Dollar Tree Aluminum Foil Sheets for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

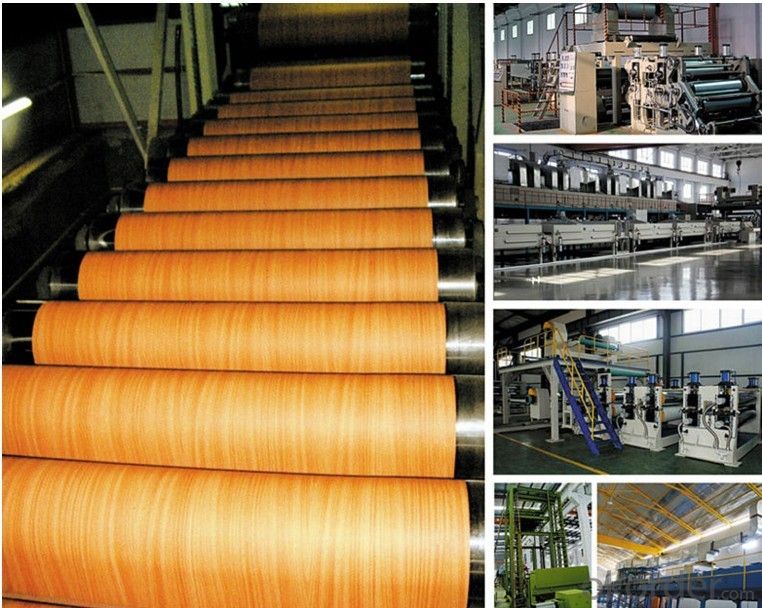

Structure of Aluminium Sheet for Construction Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Sheet for Construction Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Sheet for Construction Application:

Aluminium Sheet for Construction Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This aluminum is on a mobile home. I trying to repaint it and there is alot of areas were rust has ate the metal away. Especially in the seams. How can I get rid of the rust that already exists and stop it from coming back.

- aluminum doesn't rust but it does corrode I think they make a navel jelly for aluminum they should sell it at the hardware store just follow the directions on the bottle

- Q: How do you join aluminum sheets together?

- There are several methods to join aluminum sheets together, depending on the specific application and desired strength of the joint. Here are some common techniques: 1. Welding: Aluminum can be welded using various methods such as gas tungsten arc welding (GTAW or TIG), gas metal arc welding (GMAW or MIG), or even laser welding. These processes involve melting the aluminum at the joint and adding a filler material to create a strong bond. Welding offers excellent strength and durability but requires skill and appropriate equipment. 2. Riveting: Rivets can be used to fasten aluminum sheets together. This method involves drilling holes through the sheets and using a rivet gun to insert and deform a rivet, creating a secure joint. Riveting is relatively simple and quick, but it may not provide the same strength as welding. 3. Adhesive bonding: Industrial adhesive bonding is a popular method to join aluminum sheets. Specialized adhesives formulated for aluminum bonding are applied to the surfaces, which then cure and form a strong bond. Adhesive bonding is advantageous as it distributes stress evenly and can join dissimilar materials. However, it may not be suitable for high-temperature or high-stress applications. 4. Mechanical fasteners: Screws, bolts, or nuts can be used to fasten aluminum sheets together. This method involves drilling holes and using fasteners to secure the sheets. Mechanical fasteners provide good strength and allow for disassembly if needed. However, they may require additional maintenance and can cause stress concentrations around the holes. 5. Clinching: Clinching is a cold joining method where aluminum sheets are pressed together using a punch and die. The process deforms the materials and creates a mechanical interlock, forming a strong joint. Clinching is a quick and cost-effective method, but it may not be suitable for thin or highly rigid sheets. Ultimately, the choice of joining method depends on factors such as the required strength, aesthetics, cost, and ease of fabrication. It is recommended to consult with a qualified professional or follow specific guidelines to ensure a successful and reliable joint.

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Certainly, HVAC systems can utilize 101 aluminum sheets. Due to its exceptional thermal conductivity, resistance to corrosion, and lightweight attributes, aluminum is frequently employed in HVAC systems. The 101 aluminum alloy, a widely utilized grade, offers commendable strength and ductility, rendering it suitable for HVAC applications. It is commonly employed in the manufacturing of ducts, air handlers, heat exchangers, and various other components within HVAC systems. Moreover, aluminum sheets are highly malleable, allowing them to be easily molded and shaped in accordance with the specific demands of the HVAC system.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are suitable for signage applications. Aluminum is a lightweight and durable material, making it perfect for outdoor signs that need to withstand various weather conditions. It is resistant to rust and corrosion, which ensures the longevity of the sign. Aluminum sheets can be easily customized and cut into different shapes and sizes, allowing for versatile and creative signage options. Additionally, aluminum is a great material for digital printing and can provide high-quality graphics and images. Overall, aluminum sheets offer excellent durability, versatility, and aesthetic appeal, making them a popular choice for signage applications.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Architectural wall panels can be manufactured using aluminum sheets, which offer various benefits and are widely used in the construction industry. Aluminum is a versatile and popular material due to its many advantages. To start, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for architectural wall panels as it reduces the overall weight of the structure, simplifies transportation, and allows for greater design flexibility. In addition, aluminum provides exceptional durability and resistance to corrosion. This is crucial for wall panels as they are exposed to environmental elements such as rain, UV rays, and temperature changes. The natural oxide layer of aluminum acts as a protective barrier, ensuring the panels remain intact and maintain their appearance over time. Moreover, aluminum offers excellent thermal and acoustic insulation properties. Architectural wall panels made from aluminum can help regulate the internal temperature of buildings, resulting in energy savings and improved comfort for occupants. Furthermore, aluminum panels contribute to a quieter indoor environment by reducing noise transmission. Furthermore, aluminum can be customized in terms of shape, size, color, and finish. This allows architects and designers to create visually appealing wall panel systems that complement the overall aesthetics of a building. The versatility of aluminum sheets also enables the integration of other materials, such as glass or stone, for additional design possibilities. Lastly, aluminum is a sustainable material. It is 100% recyclable, and the energy required for recycling aluminum is significantly lower compared to the production of primary aluminum. By choosing aluminum sheets for architectural wall panels, one can promote environmentally friendly practices and contribute to the reduction of carbon emissions. In conclusion, the characteristics of aluminum, including its lightweight nature, durability, resistance to corrosion, thermal and acoustic insulation properties, design flexibility, and sustainability, make it highly suitable for manufacturing architectural wall panels.

- Q: Can aluminum sheets be used for decorative panels?

- Yes, aluminum sheets can be used for decorative panels. Aluminum is a versatile material that can be easily shaped, textured, and colored, making it suitable for various decorative applications. Its lightweight nature, durability, and resistance to corrosion also make it a popular choice for decorative panels in both indoor and outdoor settings.

- Q: Are 101 aluminum sheets suitable for outdoor applications?

- Indeed, outdoor applications can benefit from the suitability of 101 aluminum sheets. This alloy, widely favored, boasts exceptional resistance to corrosion, rendering it an optimal choice for outdoor settings frequently subjected to moisture, sunlight, and similar factors. Moreover, 101 aluminum exhibits solid strength and durability, enabling it to endure diverse weather conditions and physical strains. As a result, it finds extensive use in outdoor projects, including siding, roofing, gutters, and outdoor signage.

- Q: Can aluminum sheets be used for reflective insulation?

- Indeed, reflective insulation can make use of aluminum sheets. With their high reflectivity and impressive thermal conductivity, aluminum proves to be an exceptional option for effectively reflecting heat and minimizing heat transfer. By employing aluminum sheets as insulation, heat can be effectively redirected away from the surface, effectively preventing its entry or escape from the desired space. This proves to be advantageous in maintaining a cozy temperature indoors or safeguarding delicate equipment against extreme temperatures. Moreover, the lightweight nature and ease of installation of aluminum sheets further contribute to their popularity in reflective insulation applications.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: This question asks for guidance on selecting a trustworthy supplier for purchasing aluminum sheets.

- <p>To choose a reliable supplier of aluminum sheets, consider the following: Check their reputation by reading reviews and testimonials. Ensure they have a valid certification and adhere to industry standards. Evaluate their product quality by requesting samples or visiting their production site. Assess their delivery times and reliability. Confirm they offer competitive pricing without compromising on quality. Look for suppliers with good customer service and after-sales support. Finally, consider their financial stability and ability to fulfill large orders.</p>

Send your message to us

Dollar Tree Aluminum Foil Sheets for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords