Fiberglass Mat Tissue Direct Roving for Filament Winding/Pultrusion/Waving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Direct Roving for Filament Winding/Pultrusion/Waving

Introduction:

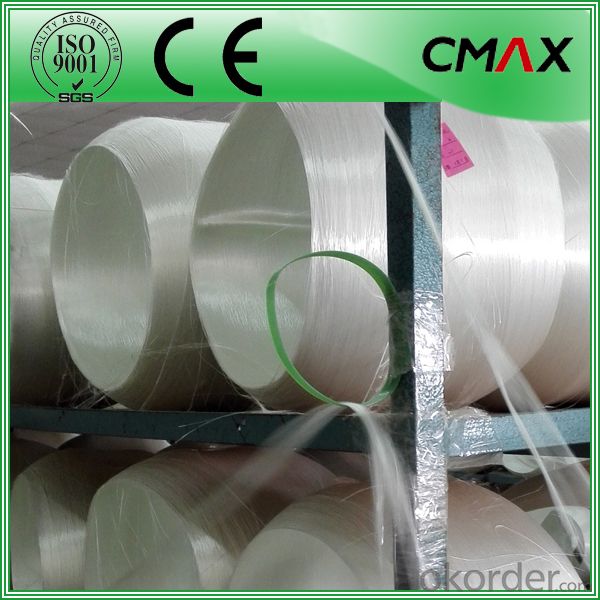

Direct Roving is coated with a silane-based sizing and compatible with unsaturated resin, vinyl resin, and epoxy resin. It is designed for filament winding, pultrusion, and weaving applications.

Direct Roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven roving converted from it is used in boats and chemical storage tanks.

Product Features:

1.Resistant to ozone, oxygen, light and climate change.

2.High strength, high modulus, low shrink, no deformation.

3.Incombustible. heat insulation, heat preservation.

4.Hgher than working temperature, still keep residual strength.

5.Corrosion resistance.

6.Electrical insulation.

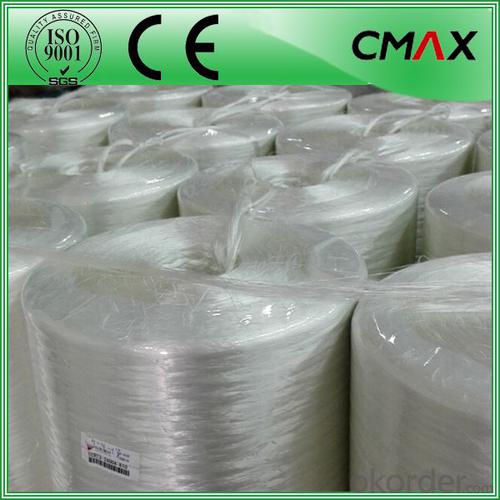

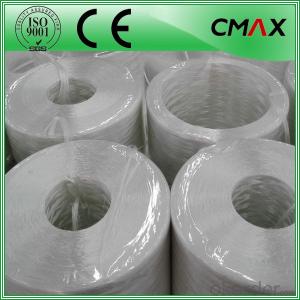

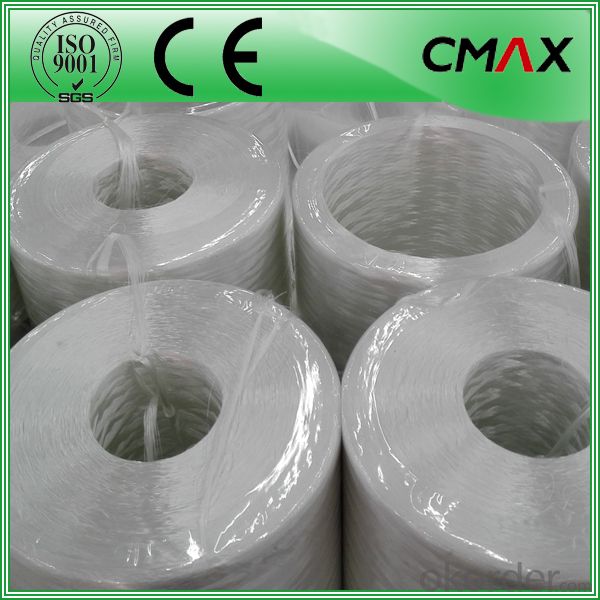

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Is fiberglass mat tissue fire-resistant?

- Fiberglass mat tissue is not naturally fire-resistant, contrary to popular belief. Although fiberglass itself is non-combustible, manufacturers usually mix the mat tissue with a flammable binder or resin. Nevertheless, there are specialized fiberglass mat tissue options that have undergone treatment with fire-resistant coatings or additives. These treated materials offer enhanced fire resistance properties and are frequently utilized in construction and insulation materials that prioritize fire safety. It is crucial to carefully examine the product specifications or seek advice from the manufacturer to ascertain the fire resistance capabilities of a specific fiberglass mat tissue.

- Q: What is the typical width of fiberglass mat tissue rolls?

- The typical width of fiberglass mat tissue rolls can vary depending on the specific manufacturer and intended application. However, in the construction and insulation industries, fiberglass mat tissue rolls are commonly available in widths ranging from 1.22 meters (4 feet) to 2.44 meters (8 feet). These dimensions are often chosen to align with standard building materials and construction practices. It is important to note that there may be variations in width options depending on the region or supplier, so it is advisable to consult with the manufacturer or supplier for the specific width requirements for a particular project.

- Q: Can fiberglass mat tissue be used for insulation in cryogenic applications?

- Indeed, insulation in cryogenic applications can be accomplished using fiberglass mat tissue. Renowned for its exceptional thermal insulation properties, fiberglass is a versatile substance. Its capability to diminish heat transfer is heightened due to its low thermal conductivity. Consequently, it is remarkably suitable for cryogenic applications that necessitate the maintenance of exceedingly low temperatures. Furthermore, fiberglass possesses non-combustible qualities and does not absorb moisture, rendering it the perfect choice for cryogenic environments. By implementing it as an insulation layer, fiberglass can effectively impede heat transfer and sustain the desired low temperatures in cryogenic storage tanks, pipes, and other related equipment.

- Q: How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue boasts exceptional moisture absorption capabilities. Its composition of fine fibers grants it a large surface area, allowing for swift moisture absorption. Moreover, fiberglass mat tissue exhibits hydrophobic properties, repelling water and preventing prolonged moisture retention. This attribute renders it an optimal material for moisture-resistant applications, including the construction of waterproofing membranes or the production of boats and water tanks. In sum, fiberglass mat tissue showcases remarkable performance in averting moisture absorption and upholding its structural integrity, even within damp surroundings.

- Q: What is the typical thickness of fiberglass mat tissue?

- The specific application and intended use determine the typical thickness of fiberglass mat tissue, which can vary. Usually, it is accessible in thicknesses ranging from 0.5mm to 3mm. The selection of thickness depends on factors like the desired strength, flexibility, and absorption properties necessary for the manufacturing of the specific project or product. Applications needing greater levels of strength and durability generally employ thicker fiberglass mat tissue, whereas thinner tissue is appropriate for lightweight and flexible applications.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Insulation boards can indeed utilize fiberglass mat tissue as a viable option. This lightweight and flexible material consists of delicate glass fibers melded together with a resin. Its outstanding thermal insulation qualities make it an optimal selection for insulation boards. The mat tissue is effortlessly customizable, capable of conforming to various shapes and sizes, thereby facilitating insulation of walls, roofs, floors, and other areas within a structure. Notably, it possesses resistance against moisture, mold, and mildew, ensuring enduring insulation performance. Moreover, fiberglass mat tissue exhibits fire-resistant properties, further bolstering its suitability for insulation applications. In summary, fiberglass mat tissue proves to be an adaptable and efficient material for insulation boards.

- Q: Can fiberglass mat tissue be used for making lightweight ceilings?

- Yes, fiberglass mat tissue can be used for making lightweight ceilings. Fiberglass mat tissue is a thin and lightweight material made from fiberglass strands that are bonded together with a binder. It is commonly used in construction and building applications due to its excellent strength-to-weight ratio. When used for making lightweight ceilings, fiberglass mat tissue can provide several advantages. Firstly, it is lightweight, which makes it easier to handle and install. This can save time and effort during construction or renovation projects. Additionally, fiberglass mat tissue is also known for its high tensile strength and durability, making it a suitable choice for ceilings that need to withstand various loads and stresses. Furthermore, fiberglass mat tissue has good thermal insulation properties, which can help in maintaining a comfortable indoor environment. It can also offer sound insulation benefits, reducing noise transmission between different spaces or floors. Moreover, fiberglass mat tissue is resistant to moisture, mold, and mildew, which makes it suitable for areas with high humidity or moisture concerns such as bathrooms or kitchens. It is also non-combustible, providing an added level of fire resistance to the ceiling structure. In conclusion, fiberglass mat tissue can indeed be used for making lightweight ceilings. Its lightweight nature, strength, durability, thermal and sound insulation properties, as well as resistance to moisture and fire, make it a suitable choice for various ceiling applications.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Yes, fiberglass mat tissue can be used for making surfboards. Fiberglass mat tissue is a lightweight and strong material that is commonly used in the construction of surfboards. It is typically layered with epoxy resin to create a durable and rigid surface. The fiberglass mat tissue provides strength and flexibility to the surfboard, allowing it to withstand the pressures and forces experienced while riding waves. Additionally, the smooth and sleek surface of the fiberglass mat tissue helps to enhance the performance and speed of the surfboard. Overall, fiberglass mat tissue is a popular choice for surfboard construction due to its excellent strength-to-weight ratio and ability to create high-performance boards.

- Q: How does fiberglass mat tissue enhance the strength of composite materials?

- Fiberglass mat tissue plays a crucial role in enhancing the strength of composite materials. It is a woven fabric made of thin fiberglass strands, which are randomly oriented and bonded together with a resin binder. This unique structure allows the fiberglass mat tissue to provide several key benefits to composite materials. Firstly, the random orientation of the fiberglass strands in the mat tissue helps distribute the stress and load more evenly across the composite material. This means that when a force is applied to the composite, the mat tissue prevents localized stress concentrations, which can lead to cracks or failure. By distributing the stress, the fiberglass mat tissue enhances the overall strength and durability of the composite material. Secondly, the resin binder used in the fiberglass mat tissue acts as a reinforcement and bonding agent. When the composite material is manufactured, the resin binder in the mat tissue infiltrates the fibers, creating a strong and cohesive structure. This not only improves the overall strength of the composite material but also enhances its resistance to impact and fatigue. Furthermore, the presence of the fiberglass strands in the mat tissue increases the stiffness of the composite material. The strands, when combined with the resin binder, create a rigid framework that adds structural integrity to the composite. This increased stiffness makes the material more resistant to deformation and improves its load-bearing capabilities. In addition to strength enhancement, fiberglass mat tissue also provides thermal and electrical insulation properties to composite materials. The fiberglass strands act as a barrier, reducing heat transfer and preventing electrical conductivity. This makes the composite material suitable for applications where insulation is required, such as in electrical enclosures or thermal insulation panels. Overall, fiberglass mat tissue plays a vital role in enhancing the strength of composite materials by distributing stress, reinforcing the structure, increasing stiffness, and providing additional insulation properties. Its random orientation, resin binder, and unique characteristics make it an indispensable component in the production of high-performance composites used in various industries, including aerospace, automotive, construction, and marine.

- Q: Is fiberglass mat tissue compatible with different types of resins?

- Yes, fiberglass mat tissue is generally compatible with different types of resins. Fiberglass mat tissue is a versatile material that can be used in conjunction with various types of resins, including polyester, epoxy, and vinyl ester resins. The compatibility between the fiberglass mat tissue and the resin depends on several factors such as the specific type and formulation of the resin, as well as the intended application of the composite material. However, in most cases, fiberglass mat tissue can be used with different types of resins to create strong and durable composite materials. It is important to carefully follow the manufacturer's recommendations and guidelines for resin selection and application to ensure optimal compatibility and performance.

Send your message to us

Fiberglass Mat Tissue Direct Roving for Filament Winding/Pultrusion/Waving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords