance of fiberglass chopped strand compare to other reinforcing materials?

- Fiberglass chopped strand is widely regarded as having superior creep resistance compared to many other reinforcing materials. It is renowned for its high tensile strength, enabling it to withstand significant loads without deformation over time. This resistance to creep is especially beneficial in applications where the material experiences constant or repetitive stress, such as in structural components or automotive parts. In terms of creep resistance, fiberglass chopped strand offers several advantages over other reinforcing materials like carbon fiber or steel. Although carbon fiber possesses a high strength-to-weight ratio, it is more susceptible to creep under sustained loads. On the other hand, steel exhibits excellent load-bearing capabilities but is prone to creep over time. With its unique combination of high tensile strength and low creep properties, fiberglass chopped strand provides a reliable and durable solution for various applications. Its resistance to creep ensures that the material will maintain its structural integrity and dimensional stability over an extended period. This makes it an ideal choice in industries where long-term performance is crucial, such as aerospace, construction, and marine sectors. Additionally, fiberglass chopped strand boasts high resistance to corrosion, setting it apart from materials like steel. This corrosion resistance allows it to be utilized in harsh environments or exposed to moisture without compromising its mechanical properties. In conclusion, the creep resistance of fiberglass chopped strand is generally superior to that of other reinforcing materials like carbon fiber or steel. Its high tensile strength, low creep properties, and corrosion resistance make it a reliable and durable choice for various applications.

- Q: How does the moldability of the chopped strand affect its performance?

- The performance of the chopped strand is significantly influenced by its moldability, which is the ability of the chopped strand to adapt and conform to the shape of the mold during the manufacturing process. When the chopped strand exhibits excellent moldability, it can effortlessly assume complex shapes with intricate details. This characteristic allows for its utilization in a wide array of applications that necessitate precise molding, including automotive parts, aerospace components, and consumer goods. Conversely, if the chopped strand possesses inadequate moldability, it can lead to various performance issues. It may fail to fully conform to the mold, resulting in gaps, voids, or uneven distribution of fibers. These issues can compromise the structural integrity and strength of the final product. Moreover, poor moldability can make it challenging to achieve consistent and uniform thickness, resulting in dimensional inaccuracies and variations in the finished product. Hence, the moldability of the chopped strand plays a crucial role in guaranteeing the overall performance and quality of the final product. By carefully selecting chopped strands with excellent moldability, manufacturers can achieve superior structural integrity, dimensional accuracy, and overall performance in their molded products.

- Q: How does the fiber alignment affect the electrical conductivity of fiberglass chopped strand composites?

- The fiber alignment in fiberglass chopped strand composites significantly affects the electrical conductivity of the material. The electrical conductivity of a composite material is directly related to the alignment of its reinforcing fibers. In fiberglass chopped strand composites, the fibers are randomly oriented and dispersed throughout the matrix. This random alignment creates a tortuous path for the flow of electrical current. As a result, the conductivity of the composite material is lower compared to materials with aligned fibers. When the fibers are aligned in a specific direction, such as in unidirectional composites, the electrical conductivity can be enhanced. In this case, the aligned fibers create a more direct and efficient pathway for the flow of electrical current. This alignment reduces the number of fiber-fiber crossovers, minimizing the resistance and improving the overall electrical conductivity of the composite. Additionally, the concentration and distribution of conductive fillers or additives within the composite matrix can also influence the electrical conductivity. By introducing conductive materials like carbon nanotubes or metal particles into the composite, the overall conductivity can be further enhanced, regardless of the fiber alignment. In summary, the fiber alignment plays a crucial role in determining the electrical conductivity of fiberglass chopped strand composites. Random fiber alignment creates a tortuous path, reducing conductivity, while aligned fibers provide a more direct pathway for electrical current flow, improving conductivity. The addition of conductive fillers can further enhance the electrical conductivity of the composite, regardless of fiber alignment.

- Q: Does fiberglass chopped strand improve the thermal conductivity of composite materials?

- No, fiberglass chopped strand does not improve the thermal conductivity of composite materials. In fact, fiberglass chopped strand is known for its low thermal conductivity, which makes it a popular choice for insulation applications. The strands are made of glass fibers that are randomly oriented and bonded together with a resin. This random orientation creates air pockets within the composite material, which reduces the transfer of heat and improves its insulating properties. Therefore, if the goal is to enhance the thermal conductivity of a composite material, alternative materials or modifications would need to be considered.

- Q: How is fiberglass chopped strand incorporated into composite materials?

- Fiberglass chopped strands are incorporated into composite materials by mixing them with a resin matrix, such as polyester or epoxy, and then applying pressure and heat to create a solid, strong, and durable composite. The chopped strands provide reinforcement and enhance the mechanical properties of the composite, making it suitable for various applications in industries like automotive, construction, and aerospace.

- Q: What are the advantages of using fiberglass chopped strand in the aerospace industry?

- The aerospace industry benefits from the use of fiberglass chopped strand in several ways. Firstly, fiberglass chopped strand is renowned for its high strength-to-weight ratio, which makes it an ideal material for constructing lightweight components for aircraft. This characteristic is crucial in the aerospace industry as it allows for fuel efficiency and increased payload capacity. Secondly, fiberglass chopped strand offers exceptional resistance to corrosion and chemicals, making it essential for aircraft that are exposed to harsh environmental conditions. This resistance ensures that the components have a long lifespan and are durable, reducing the need for frequent repairs or replacements. Moreover, fiberglass chopped strand possesses excellent electrical insulation properties, making it suitable for various electrical applications in aircraft. This insulation characteristic prevents any interference and promotes the safe and reliable operation of aerospace systems. Furthermore, fiberglass chopped strand is highly versatile and can be easily molded into complex shapes, enabling manufacturers to create intricate designs. This flexibility contributes to improved performance and reduced drag in aircraft, as aerodynamically efficient structures can be constructed. Additionally, fiberglass chopped strand has low thermal conductivity, which makes it an excellent choice for insulation purposes. This feature helps regulate the temperature within the aircraft, enhancing passenger comfort and reducing energy consumption. Lastly, fiberglass chopped strand is a cost-effective option compared to other materials used in the aerospace industry. Its availability and ease of manufacturing contribute to lower production costs, making it an attractive choice for aircraft manufacturers. In conclusion, the advantages of using fiberglass chopped strand in the aerospace industry include its high strength-to-weight ratio, resistance to corrosion and chemicals, electrical insulation properties, versatility in design, thermal insulation capabilities, and cost-effectiveness. These benefits make it the preferred material for constructing lightweight, durable, and efficient aircraft components.

- Q: Can fiberglass chopped strand be used in composite materials?

- Fiberglass chopped strand finds application in composite materials, offering reinforcement and durability. Comprising of small, randomly chopped glass fibers, it is commonly blended with resin to create composites. In numerous industries such as automotive, aerospace, construction, and marine, the use of fiberglass chopped strand is prevalent. Its efficacy and cost-effectiveness make it an ideal choice for enhancing the strength and stiffness of composites, rendering them suitable for diverse applications.

- Q: What are the typical post-processing treatments for fiberglass chopped strand composites?

- Typical post-processing treatments for fiberglass chopped strand composites include trimming excess material, sanding or grinding to achieve desired surface finish, applying gel coat or paint for aesthetics and protection, and sometimes adding additional layers of reinforcement or coating for improved strength or specific properties.

- Q: Can fiberglass chopped strand be used in water treatment tanks?

- Yes, fiberglass chopped strand can be used in water treatment tanks. Fiberglass is known for its excellent corrosion resistance and high strength-to-weight ratio, making it a suitable material for various applications in the water treatment industry. The chopped strand form of fiberglass can be used to reinforce the tanks, making them more durable and resistant to wear and tear. Additionally, fiberglass is non-reactive to water and does not leach any harmful substances, which is crucial for maintaining water quality in treatment tanks. Overall, fiberglass chopped strand is a reliable and effective material for use in water treatment tanks.

Send your message to us

Chopped Strand Mat Fiberglass and Epoxy E Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords