Drywall constuction building material China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed product description:

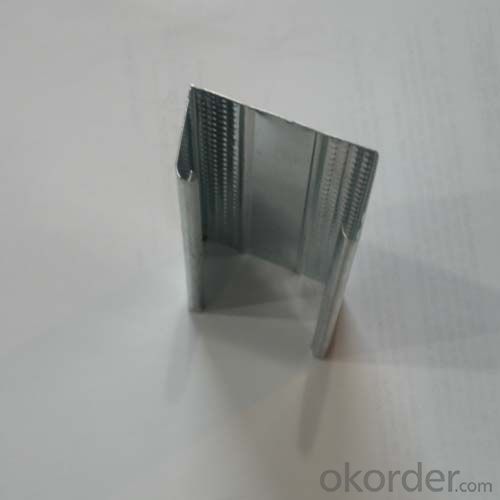

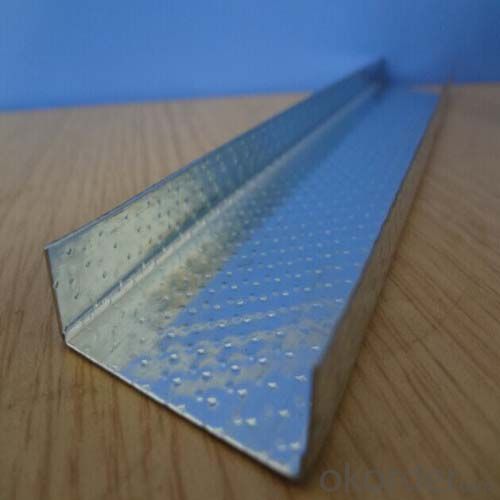

1) Item: W-35, 38 main channal, L angle, Connor Bead, DC-60, U-60, 50 Stud & track, 75 Stud and track, 100 Stud and track, ect.

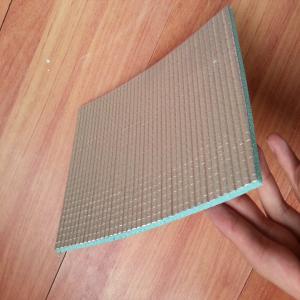

2) thickness: 0.4-1.0mm

3) Length: 3000mm or dependes on customer's request

4) Zinc coating: 50-220g/m2 (depends on the customer's request)

5) Size as fellow form: (Width*Height*Thickness)

Product apply in: Mid East , Rusia, Europ, South America, Africa

Certificate for products:CE,stand :EN13964; ISO9001-2000

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Advantages and features:

Excellent fire resistive ability. Suit residuals and public places.

Fast installation. Easy to control the construction progress

Combinative construction. Easy to keep work places clean.

Good vibration absorbing ability. Suit buildings on seismic belt.

Fast reconstruction for easy assembling and dismantling.

Filling acoustic insulation can enhance the sound-proof ability.

Surface of the walls are smooth. Easy to paint or paste wallpaper.

Electric wires are hidden in the wall

It is easy to drill through the wall for construction.

It could be applied under the original ceiling

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- Light steel keel wall moisture resistance is poor, even with glass magnesium board, Ette board and other moisture-proof sheet, but still not suitable for high water requirements of the bathroom, there will be hidden.

- Q: Light steel keel wall to remove the price

- General demolition is to ask the workers, the price of workers depends on the local price, should be the price of each place are different, hope to have a role in you.

- Q: Can my light steel keel ceiling withstand the weight?

- To be honest, the thickness of light steel is not visible, and even your different specifications are difficult to identify together. If the figure shown on the release of these things did not occur under the deformation of light steel, it should be no problem

- Q: Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- Environmental effect is obvious Light steel keel wall built-in steel components of a one-time welding and ridge installation, to avoid the construction site long-term dirty situation, in line with the social needs of energy-saving emission reduction, with significant environmental significance.

- Q: How to install light steel keel gypsum board wall

- Gypsum board installation, should be used in vertical arrangement, keel gypsum board should be wrong on both sides. Gypsum board and keel can be fixed with self-tapping screws. 12mm thick gypsum board with 25mm long self-tapping screws; two 12mm thick gypsum board with 35mm long self-tapping screws. Self-tapping screws from the edge of the gypsum board should be at least 10 mm in the board edge of the paper, at least 15 mm in the cut edge of the board. The screw cap should be buried inside the board, but no damage to the paper. Self-tapping screws from the center of the board should be 250mm, in the middle of the board should be 300mm.

- Q: Light steel keel wall Why do not cross brace welding with welding

- Then the book is too much trouble to weld, to master the master to welding, Moreover, the time is too long, so no one with the welding.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- After the installation of the gypsum board, the paper gypsum board installation and the ground to stay in the gap, so as not to drag the ground to do when the tide back. If you consider the sound effects can be filled with sound-absorbing cotton, but the effect is not good. Really too loud, you can use cotton plug The

- Q: Light steel keel partition wall construction process is what

- Light steel keel partition wall - → installation of the door hole box - → installation along the top keel and along the keel → vertical keel sub-file - → installation of vertical keel - → installation of horizontal keel card - → installation panel - Sewing practice - → face layer putty paint (or paint).

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Wood keel is best used, one is poor fire, the second is easy to produce pests, and now the ceiling are gradually replaced by light steel keel keel.

- Q: Curved gypsum board wall technology.

- The curvature of the gypsum board can not be bent directly into the required curvature; if slightly larger, you can spray a small amount of water or water bend into; and then a large curvature of the keel to be encrypted, with plaster slab splicing, and then putty leveling on the line.

Send your message to us

Drywall constuction building material China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords