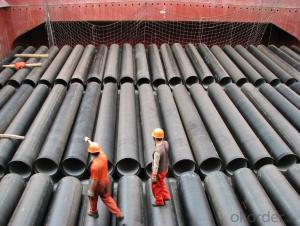

Ductile Iron Pipe DN80 DN100 DN200 K9 K8 K7

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | T type / K type / Flange type |

| Length: | 6m / 5.7m / Negotiable | Standard: | ISO2531 / EN545 / EN598 | Application: | Potable / Sewage water |

| Diameter: | DN80~DN2200 | Shape: | Round | Hardness: | 230 |

| Pipe Wall Thickness: | standard | Pull Strength: | 420 | Yield (≥ MPa): | 300 |

| Material: | Ductile Iron | Type: | Centrifugal ductile cast iron pipe | Certification: | ISO2531 / EN545 / EN598 |

| Outer Diameter: | 80-2200 | Thickness: | standard | Specification: | DN80~DN2200 |

| |

The advantages to the customer:

Trustworthy financial strength.

One-stop shopping.

Fast and efficient service.

Coordination of shipments from multiple plants.

Specialists of the overseas shipping process.

A more competitive price.

- Q: How are ductile iron pipes protected against mechanical damage?

- Ductile iron pipes are protected against mechanical damage through various measures that ensure their durability and longevity. One common method is the application of a protective coating on the exterior surface of the pipes. This coating acts as a barrier, shielding the ductile iron from physical abrasion, impact, and corrosion. The coating can be made of materials like epoxy, polyethylene, or zinc, depending on the specific requirements and environmental conditions. In addition to the protective coating, ductile iron pipes are also designed with a high level of structural strength. They are manufactured to withstand significant pressure and external forces, making them less susceptible to mechanical damage. The inherent strength of the material allows the pipes to resist deformation and cracking, even under heavy loads or ground movements. Furthermore, ductile iron pipes are often installed using proper bedding and backfilling techniques. This involves placing the pipes in a carefully prepared trench, ensuring a stable foundation and minimizing the risk of external forces causing damage. The correct backfill material is then used to provide support and prevent excessive pressure on the pipes. To enhance protection against mechanical damage, ductile iron pipes are often installed with additional measures such as concrete encasement or protective sleeves. Concrete encasement involves placing a layer of concrete around the pipe, providing an extra layer of protection against external forces. Protective sleeves can also be used in areas prone to impact or where additional protection is required. Regular inspections and maintenance are crucial in ensuring the continued protection of ductile iron pipes against mechanical damage. Periodic checks for any signs of wear, corrosion, or other forms of damage allow for timely repairs or replacement, preventing further deterioration. Overall, a combination of protective coatings, structural strength, proper installation techniques, and regular maintenance helps protect ductile iron pipes against mechanical damage, ensuring their reliable performance and longevity in various applications.

- Q: Are ductile iron pipes suitable for trenchless installation methods?

- Yes, ductile iron pipes are suitable for trenchless installation methods. Ductile iron pipes are known for their strength, durability, and flexibility, making them ideal for trenchless installation methods such as horizontal directional drilling (HDD) and pipe bursting. HDD involves drilling a small pilot hole underground and then pulling the ductile iron pipe through the hole, without the need for extensive trenching. Ductile iron pipes can withstand the pulling forces exerted during this process and can be easily guided through the underground path. Pipe bursting is another trenchless method where an existing pipe is replaced by breaking it apart while simultaneously pulling a new ductile iron pipe into place. The strength and flexibility of ductile iron pipes allow them to withstand the force required to burst the existing pipe and replace it with minimal disruption to the surrounding area. In both these trenchless installation methods, ductile iron pipes offer several advantages. They have a high resistance to corrosion and can withstand high-pressure applications, making them suitable for a wide range of underground environments. Ductile iron pipes also have a long service life, reducing the need for frequent replacement and maintenance. Overall, ductile iron pipes are a reliable and suitable choice for trenchless installation methods, providing efficient and cost-effective solutions for underground pipe installations.

- Q: What are the environmental benefits of using ductile iron pipe?

- There are several environmental benefits associated with using ductile iron pipe in various applications. Firstly, ductile iron is a highly durable material that can withstand harsh environmental conditions and has a long lifespan. This means that ductile iron pipes require less frequent replacements compared to other pipe materials, reducing the need for resource-intensive manufacturing processes and minimizing the disposal of old pipes. Secondly, ductile iron pipes have excellent corrosion resistance properties, which reduces the risk of leaks and pipe failures. This not only prevents potential water contamination but also minimizes the wastage of water resources. Additionally, ductile iron is a recyclable material. At the end of its useful life, ductile iron pipes can be melted down and used to manufacture new products, reducing the demand for virgin materials and conserving natural resources. Furthermore, the manufacturing process of ductile iron pipe has improved significantly over the years, resulting in reduced energy consumption and emissions. Today, many manufacturers use energy-efficient technologies and practices to produce ductile iron pipes, contributing to a lower carbon footprint and reduced air pollution. Lastly, ductile iron pipes have a smooth internal surface that minimizes friction and allows for efficient water flow. This can lead to energy savings in pumping and distribution systems, as less energy is required to transport water through the pipeline network. Overall, using ductile iron pipe can have a positive impact on the environment by reducing waste, conserving resources, minimizing pollution, and improving energy efficiency in water distribution systems.

- Q: Does the cast iron pipe need separate corrosion protection?

- The pipe has been antirust in the production process and can be used directly

- Q: Do ductile iron pipes require cathodic protection?

- Yes, ductile iron pipes do require cathodic protection. Cathodic protection is necessary to prevent the corrosion of ductile iron pipes, which can extend their lifespan and maintain their structural integrity. The protection is typically achieved through the use of sacrificial anodes or impressed current systems to counteract the natural corrosion process.

- Q: How is ductile iron different from cast iron?

- Ductile iron is different from cast iron in terms of its composition and mechanical properties. While both are types of iron alloys, ductile iron contains small amounts of additional elements, such as carbon, silicon, and magnesium, which enhance its strength, ductility, and impact resistance. This makes ductile iron more flexible and less brittle compared to cast iron. Additionally, ductile iron has a higher tensile strength and can withstand higher pressure and stress, making it suitable for applications where cast iron may fail.

- Q: Can ductile iron pipes be used for underground utilities?

- Yes, ductile iron pipes can be used for underground utilities. Ductile iron pipes are known for their durability, strength, and resistance to external pressure. This makes them a suitable choice for underground applications where the pipes need to withstand heavy loads, such as those found in utility installations. Ductile iron pipes are also resistant to corrosion, which is important for underground environments where the pipes are exposed to moisture and soil conditions. Additionally, these pipes have a longer service life compared to other materials, reducing the need for frequent replacements and maintenance. Therefore, ductile iron pipes are commonly used for underground utilities such as water distribution, sewage systems, and gas pipelines.

- Q: How do ductile iron pipes handle soil erosion?

- Ductile iron pipes are renowned for their exceptional strength and durability, rendering them highly resistant to the erosion of soil. The specific engineering of the material used in these pipes ensures their ability to withstand the detrimental effects of soil erosion, thereby guaranteeing long-lasting and dependable infrastructure. The composition of ductile iron pipes comprises a blend of iron, carbon, and other alloying elements, providing the necessary strength and resilience to withstand the forces exerted by soil erosion. These pipes possess a greater tensile strength than conventional cast iron pipes, enabling them to withstand pressure without deforming or cracking. Furthermore, ductile iron pipes boast a protective layer known as cement mortar lining, which acts as a barrier between the pipe and the surrounding soil. This lining offers an additional layer of resistance against corrosion and erosion caused by the chemical composition or abrasive particles present in the soil. Consequently, ductile iron pipes remain intact and continue to function effectively, even in areas experiencing high rates of soil erosion. In terms of installation, ductile iron pipes are specifically designed to be buried underground, ensuring their robust protection from direct contact with the soil. Additionally, their jointing systems are designed to provide secure and watertight connections, minimizing the risk of soil infiltration and subsequent erosion. Overall, ductile iron pipes have a proven track record of effectively combating soil erosion due to their superior strength, protective linings, and appropriate installation techniques. They offer a reliable and long-lasting solution for water and wastewater infrastructure, even in regions prone to soil erosion.

- Q: What are the different sizes available for ductile iron pipes?

- Ductile iron pipes, also known as DI pipes, are available in a wide range of sizes to suit various applications and requirements. The sizes of ductile iron pipes typically range from DN 80 (3 inches) to DN 2600 (104 inches) in diameter, with various wall thicknesses. For smaller diameters, such as DN 80 to DN 300, ductile iron pipes are commonly available in standard lengths of 5.5 meters or 6 meters. As the diameter increases, the standard lengths may also increase, reaching up to 7 meters or even longer for larger sizes. The commonly used sizes of ductile iron pipes include DN 80, DN 100, DN 150, DN 200, DN 250, DN 300, DN 350, DN 400, DN 450, DN 500, DN 600, DN 700, DN 800, DN 900, DN 1000, DN 1200, DN 1400, DN 1600, DN 1800, DN 2000, DN 2200, DN 2400, DN 2600, and many more. It is important to note that the availability of different sizes may vary depending on the manufacturer and the specific region or country. Additionally, custom sizes can also be manufactured to meet specific project requirements. When selecting the appropriate size of ductile iron pipes, it is crucial to consider factors such as the flow rate, pressure, and intended application to ensure optimal performance and durability. Consulting with industry professionals or referring to relevant standards and guidelines can help in determining the appropriate size for a specific project.

- Q: Are ductile iron pipes suitable for use in oil refineries?

- Yes, ductile iron pipes are suitable for use in oil refineries. They have excellent corrosion resistance and high tensile strength, making them ideal for transporting various fluids and gases in harsh environments such as oil refineries. Additionally, their flexibility and durability allow for easy installation and maintenance, ensuring reliable operations in refinery facilities.

Send your message to us

Ductile Iron Pipe DN80 DN100 DN200 K9 K8 K7

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords