Fiberglass Mat Tissue - E-Glass Chopped Strand Mat for Sanitary Ware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-glass Chopped Strand Mat , Fiberglass Mat for Sanitary Ware

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

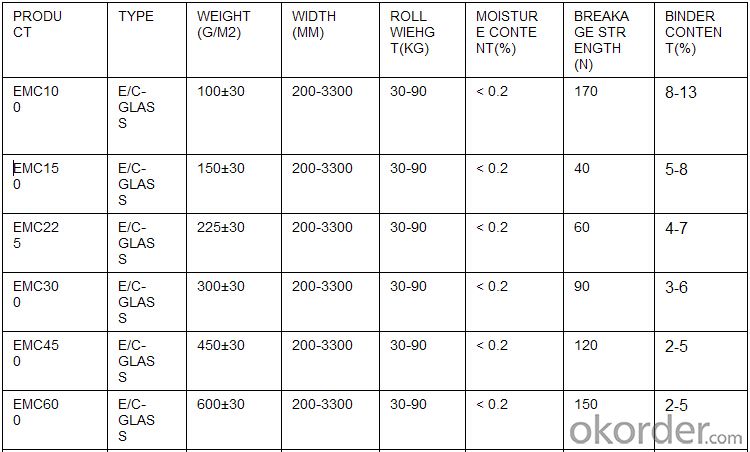

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: How long does fiberglass mat tissue last?

- The durability and longevity of fiberglass mat tissue can change depending on different factors, including its quality, usage, and exposure to external conditions. Typically, fiberglass mat tissue is designed to be highly durable and long-lasting. When installed and maintained correctly, it can endure for many decades. However, it is worth noting that fiberglass mat tissue can degrade over time due to environmental elements like UV exposure, moisture, and temperature fluctuations. Continuous exposure to harsh weather conditions, extreme temperatures, or chemicals can speed up the deterioration process. To maximize the lifespan of fiberglass mat tissue, it is vital to adhere to the manufacturer's guidelines for installation, maintenance, and regular inspections. Regular inspections can help detect any signs of wear, damage, or degradation early on, enabling timely repairs or replacements. For specific information regarding the expected lifespan of a particular fiberglass mat tissue and its intended application, it is advisable to seek advice from a professional or directly consult the manufacturer. The expected lifespan can vary depending on the specific product and its intended use.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Due to its inherent heat resistance properties, fiberglass mat tissue is highly effective in high temperatures. The mat is crafted from woven glass fibers, creating a durable and sturdy material. These glass fibers possess a high melting point, enabling the fiberglass mat tissue to endure elevated temperatures without distorting or compromising its structural integrity. Unlike other materials, fiberglass mat tissue does not shrink, warp, or become brittle when exposed to high temperatures. It maintains its dimensional stability and mechanical strength, making it suitable for a wide range of applications in industries such as automotive, aerospace, construction, and insulation. Furthermore, fiberglass mat tissue acts as a thermal insulator, providing protection against heat transfer. It effectively resists heat conduction and radiation, assisting in maintaining the desired temperature in a given environment or preventing heat damage to nearby components. Moreover, fiberglass mat tissue is non-combustible, meaning it does not burn or release toxic gases when subjected to fire. This characteristic makes it a dependable choice for applications that necessitate fire resistance, such as fireproofing insulation or protective barriers. In conclusion, fiberglass mat tissue excels in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature establish it as an outstanding material for demanding environments where elevated temperatures are present.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- The different reinforcement orientations available for fiberglass mat tissue include random chopped strand mat (CSM), continuous strand mat (CSM), woven roving, and unidirectional fiberglass.

- Q: What is fiberglass mat tissue?

- Fiberglass mat tissue, made from randomly oriented glass fibers bonded together with a binder, is a non-woven material used in construction, automotive, and aerospace industries. The primary function of fiberglass mat tissue is to reinforce and provide strength and durability to composite materials. It acts as a supportive layer between the glass fibers and resin, distributing stress and improving mechanical properties. Fiberglass mat tissue offers several advantages. It is lightweight, flexible, and easy to handle, making it suitable for complex shapes and curved surfaces. It also has excellent resistance to chemicals, moisture, and temperature changes, ensuring longevity in harsh environments. In construction, fiberglass mat tissue is commonly used in roofing materials, wall panels, and insulation boards. Its high strength-to-weight ratio makes it ideal for reinforcing concrete structures like bridges and buildings. In the automotive industry, fiberglass mat tissue enhances the structural integrity of car parts such as body panels, bumpers, and interior components, making them more resistant to impacts and vibrations. In aerospace, fiberglass mat tissue is utilized in the production of aircraft components like wings, fuselages, and interiors. Its lightweight nature contributes to fuel efficiency and weight reduction while maintaining necessary strength for safe flight. Overall, fiberglass mat tissue is a versatile and reliable material that plays a crucial role in enhancing the performance, durability, and safety of various products across industries. Its unique properties make it an indispensable component in the production of composite materials.

- Q: What are the different surface finishes available for fiberglass mat tissue?

- Some common surface finishes available for fiberglass mat tissue include smooth, textured, embossed, and matte finishes. These finishes can provide various aesthetic effects and enhance the performance of the fiberglass mat tissue in different applications.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is widely used in the production of sports equipment due to its unique properties and advantages. This material is a non-woven fabric made from fine glass fibers bonded together with a binder. It has a smooth texture and is lightweight, yet strong and durable. In the production of sports equipment, fiberglass mat tissue is typically used as a reinforcing layer. It helps to enhance the strength and rigidity of the final product, making it more resistant to impact and stress. This is particularly important in sports equipment where durability and performance are crucial, such as in the manufacturing of surfboards, skateboards, snowboards, and tennis rackets. When constructing a surfboard, for example, fiberglass mat tissue is commonly layered over a foam core and then impregnated with epoxy resin. This combination creates a strong and lightweight structure that can withstand the forces exerted by the waves. Similarly, in snowboards and skateboards, fiberglass mat tissue is applied to the wooden core to provide additional strength and stiffness, allowing for better control and responsiveness. Moreover, fiberglass mat tissue is also used in the manufacturing of protective gear like helmets and shin guards. By incorporating this material into the production process, these items can be made more impact resistant and capable of absorbing shocks. This is vital in sports where there is a high risk of injury, as the fiberglass mat tissue acts as a protective layer, dispersing and reducing the force of impacts. Overall, fiberglass mat tissue plays a crucial role in the production of sports equipment by reinforcing structures, enhancing strength and durability, and improving performance. Its lightweight nature combined with its superior mechanical properties makes it an ideal choice for various sporting applications, ensuring athletes can rely on their equipment to perform at their best while minimizing the risk of injury.

- Q: Can fiberglass mat tissue be used for making lightweight ceilings?

- Yes, fiberglass mat tissue can be used for making lightweight ceilings. Fiberglass mat tissue is a thin and lightweight material made from fiberglass strands that are bonded together with a binder. It is commonly used in construction and building applications due to its excellent strength-to-weight ratio. When used for making lightweight ceilings, fiberglass mat tissue can provide several advantages. Firstly, it is lightweight, which makes it easier to handle and install. This can save time and effort during construction or renovation projects. Additionally, fiberglass mat tissue is also known for its high tensile strength and durability, making it a suitable choice for ceilings that need to withstand various loads and stresses. Furthermore, fiberglass mat tissue has good thermal insulation properties, which can help in maintaining a comfortable indoor environment. It can also offer sound insulation benefits, reducing noise transmission between different spaces or floors. Moreover, fiberglass mat tissue is resistant to moisture, mold, and mildew, which makes it suitable for areas with high humidity or moisture concerns such as bathrooms or kitchens. It is also non-combustible, providing an added level of fire resistance to the ceiling structure. In conclusion, fiberglass mat tissue can indeed be used for making lightweight ceilings. Its lightweight nature, strength, durability, thermal and sound insulation properties, as well as resistance to moisture and fire, make it a suitable choice for various ceiling applications.

- Q: Is fiberglass mat tissue resistant to UV radiation?

- Indeed, fiberglass mat tissue exhibits remarkable resistance to UV radiation. Renowned for its exceptional ability to withstand UV rays, fiberglass proves highly suitable for outdoor uses. Over time, solar UV radiation can cause materials to deteriorate, change color, or become fragile. Nevertheless, fiberglass mat tissue is manufactured with a unique resin that imparts UV stability, enabling it to retain its strength and integrity even when exposed to prolonged sunlight. Consequently, fiberglass mat tissue has become widely favored for numerous outdoor applications, including roofing, boat construction, and exterior cladding. In these scenarios, it is crucial to employ a material that can endure the detrimental impacts of UV radiation.

- Q: Can fiberglass mat tissue be used for repairing fiberglass RVs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass RVs. Fiberglass mat tissue is a lightweight, flexible material that is commonly used for reinforcing and repairing fiberglass structures. It is designed to be easily molded and shaped to fit the contours of the damaged area, making it ideal for repairing RVs, which often have curved surfaces. To repair a fiberglass RV using fiberglass mat tissue, the damaged area needs to be cleaned and prepared by removing any loose or damaged fiberglass. The mat tissue is then cut to the appropriate size and shape to cover the damaged area. A suitable fiberglass resin or adhesive is applied to both the damaged area and the backside of the mat tissue. The tissue is then carefully placed over the damaged area and pressed down to ensure proper adhesion. Once the repair is complete, the fiberglass resin or adhesive is allowed to cure according to the manufacturer's instructions. After curing, the repaired area can be sanded, primed, and painted to match the rest of the RV's exterior. It is important to note that fiberglass mat tissue is typically used for smaller repairs and cosmetic damage. For larger structural repairs, it may be necessary to use additional reinforcement materials such as fiberglass cloth or woven roving. It is recommended to consult with a professional or refer to specific repair guides for detailed instructions on repairing fiberglass RVs.

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose potential health and safety concerns. The fine fiberglass particles present in the air during handling and cutting can be inhaled, leading to respiratory issues such as irritation, coughing, and difficulty breathing. Prolonged exposure to these particles may also result in long-term lung damage. Additionally, direct skin contact with the fiberglass can cause skin irritation and allergic reactions. Hence, it is important to use appropriate personal protective equipment, such as gloves, masks, and goggles, to minimize these risks and ensure a safe working environment.

Send your message to us

Fiberglass Mat Tissue - E-Glass Chopped Strand Mat for Sanitary Ware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords