Fiberglass Direct Roving for Water Tanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

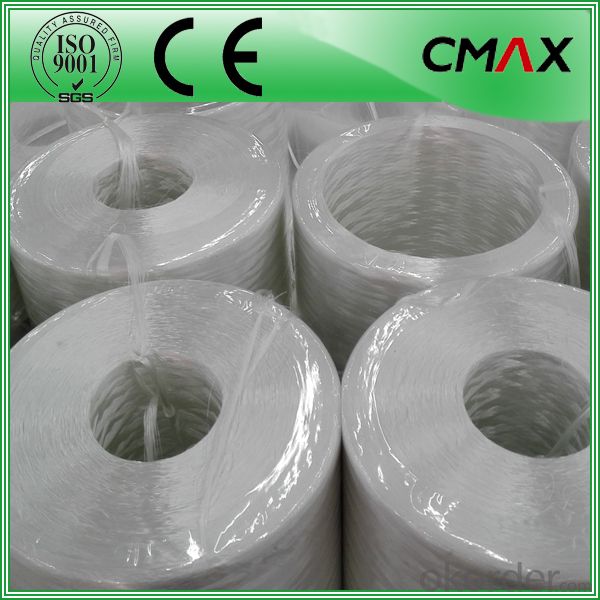

Fiberglass Direct Roving for Water Tanks

Introduction:

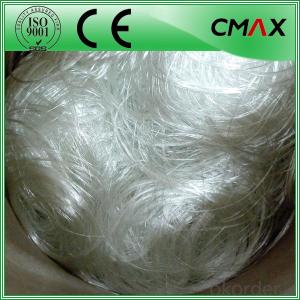

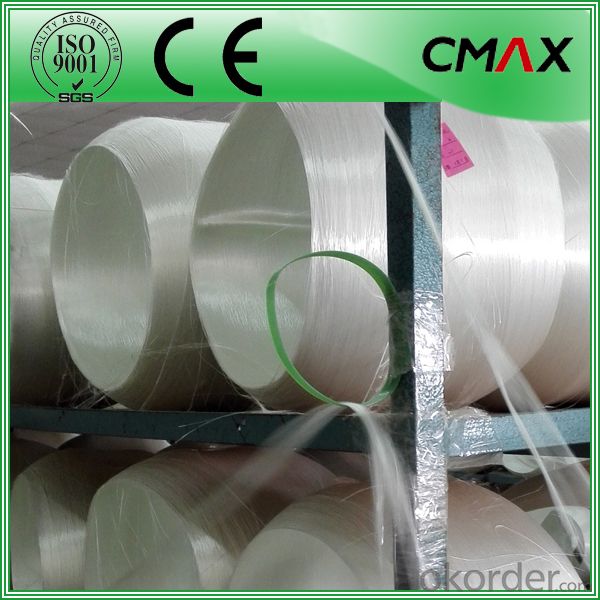

Direct Roving is coated with a silane-based sizing and compatible with unsaturated resin, vinyl resin, and epoxy resin. It is designed for filament winding, pultrusion, and weaving applications.

Direct Roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven roving converted from it is used in boats and chemical storage tanks.

Product Features:

1.Resistant to ozone, oxygen, light and climate change.

2.High strength, high modulus, low shrink, no deformation.

3.Incombustible. heat insulation, heat preservation.

4.Hgher than working temperature, still keep residual strength.

5.Corrosion resistance.

6.Electrical insulation.

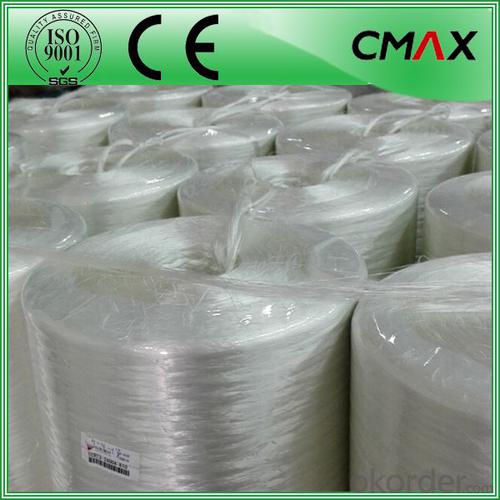

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: What are the factors that affect the diameter of electrospun nanofibers?

- High efficiency air filter, air filter (HEPA filter) is widely applied to the requirements of clean and sterile room (electronic goods and drug manufacturing sites, operation room) and other applications (such as air purifiers, vacuum bag filter and mask). Superfine glass fiber mat, melt blown (MB) fiber network, electrospun fiber mesh and ePTFE film and other media can reach...

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass tanks?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass tanks. Fiberglass mat tissue is a thin, lightweight material that is commonly used in the construction of fiberglass products. It is designed to provide additional strength and durability to the fiberglass structure. In the case of fiberglass tanks, the mat tissue can be used as a reinforcement layer to enhance the overall structural integrity of the tank. It helps to prevent cracking, improve impact resistance, and increase the tank's ability to withstand external forces and pressure. Additionally, fiberglass mat tissue is easy to work with and can be easily molded or applied to the tank's surface, making it a suitable choice for tank reinforcement.

- Q: Can fiberglass mat tissue be used for making fiberglass molds?

- Yes, fiberglass mat tissue can be used for making fiberglass molds. It is often used as a reinforcement layer to provide strength and stability to the mold, allowing it to withstand the pressures and forces exerted during the molding process.

- Q: What are the different surface finishes available for fiberglass mat tissue?

- Fiberglass mat tissue offers a variety of surface finishes, each with its own unique properties and advantages. One option is a smooth or fine finish, which gives the fiberglass mat tissue a smooth and even texture. This finish is commonly used in applications that require a high-quality surface appearance, such as cosmetic uses or when the mat will be painted or coated. Another choice is a textured or coarse finish, which adds texture and grip to the surface of the fiberglass mat tissue. This finish is often utilized in situations where increased friction or traction is necessary, like in flooring or decking materials. A third possibility is a fire-retardant finish, which provides extra fire resistance to the fiberglass mat tissue. This finish is frequently employed in applications where fire safety is a concern, such as building materials or insulation. Furthermore, there are finishes available that offer specific properties, such as enhanced chemical resistance, UV resistance, or improved durability. These finishes are commonly used in situations where the fiberglass mat tissue will be exposed to harsh environmental conditions or chemicals. Ultimately, the selection of a surface finish for fiberglass mat tissue depends on the specific application and desired properties. By choosing the appropriate finish, manufacturers can ensure that the fiberglass mat tissue meets the required performance standards and delivers the desired performance characteristics.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- Ceiling insulation requires specific materials that are more suitable and effective, such as fiberglass batts, cellulose, or foam insulation. These materials are designed to provide thermal resistance and reduce heat transfer between the interior and exterior of a building. Using fiberglass mat tissue for ceiling insulation is not recommended as it is not designed for insulation purposes. It is commonly used in construction applications like reinforcing plaster or other building materials, but it lacks the necessary thickness to effectively insulate ceilings. In addition, fiberglass insulation materials can pose safety risks as they release airborne particles and fibers that can be harmful if inhaled. Therefore, it is crucial to use insulation materials specifically engineered for ceiling insulation to ensure energy efficiency, comfort, and safety in your home or building.

- Q: Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- Yes, fiberglass mat tissue is suitable for insulation in high-rise buildings. It is commonly used as an insulating material due to its excellent thermal and sound insulation properties. Fiberglass mat tissue is lightweight, fire-resistant, and has a high melting point, making it a safe and effective choice for insulating high-rise buildings. Additionally, it is easy to install and offers good resistance against moisture and mold, ensuring long-term performance and energy efficiency.

- Q: Can fiberglass mat tissue be used for insulation purposes?

- Yes, fiberglass mat tissue can be used for insulation purposes. It is commonly used as a layer in insulation systems to provide thermal resistance and enhance the overall insulation performance.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Yes, fiberglass mat tissue may require some special tools for installation. These tools can include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment such as gloves and goggles to protect the installer from potential hazards. Additionally, some installations may require the use of a heat gun or torch to activate or cure the resin. It is important to read and follow the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used to ensure proper installation and to determine if any special tools are required.

- Q: What are the different surface textures available for fiberglass mat tissue?

- There are several different surface textures available for fiberglass mat tissue. One common texture is a smooth surface, which is often used for applications that require a sleek and polished finish. This texture is achieved by using a smooth roller or mold during the manufacturing process, resulting in a flat and even surface. Another texture option is a coarse or rough surface, which is suitable for applications that require enhanced adhesion. This texture is achieved by using a textured roller or mold during manufacturing, creating a surface with small bumps or ridges that provide increased surface area for better bonding with adhesives or coatings. A third texture option is a patterned or embossed surface, which is used for applications that require aesthetic appeal or enhanced grip. This texture is achieved by using a patterned roller or mold during manufacturing, resulting in a surface with raised or recessed designs that can be visually appealing or provide added traction when used on flooring or decking materials. Additionally, manufacturers can customize the surface texture of fiberglass mat tissue to meet specific requirements. This can include creating a textured surface with specific patterns or designs to suit individual needs or preferences. Overall, the different surface textures available for fiberglass mat tissue allow for a wide range of applications, providing options for smooth finishes, enhanced adhesion, aesthetic appeal, or improved grip.

- Q: What is the expected lifespan of fiberglass mat tissue in cleanroom applications?

- The expected lifespan of fiberglass mat tissue in cleanroom applications can vary depending on several factors such as the specific quality of the material, the level of cleanliness maintained in the cleanroom environment, and the frequency of use and maintenance. However, on average, fiberglass mat tissue in cleanroom applications can last anywhere from several months to a few years.

Send your message to us

Fiberglass Direct Roving for Water Tanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords