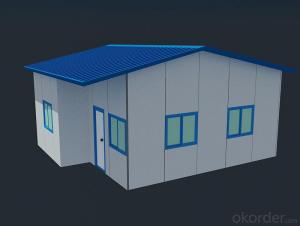

Durable EPS House for Project

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed introduction to EPS house:

1 Structure is reliable :Light steel structure system is safe and reliable ,satisfied modern architecture concept.

2 Easy assembly and disassembly : The house can be assembled and disassembled many times,used repeatedly. It just need simple tools to assemble .each worker can assemble 20-30 square meters every day ,6 worker can finish 300 sqm prefab house in 2 days.

3 Beautiful decoration : the prefab house is beautiful and grace ,have bright and bland colour , flat and neat board , with good decoration effect.

4 Flexible layout : Door and window can be assembled in any position , partition wall panel can be assemble in any transverse axes sites ,stair is assembled in outside.

5 Using life : All the light steel structures have antisepsis-spraying treatment.the normal using age are above 15 years.

6 Environmental protection and economy : Prefab house design is reasonable, easy to assemble and disassemble,used circularly,low wastage,without building rubbish. Average using costing is less than other kinds of building annually.

ITEM | SANDWICH PANEL | LENGTH THICKNESS | 950MM 50MM | ||||||

QUANTITY | 1M2 | DATE | 2013-12-4 | ||||||

ITEM | STANDARD | RESULT | MEMO | ||||||

| 1 | COLOR | Conformity in same batch | Conformity | Qualified | ||||

2 | CRACK | No | No | Qualified | |||||

3 | INDENTATION | Not obviously | Not obviously | Qualified | |||||

4 | SIZE | LENGTH | ±2mm | 51mm | Qualified | ||||

THICKNESS | ±20mm | 950mm | Qualified | ||||||

5 | DENSITY kg/m2 | >=10.5% | 10.8% | Qualified | |||||

6 | STRIPPING PERFORMANCE | >=85% | 87% | Qualified | |||||

7 | MPA | >0.1 | 0.11 | Qualified | |||||

CONCLUSION | Qualified | ||||||||

| | | | | | | | | | |

Note:

1.Price no including the transport and installation cost, no including foundation cost,floor and ceiling cost,water and electricity cost.

2.Validity: This quotation sheet is valid for 15 days due to the unstable RMB exchange rate.

3.Payment term:30% T/T deposit before production, the balance 70% T/T need to pay before delivery.

4.Packing:Flat pack.

5.Delivery time:15 days after receive the 30% deposit. (The quantity is less than 5000㎡)

6.All price not listed in above project need to calculate separately.

- Q: What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

- Q: Fire protection recommendations for color steel sandwich panels

- Color plate can fire from six aspects: First, the use of good fire performance rock wool as a core material, which is a permanent solution. Second, in the process of building, the core material to stay away from welding, gas welding and other fire operations; Third, in the course of the use of some heat, the fire should not be next to the steel plate, to maintain a certain distance. If you want to set the kitchen in the color steel room, you need to have insulation layer, the wall should be installed fireproof rock insulation layer; Fourth, the wire, the cable is best not to pass from the core material, if necessary to wear protective cover Tube, socket, switch box should be used metal galvanized box and the use of mounted method; Fifth, indoor and outdoor with a simple fire fighting equipment, conditional installation of fire alarm should be convenient to facilitate the rapid evacuation of personnel; At least 6 meters to maintain a safe distance. Insulating materials that are not strictly flame-retardant are not flammable but are self-igniting. Strict, scientific and effective management, so that the fire away from the flammable color steel plate sandwich filler material, is to prevent color steel room fire is one of the important ways.

- Q: What is the rigid polyurethane sandwich panel

- This is a Caigang sandwich panel, can be used as a roof structure of the roof and wall panels, with a large stiffness, than the pressure plate stiffness, thermal performance is also very good, and the polyurethane sandwich panel fire Performance is also good

- Q: I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

- Q: What is the latest export tax rebate rate for sandwich panels and color steel tiles? Thank you

- 3921199000 Other foam sheets, sheets, films, foils, strips Tax rebate rate 13% No regulatory conditions 7210700000 painted or coated iron or non-alloy steel wide sheet (width ≥ 600mm) Tax rebate rate 13% No regulatory conditions

- Q: Because it was not promptly cleared, after the wind and sun, it is difficult to clear, because the area is relatively large, a little bit of clean up by hand very difficult, which experts have any good way not?

- 2. Board protection form: complex PVC protective film 【Features】 1. Advantages: good fire resistance, sound insulation better. Yanmian Caigang sandwich panel Features: Caigang rock wool composite board products for the A-class fire board 1. Good fire performance:

- Q: Fire rock wool sandwich panels can continue to fire how much time

- It is recommended to use basalt mineral rock wool, this rock wool fiber slender, low slag content so good fire performance, resistant to 2.5 hours

- Q: Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- Do you need to make a flat beam or a triangle? Made flat can use H-beam, do the triangle can be used C-shaped double-fight. Depends on your specific requirements.

- Q: Will the rock wool sandwich board which manufacturers better?

- I know, you can consider Zhejiang Bo Ya building materials, production Yanmian sandwich panels, all kinds of sandwich panels,

- Q: What is the fire resistance time of the steel wool

- Light rock wool sandwich panels do not know, rock wool home glass magnesium can then reach more than 2 hours.

Send your message to us

Durable EPS House for Project

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords