Dot 2 Geotextile for Road Construction/Landscape/Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

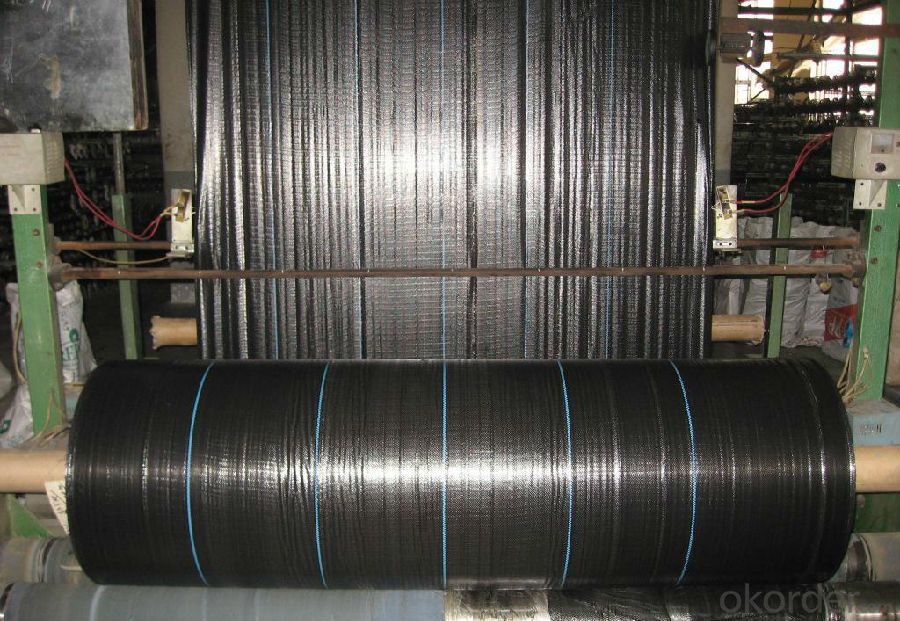

Landscape Geotextile Introduction

Landscape Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

Type: 1. Wovens & knitted: use various fibre types in different combinations.

2. Non-wovens: staple or continuous fibres that are heat treated or needlepunched to “fix” fibres relative to each other.

Landscape Geotextile Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

7) This geotextile can be made of polypropylene (PP).

8) The mass is available from 75g/m2 to 400g/m2 and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

9) Color: all kinds of color are available. The annual production ability is 10 million square meters.

10) The fabric can also be heat treated by infrared at customer's requirements. Our geotextile are UV stabilized to give protection against aging under exposure to natural ultra-violet light.

Landscape Geotextile Application

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles contribute to the stability of landfill slopes?

- Geotextiles contribute to the stability of landfill slopes by providing reinforcement and erosion control. They are placed between different layers of soil to enhance the overall strength and stability of the slope. Geotextiles help to distribute the loads more evenly, preventing excessive settlement and potential slope failure. Additionally, they reduce soil erosion by acting as a barrier against water flow, thus protecting the slope from erosion and maintaining its stability over time.

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: How do geotextiles help with pipeline protection?

- Geotextiles help with pipeline protection by acting as a barrier between the pipeline and the surrounding soil, preventing soil erosion and the formation of voids around the pipeline. They also provide additional support and reinforcement to the pipeline, reducing the risk of damage from external forces such as ground movement or heavy traffic. Furthermore, geotextiles can help with filtration, allowing water to pass through while preventing the migration of fine particles that could clog the pipeline. Overall, geotextiles enhance the longevity and structural integrity of pipelines, ensuring their safe and efficient operation.

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- When selecting geotextiles for agricultural applications, several factors need to be considered. These factors include the type and level of soil erosion, the desired drainage and filtration requirements, the expected load and stress levels on the geotextile, the potential for chemical exposure, the climate and weather conditions, and the longevity and durability needed for the specific agricultural application.

- Q: This is a large sample of gravel anti-filter how this project count

- Lack of slope and total length, can not accurately calculate the amount of engineering. Approximate estimates of cross-sectional area, then only a few simple graphics: clay tamping (rectangular), coarse gravel (trapezium), gravel and gravel (zoned plus parallel quadrilateral), geotextile (four sections)!

- Q: How do geotextiles help with erosion control?

- Geotextiles help with erosion control by providing a protective barrier against soil erosion. They are used to stabilize slopes, reinforce soil, and filter water, preventing the loss of soil particles and maintaining the integrity of the land.

- Q: What is the place of attention for the laying of geotextiles?

- (1) the use of the use of buried type: cover the thickness should not be less than 30cm (2) refurbishment system should be: cushion, impermeable layer, transition layer, protective layer composition. (3) soil to be solid, to avoid uneven subsidence, cracks, anti-seepage within the turf, root to clear. And the surface of the membrane with a small particle size of sand or clay as a protective layer. (4) laying the geomembrane do not pull too tight, both ends of the soil into the corrugated part of the soil is better, especially with the rigid material anchoring, should leave a certain amount of expansion and contraction. (5) construction, should avoid stones,

- Q: Fish pond geotextile use method

- Not geotextile to use impermeable geotextile is a filtering effect

- Q: What are the installation techniques for geotextiles?

- There are several installation techniques for geotextiles, depending on the specific application and requirements. Some common techniques include trenching, anchoring, and overlaying. Trenching involves excavating a trench and placing the geotextile in the desired location, then backfilling the trench with soil or aggregate. Anchoring involves securing the geotextile to the ground using stakes or anchors, providing stability and preventing movement. Overlaying involves placing the geotextile on top of an existing surface, such as a road or landfill, to provide reinforcement and separation. The choice of installation technique depends on factors such as soil conditions, project specifications, and desired results.

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to the soil. They are used to reinforce the soil layers, prevent erosion, and improve drainage, thereby enhancing the overall stability of the slope.

Send your message to us

Dot 2 Geotextile for Road Construction/Landscape/Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords