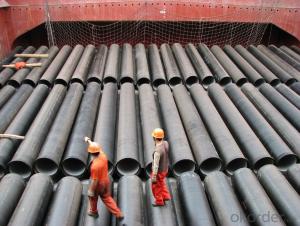

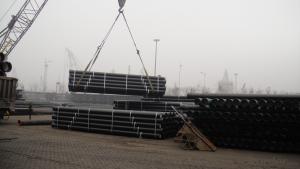

Ductile Iron Pipe On Sale From China For WaterProject with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Can ductile iron pipes be used for underground steam distribution systems?

- Yes, ductile iron pipes can be used for underground steam distribution systems. Ductile iron has excellent strength, durability, and resistance to high temperatures, making it suitable for carrying steam underground. Additionally, its corrosion resistance properties ensure a longer lifespan and reduced maintenance costs.

- Q: Can ductile iron pipes be used for trench crossings?

- Yes, ductile iron pipes can be used for trench crossings. Ductile iron pipes are known for their high strength and durability, making them suitable for various applications including trench crossings. They have the ability to withstand heavy loads and provide increased resistance to external forces, making them a reliable choice for such purposes.

- Q: What are the different methods for tapping ductile iron pipe?

- There are several methods for tapping ductile iron pipe, including hot tapping, mechanical tapping, and electrofusion tapping. Hot tapping involves drilling into the pipe while it is still in service and creating a connection without interrupting the flow. Mechanical tapping uses mechanical equipment to create a threaded or grooved connection on the pipe. Electrofusion tapping uses an electrofusion saddle to create a connection by fusing a fitting onto the pipe.

- Q: How much is the installation of cast iron pipe drainage 1 meters?

- From the tightness and corrosion resistance, ductile pipe sealing better after installation, but also can improve the corrosion resistance of corrosion protection through a variety of means; from the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve more runoff large; from the installation and maintenance cost, ductile pipe have more favorable price. The inner wall of zinc spray, anti-corrosion materials such as cement mortar.

- Q: Can ductile iron pipes be used in areas with high soil settlement?

- Yes, ductile iron pipes can be used in areas with high soil settlement. Ductile iron pipes are known for their strength and durability, which makes them suitable for various soil conditions, including areas with high soil settlement. These pipes have the ability to withstand external loads and ground movement, making them an ideal choice for such areas. Additionally, ductile iron pipes have a high resistance to corrosion, which further enhances their suitability for use in areas with high soil settlement. However, it is important to consider factors such as proper installation techniques, appropriate bedding and backfill materials, and regular maintenance to ensure the longevity and performance of the ductile iron pipes in areas with high soil settlement. Consulting with a qualified engineer or pipe manufacturer can provide more specific guidance based on the site's conditions and requirements.

- Q: Can ductile iron pipes be used for stormwater drainage?

- Yes, ductile iron pipes can be used for stormwater drainage. Ductile iron pipes are known for their strength and durability, making them suitable for various applications, including stormwater drainage systems. These pipes have high tensile strength and can withstand heavy loads and pressure, making them ideal for carrying large volumes of stormwater. Additionally, ductile iron pipes have a smooth interior surface that reduces friction and allows for efficient flow of water, minimizing the risk of blockages and clogging. With proper installation and maintenance, ductile iron pipes can provide a reliable and long-lasting solution for stormwater drainage.

- Q: Do ductile iron pipes require internal linings or coatings?

- Yes, ductile iron pipes typically require internal linings or coatings in order to prevent corrosion and extend their lifespan.

- Q: Are ductile iron pipes suitable for wastewater systems?

- Yes, ductile iron pipes are suitable for wastewater systems. Ductile iron is a strong and durable material that is resistant to corrosion and can withstand the harsh conditions often found in wastewater systems. It has a high tensile strength, which allows it to handle the pressure and stress caused by the flow of wastewater. Additionally, ductile iron pipes are easy to install and have a long lifespan, making them a cost-effective choice for wastewater systems. Overall, ductile iron pipes are a reliable and suitable option for carrying wastewater in various applications.

- Q: What kind of valves are commonly used in ductile iron pipes?

- Gate valve, butterfly valve, globe valve, check valve flange of various valves, (but the pipeline used for water supply and some limitations of the transport medium may be prescribed valve type) now due to material improvements in the technology, in most cases, smaller pipe diameter is also large diameter pipe outlet valve, butterfly valve, because of the pipeline the large diameter pressure in the pipeline and water than the small caliber to open and close the valve, to human hard, efficiency is not high, so for butterfly valve,

- Q: Can ductile iron pipes be used for river crossings?

- Yes, ductile iron pipes can be used for river crossings. Ductile iron is a strong and durable material that is capable of withstanding the pressure and stress of being buried and crossed by a river. It is commonly used for various applications, including water and sewage systems, and has been proven to be reliable for river crossings. However, it is important to consider other factors such as the depth of the river, the size and weight of the pipes, and the installation process to ensure the proper design and installation of the ductile iron pipes for river crossings.

Send your message to us

Ductile Iron Pipe On Sale From China For WaterProject with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords