Punched Continuous Casting Aluminium Coils for Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

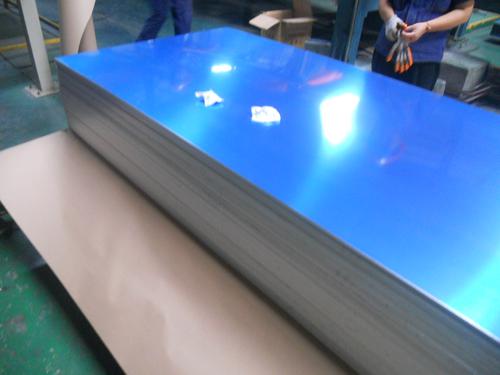

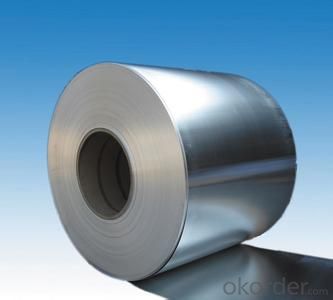

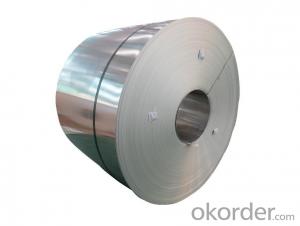

1.Structure of Continuous Casting Aluminium Coils for Rolling

Continuous Casting Aluminium Coils for Rolling is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coils for Rolling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | ROLLING | THICKNESS | WIDTH |

| AA1050 | H14 | CONTINUOUS CASTING | 0.2MM-3MM | 1000MM-1500MM |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: How do aluminum sheets perform in terms of thermal expansion?

- Aluminum sheets have a relatively high coefficient of thermal expansion, meaning they expand significantly when exposed to heat and contract when cooled. This property can be both advantageous and challenging depending on the application, as it allows for easy shaping and forming but may also cause dimensional changes and potential structural issues under extreme temperature fluctuations.

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, aluminum sheets are available in different finishes including brushed and polished. These finishes are achieved through various processes that alter the surface texture and appearance of the aluminum sheets. Brushed finishes create a textured pattern by brushing the surface with fine abrasive materials, resulting in a satin-like appearance. On the other hand, polished finishes involve buffing the surface to a high shine by using abrasive compounds or polishing wheels. These different finishes allow for customization and versatile applications of aluminum sheets in various industries.

- Q: How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- You can sprinkle the mix of Alkaline water,vinegar,washing powder and liquid detergent on the surface. And after a period of time, rub it with soft silk, after it being dry,sprinkle again and rub until it's clean.

- Q: Can aluminum sheet be used for electrical conductivity applications?

- Aluminum sheet is indeed suitable for electrical conductivity purposes. This metal possesses remarkable conductivity, ranking second only to copper. It is widely employed in electrical wiring, power transmission lines, and electrical components. Aluminum sheets find utility in various applications demanding electrical conductivity, including the creation of electrical panels, bus bars, and heat sinks. Nevertheless, it is crucial to acknowledge that the sheet's conductivity may be influenced by its thickness and purity. Hence, these aspects must be taken into account when selecting the suitable aluminum sheet for a particular electrical application.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a widely used material in the food industry due to its various beneficial properties. It is non-toxic, non-reactive, and corrosion-resistant, making it safe to use with food. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of food packaging and cooking applications. Additionally, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during cooking or baking. It is also impermeable to light, moisture, and oxygen, providing a protective barrier to maintain the freshness and quality of food. Overall, aluminum sheets are a popular choice for food contact applications due to their safety, versatility, and durability.

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- reflects heat outwards

- Q: Thickness of Aluminum Foil A rectangular sheet ofaluminum foil is 50 centimeters long and 20 centimeterswide, and weighs 5.4 grams. Find the thicknessof the aluminum foil in centimeters

- density Aluminum 2700 kg/m? Volume = 0.5 x 0.2 x d = 0.1d m? where d is thickness 5.4 g = 0.0054 kg 0.0054 kg / 2700 kg/m? = 2.0e-6 m? 2.0e-6 m? = 0.1d m? d = 2.0 e-5 m or 20 ?m or 0.02 mm or 0.002 cm .

- Q: Can aluminum sheet be used for electronic components?

- Indeed, aluminum sheet is a viable option when it comes to electronic components. This versatile material boasts numerous advantages for electronic applications. Not only is it lightweight, but it also exhibits exceptional thermal conductivity and corrosion resistance. These characteristics render it suitable for a wide range of electronic components, including heat sinks, enclosures, connectors, and printed circuit boards (PCBs). The machinability, formability, and weldability of aluminum sheets further enable efficient manufacturing processes. Moreover, aluminum proves to be a cost-effective alternative to materials like copper or steel. Nevertheless, it is crucial to acknowledge that aluminum may not be suitable for all electronic components, particularly those necessitating high electrical conductivity or magnetic shielding.

Send your message to us

Punched Continuous Casting Aluminium Coils for Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords