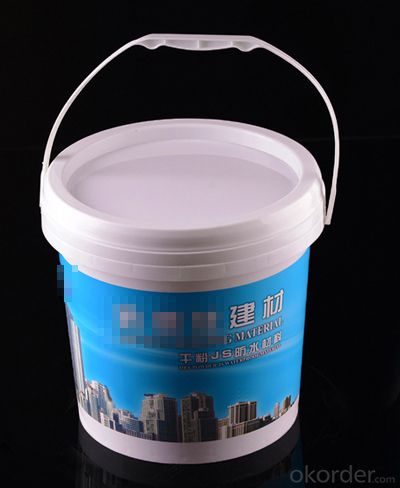

dry powder JS waterproof material New Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 3000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

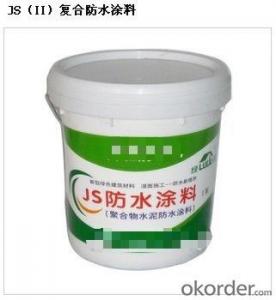

Powder JS waterproof material is a green waterproof material, the material is a composite of an organic binder and inorganic powder made of waterproof material, with a simple construction, low cost, good waterproof effect and so on.

usable range:

Based on the dry powder JS waterproof material may be wet or dry masonry, mortar, concrete, metal, wood, hard plastic, glass, gypsum board, foam board, asphalt, rubber, SBS membrane, APP membrane, polyurethane, etc. construction, industrial and civil construction of new 1st (example: houses, walls, underground, tunnels, bridges, ponds, reservoirs, bathroom, kitchen) can be used.

Directions:

* Primary surface smooth, solid, no sharp objects, dust and clear water, clean oil:

* Yang angle and pipes etc. should be made of the root of the arc-shaped, overcast corner radius greater than 25mm. Sun angle radius greater than 5mm;

* Must first leveling uneven and cracks, leaks must first plugging process.

Ingredients:

* The first increase in a barrel of water, with a mixer while stirring while slowly adding powder, stirring for 5 minutes, stirring until evenly substandard feed pellets, with a good material should be used within two hours, otherwise it will affect the viscosity increases construction;

* The amount of water added can be appropriately adjusted in order to adjust the viscosity of the material, to meet the construction facades and different parts of the plane;

* Fill in the groove seal material embedded in the yin and yang angle, root canal and other details should be many times (2-5 times) brushing, underground works should add a layer of carcass reinforcing material;

* Large-scale construction waterproof coating should be painted many times, usually three layers brushing, brushing special projects according to five layers:

* Usually each brushing time interval of 8 hours to extend the winter, every time the film thickness of 0.4-0 5mm as well, again not too thick;

* After the waterproof layer after completion of acceptance, coping finished product protection.

- Q: Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q: Eastern rainbow waterproof how to do

- General family bathroom is brush JBL waterproof coating, buy back to the first dilution, and then clean up the ground with brushing uniform brushing, the bathroom should brush the ground and the wall 1.6 meters high,

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 1, when the basement buried depth is not large, you can use the digging method, once in place, and then press the first on the next, the order of construction.

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Third, security measures 1, firmly establish the "safety first, prevention first" safety production policy. Before the operation, the site management personnel must be to the operation team to carry out security technology to the end, and actively carry out pre-class security activities, security personnel check, supervise. 2, the roof around the poles outside the scaffolding (protective railings), roof construction is strictly prohibited removal. 3, roof construction, debris and other materials is strictly prohibited from the roof directly down throwing. 4, storage of coils and adhesives warehouse or site to prohibit the fireworks, for the use of fire, there must be fire prevention measures, and should set a certain number of fire extinguishers and sand bags. 5, oil drums should be flat, not two carrying, in the transport process, pay attention to balance, the spirit to focus, to prevent accidental fall caused harm. 6, transported to the roof of the material, should be scattered on average, with the use of transport, not concentrated stacking. 7, the use of torch, you should clear the surrounding flammable items, must be away from the base of oil, is strictly prohibited in the brush base oil area using the torch. Torch petrol should not be over full, cheer should not be too much, in the fire site must be equipped with fire equipment.

- Q: What should you pay attention to before the construction of the basement waterproofing membrane?

- Plastic runway construction should pay attention to: 1, before the construction, must be on the asphalt concrete foundation for quality acceptance, acceptance criteria according to design standards and technical specifications, the plastic runway in the corresponding drainage facilities, can be used around the clock. The ambient temperature should be controlled at 5 ℃ ~ 38 ℃, to avoid below 5 ℃, 38 ℃ above the ambient temperature operation, the relative humidity control below 70%, the foundation requires a clean, according to the temperature and relative humidity to adjust the amount of catalyst The curing speed control appropriate. Color paste and prepolymer storage, the lid to be tightened, before use to detect moisture, qualified after use, the water in the foundation should also be controlled to avoid the bubble after the glue. Plastic pavement materials must be carefully checked when the quality inspection certificate and validity period.

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: Why should the use of high pressure perfusion waterproof plugging method

- Due to uneven settlement of buildings and other factors, resulting in deformation of the building structure cracking, leakage phenomenon, for the repair of this situation, you can use a new foreign plugging construction technology - high pressure grouting waterproof repair technology.

- Q: Developers have done waterproof, decoration house also have to do it

- Secondly, before the waterproof layer may be done in the house decoration, paving tiles or other equipment when the installation was destroyed, so that the waterproof layer is no longer a whole,

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Second, the completion of the construction of the membrane and the acceptance of qualified, should do the protection of finished products, it is recommended to use cement mortar to do protective layer, construction should pay attention to the surface should be smooth pressure, and set the surface sub-grid, 1 m2. If the use of block material to do the protective layer, the sub-grid area should not be greater than 100 square meters, sub-grid width should not be less than 20mm; if the use of fine stone concrete protective layer, the sub-grid area should not be greater than 36 square meters. Note: Regardless of which protective layer is used, a separation layer should be provided between the waterproofing layer and the protective layer.

- Q: Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- three, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt watering, and now have finished asphalt coating, and so on when the sunny day to deal with the basic It will not leak. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

Send your message to us

dry powder JS waterproof material New Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 3000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords