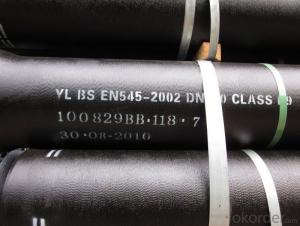

Ductile Cast Iron Short Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton pc

- Supply Capability:

- 50,000 Ton Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of DuctileIron Short Pipe:

•Material : Ductile Cast Iron

•Size Range : DN 80 to DN 2600

•Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

•Special requirements on external coating and internal lining can be applied

•We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Packaging & Delivery of Ductile Iron Short Pipe:

Packaging Detail: cases,pallets,or as customers' requirement

Delivery Detail: 30 days after orders

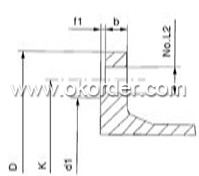

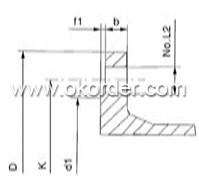

Ductile Iron Flange

Ductile Iron pipe is manufactured for water, steam, sewage, oil and other fluid lines where rigid joints are required. Flanged pipe is available in PN10, PN16 and PN25. Ductile flanged pipe is made in accordance with ANSI/AWWA C115/A21.15 and has a pipe wall thickness that provides for adequate metal under the threads.

Available in PN10, PN16 and PN25

Size: DN80-2000

Bolt holes shall be arranged symmetrically about the horizontal centerline through the flange faces

For Tees, this horizontal centerline is defined with the face of the brance flange held parallel to the vertical plane

PN10 Flange

Nominal Diameter DN | d1 | D | b | f1 | k | L2 | Bolt | Mass(kg) | |

Size | No. | ||||||||

80 | 132 | 200 | 16.0 | 3 | 160 | 19 | M16 | 8 | 2.9 |

100 | 156 | 220 | 16.0 | 3 | 180 | 19 | M16 | 8 | 3.3 |

150 | 211 | 285 | 16.0 | 3 | 240 | 23 | M20 | 8 | 5.1 |

200 | 266 | 340 | 17.0 | 3 | 295 | 23 | M20 | 8 | 7.1 |

250 | 319 | 400 | 19.0 | 3 | 350 | 23 | M20 | 12 | 9.8 |

300 | 370 | 455 | 20.5 | 4 | 400 | 23 | M20 | 12 | 12.9 |

350 | 429 | 505 | 20.5 | 4 | 460 | 23 | M20 | 16 | 14.7 |

400 | 480 | 565 | 20.5 | 4 | 515 | 28 | M24 | 16 | 17.7 |

450 | 530 | 615 | 21.5 | 4 | 565 | 28 | M24 | 20 | 20.2 |

500 | 582 | 670 | 22.5 | 4 | 620 | 28 | M24 | 20 | 24.3 |

600 | 682 | 780 | 25.0 | 5 | 725 | 31 | M27 | 20 | 33.7 |

700 | 794 | 895 | 27.5 | 5 | 840 | 31 | M27 | 24 | 46.3 |

800 | 901 | 1015 | 30.0 | 5 | 950 | 34 | M30 | 24 | 62.1 |

900 | 1001 | 1115 | 32.5 | 5 | 1050 | 34 | M30 | 28 | 73.0 |

1000 | 1112 | 1230 | 35.0 | 5 | 1160 | 37 | M33 | 28 | 92.9 |

1200 | 1328 | 1455 | 40.0 | 5 | 1380 | 40 | M36 | 32 | 138.0 |

1400 | 1530 | 1675 | 41.0 | 5 | 1590 | 43 | M39 | 36 | 174.7 |

1600 | 1750 | 1915 | 44.0 | 5 | 1820 | 49 | M45 | 40 | 241.8 |

1800 | 1950 | 2115 | 47.0 | 5 | 2020 | 49 | M45 | 44 | 281.9 |

2000 | 2150 | 2325 | 50.0 | 5 | 2230 | 49 | M45 | 48 | 336.5 |

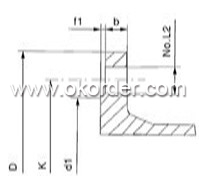

PN16 Flange

Nominal Diameter DN | d1 | D | b | f1 | k | L2 | Bolt | Mass(kg) | |

Size | No. | ||||||||

80 | 132 | 200 | 16.0 | 3 | 160 | 19 | M16 | 8 | 2.9 |

100 | 156 | 220 | 16.0 | 3 | 180 | 19 | M16 | 8 | 3.3 |

150 | 211 | 285 | 16.0 | 3 | 240 | 23 | M20 | 8 | 5.1 |

200 | 266 | 340 | 17.0 | 3 | 295 | 23 | M20 | 12 | 6.9 |

250 | 319 | 400 | 19.0 | 3 | 355 | 28 | M24 | 12 | 9.6 |

300 | 370 | 455 | 20.5 | 4 | 410 | 28 | M24 | 12 | 12.6 |

350 | 429 | 520 | 22.5 | 4 | 470 | 28 | M24 | 16 | 17.4 |

400 | 480 | 580 | 24.0 | 4 | 525 | 31 | M27 | 16 | 22.2 |

450 | 530 | 640 | 26.0 | 4 | 585 | 31 | M27 | 20 | 28.1 |

500 | 582 | 715 | 27.5 | 4 | 650 | 34 | M30 | 20 | 37.7 |

600 | 682 | 840 | 31.0 | 5 | 770 | 37 | M33 | 20 | 57.4 |

700 | 794 | 910 | 34.5 | 5 | 840 | 37 | M33 | 24 | 58.0 |

800 | 901 | 1025 | 38.0 | 5 | 950 | 40 | M36 | 24 | 77.0 |

900 | 1001 | 1125 | 41.5 | 5 | 1050 | 40 | M36 | 28 | 92.0 |

1000 | 1112 | 1255 | 45.0 | 5 | 1170 | 43 | M39 | 28 | 127.4 |

1200 | 1328 | 1485 | 52.0 | 5 | 1390 | 49 | M45 | 32 | 192.9 |

1400 | 1530 | 1685 | 55.0 | 5 | 1590 | 49 | M45 | 36 | 231.5 |

1600 | 1750 | 1930 | 60.0 | 5 | 1820 | 56 | M52 | 40 | 331.1 |

1800 | 1950 | 2130 | 65.0 | 5 | 2020 | 56 | M52 | 44 | 393.7 |

2000 | 2150 | 2345 | 70.0 | 5 | 2230 | 62 | M62 | 48 | 474.5 |

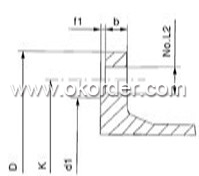

PN25 Flange

Nominal Diameter DN | d1 | D | b | f1 | k | L2 | Bolt | Mass(kg) | |

Size | No. | ||||||||

80 | 132 | 200 | 16 | 3 | 160 | 19 | M16 | 8 | 2.9 |

100 | 156 | 235 | 16 | 3 | 190 | 23 | M20 | 8 | 3.8 |

150 | 211 | 300 | 17 | 3 | 250 | 28 | M24 | 8 | 6.1 |

200 | 274 | 360 | 19 | 3 | 310 | 31 | M24 | 12 | 8.9 |

250 | 330 | 425 | 21.5 | 3 | 370 | 31 | M27 | 12 | 13.2 |

300 | 389 | 485 | 23.5 | 4 | 430 | 34 | M27 | 16 | 18.0 |

350 | 448 | 555 | 26.5 | 4 | 490 | 37 | M30 | 16 | 25.3 |

400 | 503 | 620 | 28 | 4 | 550 | 37 | M33 | 16 | 33.2 |

450 | 548 | 670 | 30.5 | 4 | 600 | 37 | M33 | 20 | 39.0 |

500 | 609 | 730 | 32.5 | 4 | 660 | 37 | M33 | 20 | 48.3 |

600 | 720 | 845 | 37 | 5 | 770 | 40 | M36 | 20 | 69.2 |

Ductile Iron Flanged Pipe

Flanged pipes with screwed-on flanges, Flanged pipes with cast-on flanges, Flanged pipes with welded-on flanges are available

Flanged pipes with screwed-on flanges, K9 K10 DN80-DN600, Length to be specified

Flanged pipes with cast-on flanges, K12 DN1200-2000, L≤4000mm

Flanged pipes with welded-on flanges, K9 K10, DN80-DN1000, Length to be specified

Nominal Diameter DN | Body |

| ||||||||

k=9 | k=10 | k=12 | Each Flange | |||||||

e mm | kg/m | e mm | kg/m | e mm | kg/m | PN10 | PN16 | PN25 | PN40 | |

80 | 6 | 12.2 | 6 | 12.2 | 7 | 14.1 | 3.6 | 3.6 | 3.5 | 3.5 |

100 | 6.1 | 15.1 | 6.1 | 15.1 | 7.2 | 17.7 | 4.2 | 4.2 | 4.5 | 4.5 |

150 | 6.3 | 22.8 | 6.5 | 23.5 | 7.8 | 28 | 6.3 | 6.3 | 7.1 | 9.2 |

200 | 6.4 | 30.6 | 7 | 33.3 | 8.4 | 39.7 | 8.8 | 8.6 | 10.4 | 15.7 |

250 | 6..8 | 40.2 | 7.5 | 44.3 | 9 | 52.8 | 12 | 11.8 | 15.3 | 25.4 |

300 | 7.2 | 50.8 | 8 | 56.3 | 9.6 | 67.3 | 16.8 | 16.6 | 20.8 | 36.3 |

350 | 7.7 | 63.2 | 8.5 | 69.6 | 10.2 | 83.1 | 23 | 25.5 | 29.0 | - |

400 | 8.1 | 75.5 | 9 | 83.7 | 10.8 | 100 | 26.5 | 31 | 37.4 | - |

500 | 9 | 104.3 | 10 | 115.6 | 12 | 138.2 | 41 | 54 | 54.5 | - |

600 | 9.9 | 137.1 | 11 | 152 | 13.2 | 181.8 | 56 | 79.8 | 79.1 | - |

700 | 10.8 | 173.9 | 12 | 193 | 14.4 | 230.8 | 72.5 | 84.2 | - | - |

800 | 11.7 | 215.2 | 13 | 238.7 | 15.6 | 285.5 | 102 | 117 | - | - |

900 | 12.6 | 260.2 | 14 | 288.7 | 16.8 | 345.4 | 118.5 | 137.5 | - | - |

1000 | 13.5 | 309.3 | 15 | 343.2 | 18 | 410.6 | 135 | 169.4 | - | -- |

1200 | 15.3 | 420.1 | 17 | 466.1 | 20.4 | 557.8 | 180 | 235 | - | - |

1400 | 17.1 | 547.2 | 19 | 607.2 | 22.8 | 726.8 | 253 | 301 | - | - |

1600 | 18.9 | 690.3 | 21 | 766 | 25.2 | 916.9 | - | - | - | - |

1800 | 20.7 | 850.1 | 23 | 943.4 | 27.6 | 1129.3 | - |

| - | - |

2000 | 22.5 | 1026.3 | 25 | 1139 | 30 | 1363.4 | - | - | - | - |

Usage of Ductile Iron Short Pipe:

A connection is commonly used in pipe installation with fitting, connect two of the same or different nominal diameter pipes

- Q: What is the reason that the rubber hose of the fire hose is flowing black oil?

- This is the groove of the fire trench, the connection of the pipeline meets all the requirements and the quality is not satisfied. That is, the quality of aprons.

- Q: As shown in Figure six, the angle of the edge distance 71mm, diagonal 80mm, about 34mm high; and its connection of the pipe joint exposed a small section, measured its outer diameter is 57mm; through these parameters can see the pipe joint screw size is how much? Or see the specifications of the hose.To take something in this, it is not convenient to disassemble temporarily, that can check through standard size, I do not know the check which standard, hose and pipe joint standards are many, I do not call up this kind... Please explain to the master, this call what, check what standard, how to check, through the above parameters can get out what size, etc., thank you very much!! PS: the key is size. Now you're going to do the connection

- Two. Metric general threads1. metric screw thread with a capital M, tooth type angle 2 degrees =60 (alpha tooth type half angle);2. metric ordinary thread by pitch, coarse teeth, ordinary thread and fine teeth, two kinds of ordinary thread;2.1. coarse tooth ordinary thread mark generally does not indicate the pitch, such as M20 means coarse thread; fine tooth thread mark must indicate the pitch, such as M30 * 1.5 for fine tooth thread, in which pitch is 1.5.2.2. common thread is used for the connection and fastening between the mechanical parts, and the general thread connection is mainly made of coarse thread. The thread strength of the fine tooth thread is slightly higher than that of the same nominal diameter, and the self-locking performance is better.Mark 3. metric screw thread: M20-6H, M20 * 1.5LH-6g-40, where M represents a common thread metric, 20 nominal diameter thread is 20mm, 1.5 pitch, LH said, 6G 6H left, said thread precision grade, precision grade of internal thread uppercase, lowercase precision grade of said external thread, 40 screwing length.

- Q: Well I've been looking to build a boat for quite awhile. I'm 14.. I know I can, but my problem is money. I've been looking to build the Bingo but I'm concerned about the trustworthy ness of the site and if I go as cheap as possible while still doing it right, how much money will it cost me? I have a TON of questions, but I'll just leave it at those for now.thanks.

- In a moving fluid I would have to say yes. Even a frictionless bend must induce turbulence and some energy loss.

- Q: What is the function of the pipe joint?

- Hydraulic term is a part of a hydraulic system that connects the pipe or sets the line to the hydraulic element

- Q: Inspired by another question I asked just recently.

- Remove the smoke detector and replace it with another. You said there was a smell coming from the heater. When you had it repaired there may have been some oil that has dripped on the burner and if that is happening that could be your problem. Take the heater back to the repairman or call first and he should turn the heater on and correct the problem. Jo Ann

- Q: one of my pipes froze and busted. I need to turn my water back on before other pipes freeze. can I change out the pipe while it's still frozen so I can go ahead and turn my water back on? thanks in advance

- lead is now only used in rain water systems so no portable water lead fittings are sold any more their are lead to copper fittings sold so you can convert to copper other than that no fittings made of lead are made

- Q: So not too long ago, I was watching the people in the kitchen at Carl's Jr making the food. I noticed they were using their bare hands. I thought they were supposed to be wearing gloves?

- It started about 5000 years ago. No, that is not a typo. From the copper development association, The craftsmen who built the great pyramid for the Egyptian Pharaoh Cheops fashioned copper pipe to convey water to the royal bath. That was indeed, over 5000 years ago. It was at the end of the 1920s that copper was first introduced in the U.S. as supply pipeing, and before that cast iron had replaced the very first systems which were wood. Yup, wood. From comes this little tidbit - In old construction, lead plumbing was common. It was generally eclipsed toward the end of the 1800s by galvanized iron water pipes which were attached with threaded pipe fittings. Higher durability, and cost, systems were made with brass pipe and fittings. Copper with soldered fittings became popular around 1950, though it had been used as early as 1900. Plastic supply pipes have become increasingly common since about 1970, with a variety of materials and fittings employed, however plastic water pipes do not keep water as clean as copper and brass piping does. Copper pipe plumbing is bacteriostatic. This means that bacteria can't grow in the copper pipes. Plumbing codes define which materials may be used, and all materials must be proven by ASTM, UL, and/or NFPA testing. So it isn't exactly clear when each type was first introduced as many different types overlaped each other, but in general, and concidering *modern* as being after 1900, galvanized was probably more frequently used than copper, even though copper goes back much further. Al

- Q: I've got an 6 speed, 2 wheel drive, 2008 Jeep Sahara Unlimited and I need snow chains or cables for my tires. My tires are 255/70/18 and need best to know what works awesome for Icy/snow roads?

- Its not easily done. The fittings allow a lap joint which is then soldered making a very strong and robust joint. What you are proposing would create a butt joint and they are very weak. There are some types of rubber boots that might allow this to be done but I've not seen anything exactly like what you are requesting.

- Q: How to use the clamp type pipe joint?

- The clamping sleeve type straight through joint has clamps at both ends, and it is worn at the end of the pipe which needs to be connected, and then it is clamped and connected with the nut,

- Q: In January Unemployment was at 8.6%. Any one want this Roller Coaster ride from the Rubber Band man for the next four years. Not ME, I happen to like Living with Food to Eat. Maybe Fluke and Obama should elope in Aruba. Now that's a thought. Sources:Love Roller Coaster - The Ohio PlayersUnemployment in the Bldg Construction Industry has been at 13% for the last 3 years - Ken Langone Founder of Home DepotRubber Band Man - The Spinners

- It sounds like a perfect tank for him. These fish like to fight with other beta's so I think he'll enjoy seeing his reflection plus he'll be more active.

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Cast Iron Short Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton pc

- Supply Capability:

- 50,000 Ton Per Year pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords