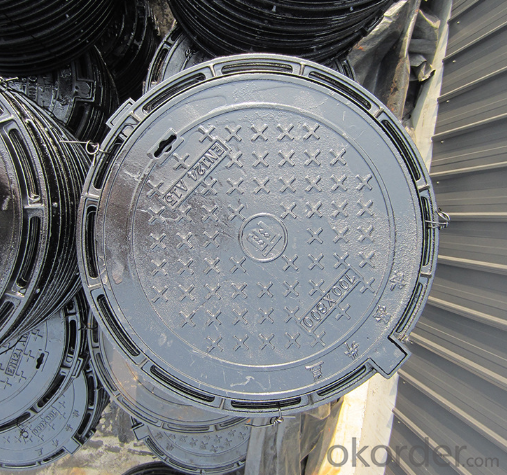

Ductile Casting Iron Manhole Cover EN124 in Handan

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4300 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

1.Place of Origin: Hebei, China (Mainland)

2.Brand Name: CMAX

3.Model Number: EN124 Standard

4.Application: Construction

5.Material: Iron

6.Dimensions: OEM

7.Surface treatment: Painting

8.Process: Casting. Drilling. Threading

9.Certification: ISO9001:2008

10.Standard: EN124 Standard

11.Name: Iron Casting Parts

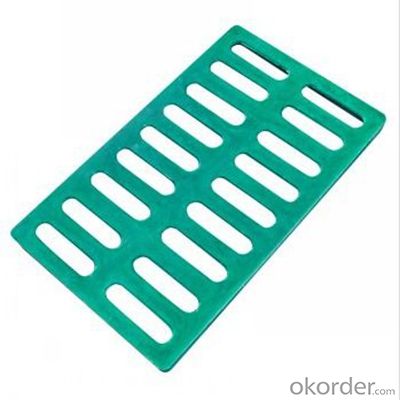

12.Color: Grey

13.Type: Moulding Press

14.Service: OEM Service

15.Size: Customer's Request

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

Advantage of ductile iron

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

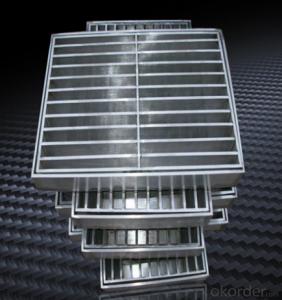

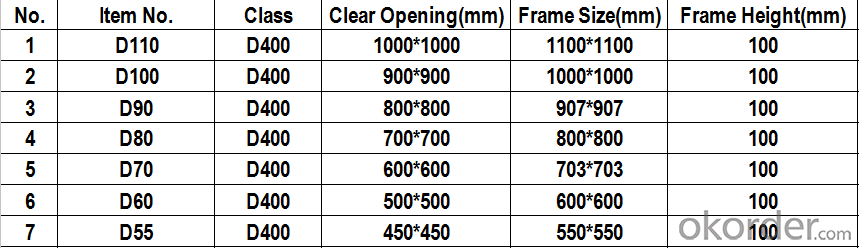

Specifications

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- As a pig iron smelting, iron smelting belongs to physical, two belongs to the chemical refining, smelting, smelting generally not as a product after use, the product can be used as a chemical composition and casting the two refining, in general is to scrap as additional material after melting making products; engine castings have professional manufacturers making castings. You can own professional production of engine castings.

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: What are the casting parts processing engineering?

- At present, casting processing, according to metal classification, divided into cast iron, cast steel, casting non-ferrous metal.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Manual coal dust, clay sand is a little worse. Mechanical styling is not bad either.

- Q: Cause of choking of casting parts

- Choke fire is the process of pouring a large number of gases can not be discharged smoothly, boiling in the metal liquid, resulting in a large number of castings in the pores, and even incomplete casting defects

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: Why should pig iron be used in casting?

- 1, in the absence of special requirements, the most important thing is that the price is cheap.2, pig iron castings quenching process requirements are not high. You can do it by hand.3, pig iron casting hardness is very large, can meet many requirements.4, pig iron castings, high temperature resistance is relatively strong. Like stoves are pig iron castings.5, pig iron casting plasticity is very bad, but in some experiments, but use this weakness to improve the sensitivity of the experiment.Wait

Send your message to us

Ductile Casting Iron Manhole Cover EN124 in Handan

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4300 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches