Ductile Iron Pipe of China DN300-DN600 EN545/EN598/ISO2531 K9 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market, such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

• accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

4).Service

• Drawing: we can translate your original drawing, offer best suggestion on design

• Quality: we have full set quality control system to guarantee the best quality.

5)Inspection

• In-house Foundry

• Third party inspection available upon requirement

6) Our goal

• To be your preferred partner

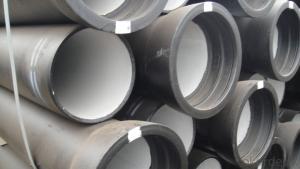

3,Ductile Iron Pipe Images:

4. Ductile Iron Pipe Specification:

Place of Origin: China (Mainland)

Model Number: DN80-1600

Length: 6M/5.7M/NEGOTIATED

Standard: ISO2531 / EN545

Application: Potable/Sewage Water

Diameter: DN80-1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: standerd

Pull Strength: 420

Yield (≥ MPa): 300

Material: Ductile Iron

water ductile iron pipe: SO2531 / EN545 DI pipe

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile

iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to

installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable

to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Can ductile iron be welded? Is weldability comparable to gray iron?

- The tensile strength of more than or equal to 70000 PSI (more than 482 n / mm2) yield strength: General 62000 (more than 427 n / mm2)Hardness (HB): 185HBWith the parent material color: similar power options: AC and DC dual-use, DC DC reverse connection

- Q: Can ductile iron pipes be used in potable water systems?

- Yes, ductile iron pipes can be used in potable water systems. Ductile iron is a type of cast iron that has enhanced strength and ductility. It is a common material choice for water infrastructure, including potable water systems, due to its durability, resistance to corrosion, and long service life. Ductile iron pipes are manufactured to meet specific standards and regulations for potable water usage, ensuring that they are safe for transporting drinking water. Additionally, ductile iron pipes have excellent flow characteristics, making them suitable for water distribution systems. Overall, ductile iron pipes are a reliable and commonly used material in potable water systems.

- Q: Can ductile iron pipe be used for high-pressure gas systems?

- Ductile iron pipe is a viable option for high-pressure gas systems due to its remarkable strength and durability. Its ability to withstand high pressures makes it suitable for applications requiring such systems. It possesses outstanding mechanical properties, including high tensile strength, yield strength, and impact resistance. These properties enable it to endure the pressures associated with gas transmission. Additionally, its resistance to corrosion ensures its reliability for long-term use in high-pressure gas systems. However, to ensure optimal safety and performance, it is crucial to consider the specific requirements and regulations of the gas system and seek guidance from industry professionals for correct installation and maintenance of the ductile iron pipe.

- Q: What are the typical pressure surge protection measures for ductile iron pipe?

- To ensure the integrity and longevity of ductile iron pipe, various measures are commonly employed to protect against pressure surges. These measures encompass the following: 1. Surge tanks serve as effective tools for absorbing and mitigating the impact of pressure surges on ductile iron pipe. These tanks are typically positioned strategically at critical points in the pipeline system, such as near valves or pump stations, providing a reservoir to contain excess pressure. 2. Air release valves are indispensable components within ductile iron pipe systems, serving the purpose of releasing trapped air and preventing the formation of air pockets. These valves maintain a stable pressure within the pipe, reducing the risk of pressure surges during operation or abrupt changes in flow. 3. Pressure relief valves are designed to safeguard ductile iron pipes by releasing excessive pressure when it surpasses a predetermined threshold. These valves are usually installed at strategic locations in the pipeline system and programmed to open when the pressure exceeds a safe limit, diverting the excess pressure to safeguard the pipe from damage. 4. Surge suppressors are devices installed in ductile iron pipe systems to absorb and dissipate pressure surges. These devices function as shock absorbers, lessening the impact of pressure fluctuations and protecting the pipe from harm. Surge suppressors are particularly effective in situations where pressure surges occur frequently or are severe. 5. Ensuring an appropriate pipe wall thickness is another critical measure for pressure surge protection in ductile iron pipe. By selecting a pipe with the correct wall thickness, engineers can guarantee the pipe's ability to withstand the pressure surges it may encounter during operation. This measure helps prevent pipe failure or rupture caused by excessive pressure. It is essential to note that the specific pressure surge protection measures employed for ductile iron pipe may vary depending on factors such as the application, pipe size, operating conditions, and regulatory requirements. Consulting experts in pipeline engineering and design is imperative to determine the most suitable pressure surge protection measures for a particular ductile iron pipe system.

- Q: Are ductile iron pipes resistant to acid mine drainage corrosion?

- Yes, ductile iron pipes are generally resistant to acid mine drainage corrosion. Their high durability, strength, and corrosion resistance make them suitable for transporting water in acidic environments, such as those affected by acid mine drainage.

- Q: Can ductile iron pipes be used in areas with high temperature variations?

- Ductile iron pipes are capable of being used in regions experiencing significant temperature fluctuations. These pipes possess exceptional thermal conductivity and can endure a wide range of temperature changes while maintaining their structural integrity. Their high coefficient of linear expansion enables them to adapt to temperature alterations without imposing substantial stress on the pipes. Consequently, ductile iron pipes are suitable for deployment in locales where extreme temperature variations, such as scorching summers and freezing winters, occur. Furthermore, these pipes exhibit remarkable resistance to thermal shock, enabling them to withstand abrupt temperature shifts without suffering cracks or breakages. In conclusion, ductile iron pipes are a dependable and long-lasting option for areas characterized by substantial temperature variations.

- Q: How much is the working pressure of ductile iron pipe used in water supply pipe and how is MPa determined?

- No, the work pressure is generally 0.4~1.6MPa, but the ultimate test pressure of ductile iron pipes is about 4.0MPa.

- Q: What is the difference between a cast iron pipe and a ductile iron pipe?

- The ball compressive strength of ductile iron pipe is much higher than that of cast iron pipes, buried in the ground, the car is not easy to be crushed.

- Q: How do ductile iron pipes handle concentrated loads?

- Ductile iron pipes are designed specifically to effectively handle concentrated loads. Their unique composition and manufacturing process give them excellent strength and durability, making them highly resistant to cracking or breaking under heavy loads. One of the main features of ductile iron pipes is their high tensile strength, allowing them to withstand concentrated loads without deforming. During the production process, small amounts of magnesium are added to cast iron, transforming the brittle graphite flakes into nodular graphite. This modification greatly enhances the material's strength and ductility, enabling it to handle concentrated loads more effectively. Furthermore, ductile iron pipes have a high modulus of elasticity, meaning they can deform elastically under a load and then return to their original shape once the load is removed. This property allows the pipes to evenly distribute the concentrated load along their entire length, reducing stress concentrations and minimizing the risk of fractures or failures. Additionally, ductile iron pipes have a thick and robust wall thickness, ensuring exceptional structural integrity. This thickness enables the pipes to bear significant loads and withstand pressure variations without compromising their overall performance. In conclusion, ductile iron pipes are engineered specifically to handle concentrated loads due to their high tensile strength, elastic deformation capabilities, and thick wall thickness. These characteristics make them a reliable choice for a variety of applications, including water and wastewater systems, as they can withstand external forces without compromising their structural integrity.

- Q: How is ductile iron pipe different from other types of pipes?

- Ductile iron pipe is different from other types of pipes primarily due to its superior strength and durability. Unlike traditional cast iron pipes, which are more brittle and prone to cracking, ductile iron pipes are highly resistant to impact and can withstand higher pressure. Additionally, ductile iron pipes have the advantage of being more flexible and easier to install, making them a preferred choice for various applications such as water and sewage systems.

Send your message to us

Ductile Iron Pipe of China DN300-DN600 EN545/EN598/ISO2531 K9 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords