Dollar Tree Aluminum Foil Sheets - 3003 H14 Metal Roll Aluminum Sheet 3mm Low Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

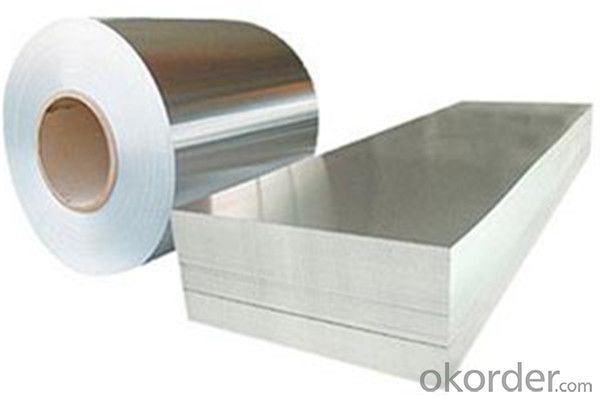

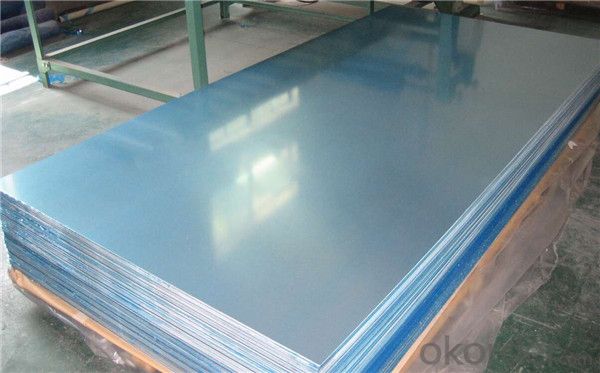

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: Can aluminum sheets be used for furniture manufacturing?

- Certainly! Furniture manufacturing can make use of aluminum sheets. Aluminum is a highly versatile material that possesses several advantageous properties, making it suitable for the production of furniture. Lightweight, durable, and corrosion-resistant, aluminum can be easily shaped into various sizes and forms. Additionally, aluminum has a sleek and modern appearance, making it a popular choice for contemporary furniture designs. Frames, legs, and other structural components for chairs, tables, shelves, and cabinets can be fashioned from aluminum sheets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, particularly for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q: Are the aluminum sheets suitable for manufacturing automotive parts?

- Yes, aluminum sheets are suitable for manufacturing automotive parts. Aluminum is a lightweight and durable material that offers several advantages for automotive applications. It has a high strength-to-weight ratio, which makes it ideal for use in manufacturing parts that require strength without adding excessive weight to the vehicle. Aluminum sheets are commonly used in the production of automotive body panels, such as hoods, doors, and fenders. Their malleability allows for easy shaping and forming, enabling manufacturers to create complex designs and intricate details. Additionally, aluminum is highly corrosion-resistant, ensuring that the automotive parts made from it will have a longer lifespan and require less maintenance. Furthermore, aluminum's excellent thermal conductivity makes it suitable for components that require heat dissipation, such as radiators and heat exchangers. Its ability to conduct electricity also makes it useful for manufacturing electrical components in vehicles. Overall, the use of aluminum sheets in automotive manufacturing offers numerous benefits. Their lightweight nature helps improve fuel efficiency, while their strength and durability ensure the structural integrity of the vehicle. Additionally, aluminum's corrosion resistance and thermal conductivity make it a reliable choice for various automotive parts.

- Q: What kind of paint would you like to paint on the aluminum plate?

- Nitro paint, polyester paint can be mainly your base, you should use atomic ash treatment before you can use, otherwise it will peel off

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a highly durable and corrosion-resistant material, making it ideal for outdoor applications. It is lightweight, yet strong enough to withstand harsh weather conditions, such as rain, snow, and UV radiation. Additionally, aluminum sheets can be coated or painted to further enhance their resistance to corrosion and provide added protection against the elements. This makes them a popular choice for outdoor structures, signage, roofing, and other exterior applications where durability and longevity are essential.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- i would start by plugging in some of those key terms into wikipedia. it often has shockingly good engineering physics articles. there are really only 4 variables: exhaust tube, annealing furnace, age hardened aluminum alloy. play with those, and you might find terms that lead you to your answer

- Q: Can aluminum sheets be embossed or engraved?

- Yes, aluminum sheets can be embossed or engraved.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean. Aluminum is a non-porous material, which means that it does not absorb liquids or stains easily. This makes it relatively easy to wipe off dirt, dust, or spills from the surface of aluminum sheets using a damp cloth or sponge. Additionally, aluminum is resistant to rust and corrosion, so it does not require any special cleaning agents or treatments. However, it is important to note that abrasive cleaners or scrubbing pads should be avoided as they can scratch the surface of the aluminum. Overall, with regular maintenance and proper cleaning techniques, aluminum sheets can be kept clean and in good condition for a long time.

- Q: What are the common thicknesses of aluminum sheets used in transportation industry?

- The common thicknesses of aluminum sheets used in the transportation industry typically range from 0.032 inches to 0.125 inches.

- Q: How do you clean aluminum sheets?

- To clean aluminum sheets, you can follow a few simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum sheet. You can use a soft brush or cloth to gently sweep away any particles. 2. Prepare a cleaning solution by mixing a mild detergent or dish soap with warm water. Avoid using strong chemicals or abrasive cleaners as they can damage the aluminum. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum sheet. Make sure to cover the entire surface, paying extra attention to any stains or spots. 4. If there are stubborn stains or marks on the aluminum, you can use a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner to a soft cloth and rub gently on the affected area until the stain is removed. 5. Rinse the aluminum sheet thoroughly with clean water to remove any soap residue. This step is essential to prevent any build-up or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Make sure there is no moisture left as it can cause water spots or corrosion over time. 7. For added shine and protection, you can apply a thin layer of aluminum polish or wax. This will help to restore the luster and protect the aluminum from future tarnish or oxidation. It is important to note that the cleaning method may vary depending on the type of dirt or oxidation on the aluminum sheet. Always read and follow the manufacturer's instructions for specific cleaning recommendations.

- Q: What unique cleaning techniques should be employed when cleaning aluminum sheets?

- <p>Yes, there are special cleaning methods for aluminum sheets. It's important to use a gentle, non-abrasive cleaner to avoid scratching the surface. Avoid using harsh chemicals or abrasive materials that can damage the aluminum. Instead, use a soft cloth or sponge with a mild detergent solution. Rinse thoroughly with water to remove any cleaning residue, as some detergents can leave a film on the aluminum. Dry the aluminum sheet immediately after rinsing to prevent water spots. Regular cleaning can help maintain the appearance and longevity of aluminum sheets.</p>

Send your message to us

Dollar Tree Aluminum Foil Sheets - 3003 H14 Metal Roll Aluminum Sheet 3mm Low Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords