Ductile Iron Pipe DN80-DN800 K9 EN545 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market, such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

6. Internal Lining: Cement, conform to ISO4179

7. External coating: Zinc + Bitumen, conform to ISO8179

8. Rubber: NBR, SBR, EPDM according to ISO4633 / EN681.1

9. Note: The gaskets, bolts & nuts are supplied respectively as your special requirement

10.Service

• Drawing: we can translate your original drawing, offer best suggestion on design

• Quality: we have full set quality control system to guarantee the best quality.

• Inspection: inspect in house, all our products must be checked 3 times before packing

11.Inspection

• In-house Foundry

• Third party inspection available upon requirement

12.Our goal

• To be your preferred partner

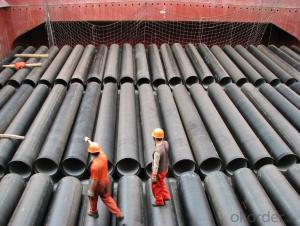

3,Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Place of Origin: China (Mainland)

Model Number: DN80-1600

Length: 6M/5.7M/NEGOTIATED

Standard: ISO2531 / EN545

Application: Potable/Sewage Water

Diameter: DN80-1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: standerd

Pull Strength: 420

Yield (≥ MPa): 300

Material: Ductile Iron

water ductile iron pipe: SO2531 / EN545 DI pipe

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Are ductile iron pipes suitable for installation in areas with high seismic activity?

- Ductile iron pipes are a suitable choice for installation in areas with high seismic activity. One of the key advantages of ductile iron pipes is their ability to withstand external loads and ground movement, making them ideal for seismic zones. Ductile iron pipes have excellent flexibility and high tensile strength, allowing them to withstand ground shifting and seismic forces without breaking or fracturing. Additionally, their high resistance to impact and stress make them less susceptible to damage during seismic events. Furthermore, ductile iron pipes have a proven track record of performance in seismic areas, as they have been successfully installed and used in earthquake-prone regions around the world for many years. They have demonstrated their ability to withstand the ground movements caused by seismic activity without compromising their structural integrity. Moreover, ductile iron pipes have the advantage of being highly durable and long-lasting, which is crucial in areas with high seismic activity where infrastructure needs to withstand frequent ground movements. Their longevity reduces the need for frequent maintenance and replacement, making them a cost-effective option in the long run. However, it is important to note that proper installation techniques and adherence to seismic design guidelines are essential to ensure the optimal performance of ductile iron pipes in high seismic areas. It is recommended to consult with experienced engineers and follow local building codes and regulations to ensure the pipes are installed correctly and can withstand the specific seismic conditions of the area. Overall, due to their flexibility, strength, durability, and proven performance, ductile iron pipes are considered suitable for installation in areas with high seismic activity.

- Q: Can ductile iron pipes be used in culvert or storm sewer applications?

- Certainly, culvert or storm sewer applications can make effective use of ductile iron pipes. Renowned for their strength, durability, and flexibility, ductile iron pipes are an excellent choice for such purposes. They possess the capability to endure heavy loads, resist corrosion, and handle high flow rates, thus establishing them as a dependable option for culverts and storm sewers. Moreover, their extended lifespan and low maintenance needs further contribute to their appropriateness in these applications. Furthermore, ductile iron pipes can be easily installed and are available in various sizes and configurations to suit the specific requirements of culvert or storm sewer projects. In summary, ductile iron pipes have been extensively employed and proven to be an efficient and long-lasting solution for culvert or storm sewer applications.

- Q: What are ductile iron pipes?

- Ductile iron pipes are a type of iron piping that possess unique properties, making them highly durable and flexible. They are made by adding small amounts of magnesium to cast iron, which transforms the brittle material into a stronger and more malleable form. Due to their high tensile strength and ability to withstand extreme conditions, ductile iron pipes are commonly used in various applications such as water and sewage systems, industrial plants, and transportation infrastructure.

- Q: How are ductile iron pipes repaired if they get damaged?

- Ductile iron pipes are repaired in a few different ways depending on the extent of the damage. Here are some common methods for repairing ductile iron pipes: 1. Spot Repair: If the damage is minimal and localized, a spot repair can be carried out. This involves cutting out the damaged section of the pipe and replacing it with a new section. The new section is typically joined to the existing pipe using mechanical couplings or flanged connections. 2. Pipe Lining: In cases where the damage is more extensive but the pipe is still structurally sound, pipe lining can be used. This involves inserting a liner into the damaged pipe, which creates a new smooth surface. The liner can be made of various materials such as epoxy or cured-in-place pipe (CIPP). This method avoids the need for excavation and replacement of the entire pipe. 3. Pipe Bursting: For severely damaged or deteriorated pipes, pipe bursting may be the best option. This process involves pulling a new pipe through the existing damaged pipe, simultaneously fracturing the old pipe and replacing it with a new one. This method is typically used when the existing pipe is beyond repair and needs complete replacement. 4. Welding and Patching: In certain cases, small leaks or cracks in ductile iron pipes can be repaired by welding or patching. Welding involves melting and fusing the metal together to seal the damaged area. Patching, on the other hand, involves applying a specialized epoxy or composite material over the damaged section to create a watertight seal. It is important to note that the repair method used will depend on factors such as the extent of the damage, accessibility to the pipe, and the expertise of the repair crew. In all cases, proper assessment, planning, and execution are crucial to ensure a successful and long-lasting repair.

- Q: What is the expected joint restraint method for ductile iron pipes?

- The expected joint restraint method for ductile iron pipes is typically mechanical joint restraints, such as gland and follower glands or wedge-action restraints, which provide a secure and reliable connection while allowing for expansion and contraction of the pipes.

- Q: What are the different coating thickness options for ductile iron pipe?

- The coating thickness options for ductile iron pipe can vary depending on the specific application and requirements. Generally, there are three common coating thickness options for ductile iron pipe: 1. Standard Thickness: The standard coating thickness for ductile iron pipe is usually between 200 and 250 microns (8-10 mils). This thickness provides adequate protection against corrosion and abrasion in most soil and water environments. 2. Increased Thickness: In some cases, where the pipe is exposed to more aggressive environments or requires a longer service life, an increased coating thickness may be necessary. This can range from 300 to 500 microns (12-20 mils) or even more, depending on the specific requirements. 3. Specialized Coatings: For particularly demanding applications, specialized coatings may be used. These coatings can provide even higher levels of protection against corrosion, abrasion, or chemical exposure. The thickness of these specialized coatings can vary significantly depending on the specific coating material and application requirements. It is important to note that the selection of coating thickness should be based on a thorough assessment of the environmental conditions, intended service life, and any applicable industry standards or specifications. Consulting with a coating manufacturer or a corrosion specialist is recommended to determine the appropriate coating thickness for a specific ductile iron pipe application.

- Q: What are the typical bedding and backfill requirements for ductile iron pipes?

- To ensure the correct installation and long-term effectiveness of ductile iron pipes, it is important to adhere to the typical requirements for bedding and backfill. The bedding material should be a granular substance that provides support and evenly distributes the load on the pipe. Suitable materials include sand, gravel, or crushed stone. The bedding material should be placed uniformly and continuously along the bottom of the trench, with a minimum thickness of 6 inches. The width of the bedding layer should be at least 1.5 times the outer diameter of the pipe, or as specified by the pipe manufacturer. Once the bedding is in place, the remaining space around the pipe should be filled with backfill material. This material should also be granular and free from large stones, debris, or organic matter. It should be compacted in 6-inch increments using appropriate compaction equipment. The backfill should be evenly distributed around the pipe, ensuring there are no gaps or voids. Excessive compaction should be avoided to prevent damage or deformation of the pipe. The backfill material should extend at least 12 inches above the top of the pipe. In addition to following the bedding and backfill requirements, it is crucial to adhere to any specific guidelines provided by the pipe manufacturer. These guidelines may include recommendations for specific materials, compaction methods, or additional protective measures. Overall, proper bedding and backfilling of ductile iron pipes are essential for maintaining the structural integrity and preventing damage or failure. By following industry standards and manufacturer specifications, the pipes will perform effectively and last for a long time in various applications.

- Q: What is the typical diameter range of ductile iron pipes?

- The typical diameter range of ductile iron pipes varies depending on the specific application and industry standards. Generally, ductile iron pipes come in a wide range of diameters to accommodate various needs. In water distribution systems, the typical diameter range can vary from as small as 3 inches (76 mm) to as large as 64 inches (1626 mm) or even larger. For sewer and wastewater systems, the typical diameter range is usually between 4 inches (102 mm) to 48 inches (1219 mm). However, it is important to note that these ranges are not exhaustive and there may be instances where ductile iron pipes are available in sizes outside of these common ranges. It is always advisable to consult industry standards and specific project requirements to determine the appropriate diameter range for ductile iron pipes.

- Q: Can ductile iron pipes be used in areas with high soil erosion?

- Yes, ductile iron pipes can be used in areas with high soil erosion. Ductile iron is known for its high tensile strength and durability, making it resistant to external forces such as soil erosion. It is a suitable choice for underground piping systems in such areas, providing long-term reliability and stability.

- Q: Which is good for water polo cast iron pipe steel pipe?

- The advantage of ductile iron pipe is cheap, corrosion resistance, lack of toughness is poor, not easy to process

Send your message to us

Ductile Iron Pipe DN80-DN800 K9 EN545 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords