Ductile Iron Pipe DN80-DN1000 K9 EN545

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

2,Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

6. Internal Lining: Cement, conform to ISO4179

7. External coating: Zinc + Bitumen, conform to ISO8179

8. Rubber: NBR, SBR, EPDM according to ISO4633 / EN681.1

9. Note: The gaskets, bolts & nuts are supplied respectively as your special requirement

10Packing and Shipping:standard export package(carton/wooden case/pallet)

accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

11.Service:Drawing: we can translate your original drawing, offer best suggestion on design

Quality: we have full set quality control system to guarantee the best quality.

Inspection: inspect in house, all our products must be checked 3 times before packing

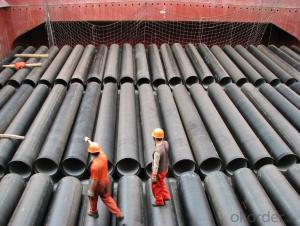

3,Ductile Iron Pipe Images:

4. Ductile Iron Pipe Specification:

Surface Finishes: Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap

End Finishes: Beveled, Square Cut, Threaded, hat

Additional Services: Internal Coating

Packaging: packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin, plastic sheeting

Test: X-ray, UT, magnetic particle,inspection,hydrostatic test.

Processing service: Beveling, Threading, Slotting, Cut-to length, Bends, Quench and Temper, Fabrication, Double-jointing and On-site assistance

Documentary: MTC, material certification,Origin certification, CI or PI,Test Report, export licence, handling order, B/L,insurance policy,shipping instructions, contract, packing list etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Can ductile iron pipes be used for underground hydrocarbon pipelines?

- Yes, ductile iron pipes can be used for underground hydrocarbon pipelines. Ductile iron is a strong and durable material that is commonly used in various applications including water and sewage systems, gas pipelines, and even hydrocarbon pipelines. Ductile iron pipes have excellent corrosion resistance properties and can withstand high pressures, making them suitable for transporting hydrocarbons underground. However, it is important to consider factors such as the specific composition of the hydrocarbons being transported and the environmental conditions of the pipeline route to ensure proper material selection and corrosion protection measures are implemented.

- Q: How much water seepage is allowed in the water pressure test for water hose DN300?

- Test method: metal composite pipe and water pipe system 10min observed in the test pressure, the pressure drop should be no more than 0.02MPa, and then reduced to working pressure check should be no leakage of plastic pipe; water supply system should be in the test pressure regulator 1H, pressure drop shall not exceed 0.05MPa, then stabilized at 1.15 times the working pressure of the state under 2h, the pressure drop shall not exceed 0.03MPa, and check each connection must not leak.

- Q: Can ductile iron pipes be used for underground compressed air systems?

- Yes, ductile iron pipes can be used for underground compressed air systems. Ductile iron pipes have high strength and durability, making them suitable for various applications including underground installations. They are corrosion-resistant, which is essential for underground systems where moisture and other environmental factors can cause damage over time. Additionally, ductile iron pipes have the ability to withstand high pressure, making them a reliable choice for compressed air systems. However, it is important to ensure that the pipes are properly installed, with proper support and protection to prevent damage or leaks. Regular maintenance and inspection should also be conducted to ensure the longevity and efficiency of the underground compressed air system.

- Q: What is the expected bedding and backfill requirements for ductile iron pipes?

- The expected bedding and backfill requirements for ductile iron pipes are vital for ensuring the longevity and proper functioning of the pipe system. Ductile iron pipes are known for their durability and strength, but they still require careful installation to prevent any potential damage or compromised performance. The bedding requirements for ductile iron pipes involve providing a stable and uniform support system to distribute the loads and stresses from the surrounding soil. The pipe should be surrounded by a bedding material that is free from rocks, debris, or any sharp objects that could potentially cause damage. The bedding material should also have sufficient compaction to prevent settlement or shifting that could lead to misalignment or pipe failure. Typically, the bedding material used for ductile iron pipes is a granular material, such as sand or fine aggregate, with a thickness of at least 6 inches. This material should be placed beneath and around the pipe in a uniform manner to provide a continuous support system. Additionally, the bedding material should be compacted to at least 90% of the maximum dry density to ensure proper stability and load distribution. Backfill requirements for ductile iron pipes involve the material used to fill the remaining space around the pipe after the bedding has been installed. The backfill material should also be free from rocks, debris, or sharp objects that could potentially damage the pipe. It should provide support and protection to the pipe while allowing for proper compaction and settling. The backfill material for ductile iron pipes is typically a granular material, such as sand or fine aggregate, with a maximum particle size of 1 inch. The backfill material should be placed and compacted in layers, ensuring that the compaction is done uniformly and evenly around the pipe. The compaction should be sufficient to prevent settlement or shifting of the backfill material, which could lead to pipe damage or misalignment. In summary, the expected bedding and backfill requirements for ductile iron pipes involve using a granular material that is free from rocks, debris, or sharp objects. The material should be placed and compacted in a uniform manner to provide stable support and protection to the pipe. Adhering to these requirements will help ensure the proper functioning and longevity of ductile iron pipe systems.

- Q: Are ductile iron pipes suitable for acidic or alkaline environments?

- Ductile iron pipes can be used in both acidic and alkaline environments, but their performance may vary depending on the conditions. Ductile iron is a type of cast iron that has been strengthened and made more flexible by adding a small amount of magnesium. This treatment allows the pipes to withstand various conditions, including those found in acidic or alkaline environments. In acidic environments, ductile iron pipes resist corrosion well. The iron in the pipes reacts with the acid to create a protective layer of iron oxide, which prevents further corrosion. However, it is important to consider factors like acid concentration and temperature, as they can affect the performance of ductile iron pipes in acidic environments. In highly concentrated or extremely acidic conditions, materials like stainless steel or corrosion-resistant alloys may be more suitable. Similarly, ductile iron pipes also resist corrosion in alkaline environments. The alkaline conditions help to passivate the iron surface, forming a protective layer that prevents further corrosion. However, the specific conditions and alkali concentrations may influence the performance of ductile iron pipes in alkaline environments. In cases of very high alkalinity or extreme temperatures, materials like plastic or concrete pipes may be more appropriate. It is important to note that regular maintenance and monitoring are necessary to ensure the long-term performance of ductile iron pipes in both acidic and alkaline environments. Monitoring the pH levels and other chemical characteristics of the environment is crucial to identify any potential issues or required maintenance. Consulting experts or engineers in the field can provide valuable insights and guidance in selecting the most suitable materials for specific acidic or alkaline environments.

- Q: How does ductile iron pipe perform in areas with high water hammer?

- Ductile iron pipe performs exceptionally well in areas with high water hammer. The strength and durability of ductile iron allow it to withstand the forceful impact of water hammer without any significant damage. Water hammer refers to the sudden increase in pressure caused by the rapid change in water flow direction or velocity, often occurring when valves are closed quickly. This abrupt change in pressure can lead to significant stress on pipes, potentially causing them to rupture or fail. However, ductile iron pipes have excellent impact resistance due to their unique composition and manufacturing process. They are made from a combination of iron, carbon, and small amounts of other elements such as silicon and magnesium. The graphite nodules formed during the manufacturing process give ductile iron its superior strength and flexibility, making it less prone to cracking or breaking under pressure. In areas with high water hammer, ductile iron pipe's inherent strength and resilience allow it to absorb and dissipate the force generated by water hammer events. Its ability to withstand the sudden pressure changes helps to prevent pipe failure, minimizing the risk of leaks or bursts. Additionally, the smooth internal surface of ductile iron pipes reduces the likelihood of water hammer occurrences by minimizing turbulence and maintaining a more constant flow. This characteristic helps to mitigate the impact of water hammer on the pipe system. Overall, ductile iron pipe is an ideal choice for areas with high water hammer due to its exceptional strength, impact resistance, and ability to withstand sudden pressure changes. Its performance in such conditions ensures the longevity and reliability of the water distribution system.

- Q: What is the expected maintenance for ductile iron pipes?

- To ensure the longevity and optimal performance of ductile iron pipes, regular inspections and preventative measures are required. The first step is to conduct routine visual inspections to detect any signs of corrosion, leaks, or damage. By examining the external surface for cracks, rust, or discoloration, potential issues can be identified at an early stage. In addition, periodic cleaning of the pipes is necessary to eliminate any debris or sediment build-up that could obstruct the water flow. This can be accomplished by flushing the pipes or utilizing mechanical cleaning techniques. It is also crucial to regularly check and maintain the protective coatings on the pipes, such as linings or external paints, to prevent corrosion and maintain their structural integrity. To extend the lifespan of ductile iron pipes, a comprehensive corrosion control program should be implemented. This may involve applying corrosion inhibitors, utilizing cathodic protection systems, and periodically re-coating the pipes. Regular monitoring of water chemistry parameters, such as pH levels and chlorine content, can further prevent corrosion and prolong the pipes' lifespan. Lastly, maintaining accurate records of maintenance activities, such as inspections, cleaning, and repairs, is essential for tracking the condition of the pipes over time. This enables proactive planning for future maintenance and replacement requirements, ensuring the efficient and reliable functioning of ductile iron pipes.

- Q: What is the external coating used in ductile iron pipes?

- The external coating used in ductile iron pipes is typically made of a protective material such as zinc or asphalt. These coatings are applied to the surface of the pipe to provide corrosion resistance and protect the iron from the surrounding environment. Zinc coatings, such as hot-dip galvanizing, are commonly used due to their excellent corrosion resistance properties. Asphalt coatings, on the other hand, provide a durable and flexible barrier against corrosion and abrasion. The choice of coating depends on factors such as the intended application, environmental conditions, and the specific requirements of the project.

- Q: Are ductile iron pipes suitable for use in residential plumbing?

- Yes, ductile iron pipes are suitable for use in residential plumbing. They are known for their durability, strength, and resistance to corrosion, making them a reliable choice for plumbing systems.

- Q: How are ductile iron pipes different from cast iron pipes?

- Ductile iron pipes are different from cast iron pipes in terms of their composition and properties. Ductile iron pipes are made from a type of cast iron that has been treated with magnesium to improve its strength and flexibility. This makes ductile iron pipes more durable, impact-resistant, and less prone to cracking or breaking compared to traditional cast iron pipes. Additionally, ductile iron pipes have a higher tensile strength, allowing them to withstand higher internal and external pressures. In summary, ductile iron pipes are a more modern and advanced version of cast iron pipes, offering improved performance and longevity.

Send your message to us

Ductile Iron Pipe DN80-DN1000 K9 EN545

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords