Ductile Iron Pipe ISO 2531 / EN 545 K9,

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200

- Supply Capability:

- 9999 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets

accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market,

such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

·High yield strength

·High tensile Strength

·High corrosion resistance

·Pressure Resistence

·Anti-corrosion

·Installation is convenient

·Satisfy the highest hygienic standards

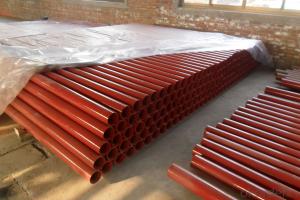

3,Ductile Iron Pipe Images:

4.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Can ductile iron pipes be used for underground irrigation systems?

- Yes, ductile iron pipes can be used for underground irrigation systems. Ductile iron is a strong and durable material that is resistant to corrosion and can withstand the pressure and load requirements of irrigation systems. It is commonly used in underground applications due to its longevity and reliability.

- Q: Do ductile iron pipes require internal linings for potable water?

- No, ductile iron pipes do not require internal linings for potable water. Ductile iron is a type of iron that has been treated to enhance its strength and flexibility. It is commonly used for water distribution systems due to its durability and resistance to corrosion. Unlike other materials, such as cast iron or steel, ductile iron pipes have a protective layer called a cement-mortar lining, which provides an effective barrier against corrosion and prevents the leaching of any harmful substances into the water. This lining is applied during the manufacturing process and is designed to withstand the corrosive properties of potable water, making internal linings unnecessary. Additionally, the smooth surface of ductile iron pipes helps to maintain the quality and flow of water without the need for additional linings.

- Q: Are ductile iron pipes suitable for railway crossings?

- Yes, ductile iron pipes can be suitable for railway crossings. Ductile iron is a strong and durable material that has been widely used in various applications, including water and sewage systems. Its high tensile strength and flexibility make it suitable for withstanding heavy loads and vibrations, which are common near railway crossings. Furthermore, ductile iron pipes have excellent resistance to corrosion, which is crucial in areas prone to moisture and exposure to different weather conditions. This resistance ensures the longevity of the pipes, reducing maintenance and replacement costs. Additionally, ductile iron pipes are known for their ease of installation and versatility. They can be easily connected with other types of pipes or fittings, allowing for a seamless integration into the overall railway crossing infrastructure. It is important to note that the suitability of ductile iron pipes for railway crossings also depends on various factors such as load requirements, soil conditions, and specific project specifications. Consulting with engineering professionals and adhering to industry standards and regulations is essential to ensure the appropriate selection and installation of ductile iron pipes for railway crossings.

- Q: What are the disadvantages of using ductile iron pipes?

- There are several disadvantages associated with using ductile iron pipes in various applications. Firstly, ductile iron pipes tend to be more expensive compared to other types of pipes, such as PVC or HDPE. This can be a significant drawback for projects with budget constraints. Secondly, ductile iron pipes are relatively heavy, which makes transportation and installation more labor-intensive and time-consuming. This can increase the overall cost of the project, especially when considering the need for specialized equipment and a skilled workforce. Another disadvantage is that ductile iron pipes are susceptible to corrosion. Over time, exposure to various environmental factors, such as soil conditions and water chemistry, can lead to the formation of rust and scale on the inner and outer surfaces of the pipe. This can reduce the pipe's lifespan and potentially affect water quality. Furthermore, ductile iron pipes can be prone to cracking or breaking under certain conditions, especially if exposed to heavy loads or significant ground movement. This can result in costly repairs or replacements, leading to additional expenses and disruptions to the water supply. Lastly, ductile iron pipes have a relatively low resistance to impact and abrasion compared to some other materials. This means they may be more prone to damage from external forces, such as construction activities or accidental impacts, which can further increase maintenance and repair costs. Overall, while ductile iron pipes have their advantages, such as high tensile strength and durability, it is important to consider these disadvantages before deciding on their use in a particular project.

- Q: Luo what effect of ductile cast iron

- Chromium is an anti graphitization element, which hinders the graphitization process of cast iron, increases the content of cementite (Fe3C) in the internal structure of cast iron, and stabilizes pearlite at the same time. It affects the mechanical and processing properties of nodular cast iron.

- Q: What is the weight of ductile iron pipe compared to other pipe materials?

- Ductile iron pipe is generally heavier compared to other pipe materials. Its weight can vary depending on the size and thickness of the pipe, but generally, ductile iron pipe is denser and has a higher weight per unit length compared to materials like PVC, HDPE, or steel. This higher weight of ductile iron pipe is primarily due to its composition, which includes iron and carbon, making it a sturdy and durable option for various piping applications.

- Q: Can ductile iron pipe be used for stormwater systems?

- Ductile iron pipe is indeed suitable for stormwater systems. This material is widely utilized in various applications, including stormwater systems, due to its strength and durability. Its exceptional corrosion resistance makes it ideal for managing stormwater, which frequently contains debris and chemicals. Moreover, ductile iron pipe possesses impressive tensile strength, enabling it to withstand significant amounts of pressure and weight. Therefore, it is a dependable option for stormwater systems that may encounter substantial flow rates and occasional surges. Furthermore, ductile iron pipe is accessible in a variety of sizes and configurations, providing flexibility and adaptability when designing stormwater systems.

- Q: How does ductile iron pipe handle ground movement and settlement?

- Ductile iron pipe is known for its excellent ability to handle ground movement and settlement. Due to its inherent strength and flexibility, it can withstand significant ground shifts without experiencing major damage or failure. One of the key features of ductile iron pipe is its high tensile strength, which allows it to withstand external forces and pressures. This strength enables the pipe to resist the effects of ground movement, such as soil settlement, subsidence, or shifting due to seismic activity. Moreover, ductile iron pipe has inherent flexibility, which allows it to absorb and distribute stress caused by ground movement. The pipe's flexibility helps to minimize the impact of settlement by allowing it to adjust and adapt to changes in the surrounding soil. This characteristic helps prevent the pipe from cracking, breaking, or leaking when the ground shifts or settles. Additionally, ductile iron pipes are often installed with flexible joints, such as push-on or mechanical joints, which further enhance their ability to accommodate ground movement. These joints provide a degree of flexibility and movement, allowing the pipe to adjust to changes in the soil without experiencing stress concentrations or structural failure. Furthermore, ductile iron pipe is highly resistant to corrosion, which is another important factor in its ability to handle ground movement and settlement. Corrosion can weaken pipes and make them more susceptible to damage during ground shifts. However, the corrosion-resistant properties of ductile iron help maintain the pipe's structural integrity and durability, even in challenging soil conditions. In summary, ductile iron pipe is well-suited to handle ground movement and settlement due to its high tensile strength, flexibility, and corrosion resistance. These properties allow the pipe to withstand external forces and adapt to changes in the surrounding soil, minimizing the risk of damage, leaks, or failure.

- Q: Ductile iron pipe joint leakage

- After cleaning the pipe mouth, the cf-2000 high efficiency composite waterproof agent is used to seal it, and it will not leak.

- Q: What are the different types of linings available for ductile iron pipe?

- There are several different types of linings available for ductile iron pipe, each with its own advantages and applications. 1. Cement mortar lining: This is one of the most common linings used for ductile iron pipes. It consists of a layer of cement mortar applied to the interior surface of the pipe. Cement mortar lining provides excellent resistance to corrosion and chemical attack, making it suitable for a wide range of applications, including potable water distribution, wastewater conveyance, and industrial pipelines. It also helps to reduce friction and turbulence within the pipe, improving flow efficiency. 2. Polyethylene lining: Polyethylene linings are often used in ductile iron pipes for applications where corrosion resistance is a primary concern. This lining consists of a layer of high-density polyethylene (HDPE) that is either extruded or sprayed onto the pipe's inner surface. Polyethylene lining provides superior resistance to corrosion, abrasion, and chemical attack, making it ideal for transporting aggressive fluids, such as saltwater, chemicals, or industrial waste. 3. Polyurethane lining: Polyurethane linings are commonly used in ductile iron pipes for applications where enhanced protection against abrasive wear is required. This lining is formed by spraying or pouring a layer of polyurethane onto the inner surface of the pipe. Polyurethane lining offers excellent resistance to abrasion, impact, and chemical attack, making it suitable for conveying abrasive slurries, mining applications, and other high-wear environments. 4. Epoxy lining: Epoxy linings are applied to ductile iron pipes to provide a protective barrier against corrosion and chemical attack. This lining is typically formed by applying a layer of epoxy resin to the pipe's inner surface through a process known as centrifugal casting or electrostatic spraying. Epoxy lining offers excellent adhesion and resistance to corrosion, making it suitable for various applications, including potable water distribution, wastewater treatment, and industrial pipelines. 5. Zinc lining: Zinc linings are used in ductile iron pipes to provide cathodic protection against corrosion. This lining involves applying a layer of zinc to the pipe's inner surface, either through hot-dip galvanizing or by electroplating. Zinc lining acts as a sacrificial anode, corroding preferentially to the iron pipe and protecting it from corrosion. It is commonly used in applications where the pipe is exposed to highly corrosive environments, such as seawater or acidic soils. Overall, the choice of lining for ductile iron pipes depends on the specific requirements of the application, including the type of fluid being transported, the level of corrosion resistance needed, and the potential for abrasive wear. Consulting with industry experts and considering factors such as cost, longevity, and maintenance requirements can help determine the most suitable lining option for a particular project.

Send your message to us

Ductile Iron Pipe ISO 2531 / EN 545 K9,

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200

- Supply Capability:

- 9999 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords