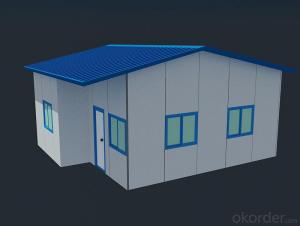

Two Floor Joined Durable EPS House

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed introduction to EPS house:

1 Structure is reliable :Light steel structure system is safe and reliable ,satisfied modern architecture concept.

2 Easy assembly and disassembly : The house can be assembled and disassembled many times,used repeatedly. It just need simple tools to assemble .each worker can assemble 20-30 square meters every day ,6 worker can finish 300 sqm prefab house in 2 days.

3 Beautiful decoration : the prefab house is beautiful and grace ,have bright and bland colour , flat and neat board , with good decoration effect.

4 Flexible layout : Door and window can be assembled in any position , partition wall panel can be assemble in any transverse axes sites ,stair is assembled in outside.

5 Using life : All the light steel structures have antisepsis-spraying treatment.the normal using age are above 15 years.

6 Environmental protection and economy : Prefab house design is reasonable, easy to assemble and disassemble,used circularly,low wastage,without building rubbish. Average using costing is less than other kinds of building annually.

ITEM | SANDWICH PANEL | LENGTH THICKNESS | 950MM 50MM | ||||||

QUANTITY | 1M2 | DATE | 2013-12-4 | ||||||

ITEM | STANDARD | RESULT | MEMO | ||||||

| 1 | COLOR | Conformity in same batch | Conformity | Qualified | ||||

2 | CRACK | No | No | Qualified | |||||

3 | INDENTATION | Not obviously | Not obviously | Qualified | |||||

4 | SIZE | LENGTH | ±2mm | 51mm | Qualified | ||||

THICKNESS | ±20mm | 950mm | Qualified | ||||||

5 | DENSITY kg/m2 | >=10.5% | 10.8% | Qualified | |||||

6 | STRIPPING PERFORMANCE | >=85% | 87% | Qualified | |||||

7 | MPA | >0.1 | 0.11 | Qualified | |||||

CONCLUSION | Qualified | ||||||||

| | | | | | | | | | |

Note:

1.Price no including the transport and installation cost, no including foundation cost,floor and ceiling cost,water and electricity cost.

2.Validity: This quotation sheet is valid for 15 days due to the unstable RMB exchange rate.

3.Payment term:30% T/T deposit before production, the balance 70% T/T need to pay before delivery.

4.Packing:Flat pack.

5.Delivery time:15 days after receive the 30% deposit. (The quantity is less than 5000㎡)

6.All price not listed in above project need to calculate separately.

- Q: Whether the rock wool sandwich panel is environmentally friendly

- How to say this, the board itself is environmentally friendly, the production process is not environmentally friendly ~

- Q: Level sandwich panels are not 820 type

- In fact this is nothing, JXB is not the first letter of the word sandwich panels. 42-333-1000 This is the sandwich panel on the upper and lower color plate model. For example: YX28-205-820 pressure wave height of 28MM wave width 205MM effective width is 820mm a look at this model is 4 wave color plate JXB42-333-1000 can explain: sandwich board which up and down a plate of the color plate 42MM pitch 333 effective use of the width of 1000 This model can be seen is 3 wave pressure plate. Sandwich panels are made of upper and lower color plate glue (foam) combination. The composition of the bubble is different, the name is also different, there are rock wool with polyurethane and so on

- Q: What is the difference between handmade rock wool sandwich panels and mechanism sandwich panels?

- As the name suggests, the inner layer is a foam board, thermal insulation but not set fire. The other is rock wool, thermal insulation, fire!

- Q: Build a color steel sandwich panel production plant how much money

- The general machine price of 25 million or so, the venue costs plus how much raw materials you need, you can run the general about 100 million, but the funds to return to the fast, can not have too much debt.

- Q: I know you can use fir pine wood and other materials, there are other plates can be made directly to furniture? Direct brush varnish to see the kind of texture

- Now the basic solid wood furniture are using the finished material, which can be considered genuine solid wood, and the logs are almost no. The other are MDF, particleboard outside the paste veneer, decorative panels, wood paper and then paint.

- Q: What kind of sandwich board is the phosphorous magnesium plate

- Magnesium board is a new type of multi-functional building materials. Using magnesium oxide, magnesium chloride as the main raw material, and a certain percentage of perlite, glass fiber mesh, wood fiber and other mixed processing. With light, fire, high strength, sound absorption, heat insulation, non-toxic harmless, corrosion-resistant, not mildew and so on. Can be used as a wall, ceiling ceiling, floor liner and so on.

- Q: Will the rock wool sandwich board which manufacturers better?

- I know, you can consider Zhejiang Bo Ya building materials, production Yanmian sandwich panels, all kinds of sandwich panels,

- Q: Caigang sandwich panel roof can be covered with oil felt leakproof?

- The roof can not heat

- Q: Color steel sandwich panel can do the widest, can be more than rice

- Can be a maximum of 1.1 meters

- Q: What is the name of the board?

- Most of the use of polystyrene sandwich panels in the south (EPS sandwich panels), commonly known as sandwich panels, the middle of the bubble with us to buy electrical shock when the bubble is a material! In the north, especially the north of the Yellow River is now slowly began to use rock wool sandwich panels, rock wool fire and the insulation effect is very good, the disadvantage is easy to stimulate the skin when cutting the skin, there is a heavy weight!

Send your message to us

Two Floor Joined Durable EPS House

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords