Sheets of Swirl Brushed Directing Casting Aluminum Coils for Color Coating Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

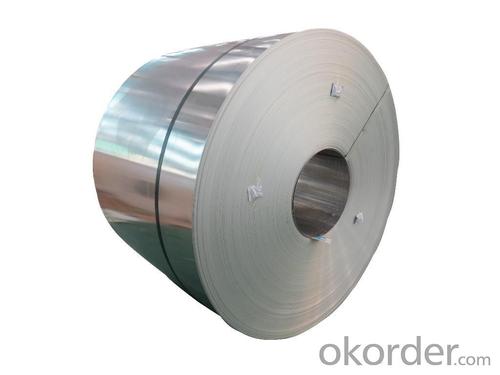

1.Structure of Directing Casting Aluminium Coils for Color Coating Rolling

Directing Casting Aluminium Coils for Color Coating Rolling is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Directing Casting Aluminium Coils for Color Coating Rolling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Directing Casting Aluminium Coils for Color Coating Rolling

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity, and it is commonly used in various electrical components and applications. Aluminum sheets are often used as conductive materials in power transmission lines, bus bars, and electrical enclosures. They are also utilized in the manufacturing of capacitors, transformers, and heat sinks due to their excellent thermal conductivity properties. Additionally, aluminum sheets are lightweight and corrosion-resistant, making them suitable for electrical applications where weight and durability are important factors.

- Q: Is it possible to use aluminum sheets as a material for exterior walls in regions with cold climates?

- <p>Yes, aluminum sheets can be used for exterior walls in cold climates. Aluminum is a durable and lightweight material with good thermal conductivity, which can be beneficial for heat transfer. However, it's crucial to use insulated aluminum panels or combine aluminum with insulation materials to prevent heat loss and maintain indoor comfort. Proper design and installation are essential to ensure the building envelope's thermal performance and structural integrity in cold weather conditions.</p>

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is currently scrap priced at eighty cents per pound. If you have enough to justify the gasoline to go to a scrap yard, yes it is worth it. Your scrap will end up in Japan rather than in a landfill.

- Q: Can the aluminum sheets be used for manufacturing automotive wheels?

- Yes, aluminum sheets can be used for manufacturing automotive wheels. Aluminum is a lightweight and durable material that is commonly used in the automotive industry due to its high strength-to-weight ratio. Aluminum sheets can be formed and machined into the desired shape and specifications required for automotive wheels. Additionally, aluminum has excellent corrosion resistance properties, which is beneficial for automotive wheels that are exposed to various weather conditions and road debris. Overall, aluminum sheets are a suitable material for manufacturing automotive wheels, providing a balance of strength, weight, and corrosion resistance.

- Q: Can the aluminum sheets be used for manufacturing aircraft engine components?

- Yes, aluminum sheets can be used for manufacturing aircraft engine components. Aluminum is a commonly used material in the aerospace industry due to its excellent strength-to-weight ratio and corrosion resistance. It is lightweight, yet strong enough to withstand the stresses and high temperatures associated with aircraft engines. Additionally, aluminum sheets can be easily fabricated, making them suitable for producing intricate engine components. Overall, aluminum sheets are a preferred choice for manufacturing aircraft engine components due to their favorable mechanical properties and suitability for aerospace applications.

- Q: why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q: This question asks for a list of various fasteners that are commonly used in the installation process of aluminum sheets.

- <p>There are several types of fasteners used for installing aluminum sheets, including: 1. Self-tapping screws, which create their own threads in the material. 2. Rivets, which join two pieces of material by compressing them together. 3. Pop rivets, a type of rivet that can be installed using a handheld tool. 4. Structural adhesives, which bond the sheets together without visible fasteners. 5. Welding, although not a fastener, it's a method used to join aluminum sheets permanently. 6. Mechanical fasteners like bolts and nuts, which are tightened to secure the sheets. 7. Clips and clamps, used for temporary or decorative installations. Each type has its own advantages and is chosen based on the specific requirements of the installation, such as load-bearing needs, aesthetic considerations, and the environment in which the aluminum sheets will be used.</p>

- Q: 1100 scope of application of aluminum plate

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment

- Q: Can aluminum sheets be used for outdoor applications?

- Yes, aluminum sheets can be used for outdoor applications. Aluminum is a durable and corrosion-resistant material, making it suitable for a wide range of outdoor uses. It is commonly used for roofing, siding, gutters, and outdoor signage. Aluminum sheets have high strength-to-weight ratio, which makes them ideal for applications where a lightweight yet sturdy material is required. Additionally, aluminum naturally forms a protective oxide layer that helps protect it from the elements, making it a reliable choice for outdoor environments.

- Q: How does aluminum sheet perform in extreme temperatures?

- Due to its unique properties, aluminum sheet exhibits exceptional performance in extreme temperatures. One of its key advantages is its remarkable thermal conductivity, enabling it to efficiently transfer heat. This characteristic allows aluminum sheet to quickly adapt to extreme temperatures, preventing the occurrence of warping or cracking that may be experienced with other materials. Moreover, aluminum possesses a high melting point of approximately 660 degrees Celsius, rendering it highly suitable for usage in high-temperature environments. It remains structurally stable, retaining its strength and integrity even when subjected to intense heat. Additionally, aluminum exhibits a low coefficient of thermal expansion, resulting in minimal expansion and contraction in response to temperature fluctuations. This particular attribute enables aluminum sheet to maintain its shape and dimensions even when exposed to drastic temperature changes. Furthermore, aluminum showcases exceptional corrosion resistance, further augmented by the formation of a natural oxide layer on its surface. This oxide layer serves as a protective barrier against chemical reactions, safeguarding the aluminum from deterioration even in harsh environments or extreme temperatures. In conclusion, aluminum sheet demonstrates outstanding performance in extreme temperatures due to its high thermal conductivity, high melting point, low coefficient of thermal expansion, and excellent corrosion resistance. These properties establish it as a reliable choice for a multitude of applications, including the aerospace, automotive, and industrial sectors, where the ability to perform under extreme temperatures is of utmost importance.

Send your message to us

Sheets of Swirl Brushed Directing Casting Aluminum Coils for Color Coating Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords