Direct Roving Fiberglass Roving Yarn E-Glass Fiberglass Mat Tissue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Direct Roving Fiberglass Roving Yarn E-glass

Introduction:

E-glass sprary-up roving, fiberglass gun roving, fiberglass roving is coated with a silance-based sizing, compatible with unsaturated polyester, vinyl ester and polyurethane resins.

It is a versatile general purpose spray-up roving used to manufacture boats, bathroom sinks ,yacht, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.

Product Features:

1)Silane based coupling agent which delivers most balanced sizing properties.

2)Special sizing formulation which delivers good compatibility with martix resin.

3)Consistent fiber linear density,good mold ability and dispersion

4)Excellent mechanical properties of composite products

Packaging:

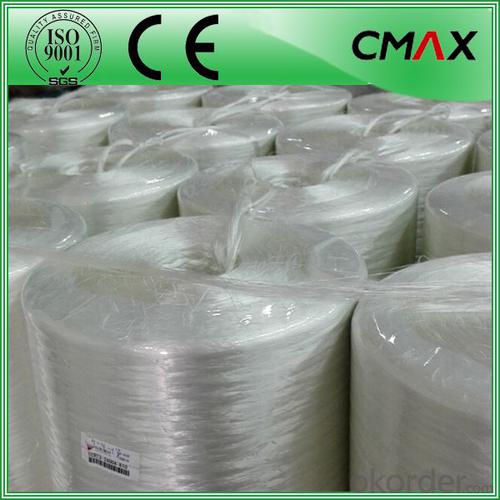

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is quite high due to its inherent properties and construction. Fiberglass mat tissue is composed of fine glass fibers that are randomly arranged and bonded together with a binder material. This arrangement creates a strong and flexible mat that can withstand impacts and external forces. The random orientation of the glass fibers allows for the distribution of stress and energy across the entire mat tissue. When an impact is applied, the fibers absorb and disperse the force, preventing it from being concentrated in one area. This property helps to minimize the risk of cracks, fractures, or failures in the material. Additionally, the binder material used in fiberglass mat tissue provides further reinforcement and cohesion to the structure. It acts as a bonding agent, keeping the glass fibers in place and enhancing their overall strength. This bonding ensures that the mat tissue remains intact and resilient even under high impact loads. Due to its excellent impact resistance, fiberglass mat tissue is commonly used in various applications where durability and strength are essential. It is often utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics (FRP), to enhance their impact resistance and structural integrity. It is also frequently employed in the construction industry for applications like roofing, wall insulation, and soundproofing, where it provides protection against impacts and external forces. Overall, the impact resistance of fiberglass mat tissue is a key characteristic that contributes to its widespread use in numerous industries. Its ability to withstand impacts and distribute forces makes it a reliable material for applications that require strength, durability, and protection against external forces.

- Q: Does fiberglass mat tissue require any special handling precautions?

- Special handling precautions are required for fiberglass mat tissue. Mishandling fiberglass mat tissue can result in the release of small glass fibers into the air. Inhalation of these fibers can lead to skin irritation, eye irritation, and respiratory problems. Therefore, it is necessary to wear appropriate protective clothing, including gloves, long-sleeved shirts, pants, and safety goggles, when dealing with fiberglass mat tissue. Working in a well-ventilated area or using respiratory protection is recommended for confined spaces. Furthermore, the material should be handled gently to prevent the release of additional fibers. Proper disposal methods must be followed to avoid any potential harm. By following these precautions, the safety and well-being of individuals handling fiberglass mat tissue are ensured.

- Q: Can fiberglass mat tissue be used for HVAC ducting?

- HVAC ducting can indeed utilize fiberglass mat tissue. This lightweight substance is formed by bonding glass fibers with resin. Its exceptional thermal insulation qualities render it suitable for HVAC systems that prioritize temperature control. Moreover, fiberglass mat tissue boasts resistance against moisture and chemicals, assuring long-lasting durability in ducting applications. Its installation is hassle-free, and it can be tailored to fit varied duct sizes and shapes. All in all, fiberglass mat tissue emerges as a dependable and effective option for HVAC ducting.

- Q: What are the main applications of fiberglass mat tissue?

- The main applications of fiberglass mat tissue include reinforcement in the construction industry for roofing, walls, and flooring, as well as insulation in thermal and acoustic systems. It is also used in the manufacturing of automotive parts, boats, and pipes for their strength and durability. Additionally, it finds use in the production of printed circuit boards and as a filtration medium in air and liquid filtration systems.

- Q: Can fiberglass mat tissue be used for swimming pool construction?

- Yes, fiberglass mat tissue can be used for swimming pool construction. It is commonly used as a reinforcement material to provide strength and durability to the pool structure.

- Q: Does fiberglass mat tissue provide any mold resistance?

- Fiberglass mat tissue does not inherently provide mold resistance. However, it can contribute to mold prevention when used in conjunction with other mold-resistant materials and proper construction practices. The fiberglass mat tissue itself is not resistant to mold growth, but it can be used as a reinforcement layer in mold-resistant building materials, such as mold-resistant drywall or sheathing. These materials are designed to resist mold growth by incorporating additives or coatings that inhibit the growth of mold and mildew. Additionally, it is important to ensure proper installation and maintenance of these materials to minimize moisture buildup and create a less favorable environment for mold growth.

- Q: How does fiberglass mat tissue perform in terms of dimensional stability?

- Fiberglass mat tissue performs exceptionally well in terms of dimensional stability. Its unique composition of fine fibers and binders helps it maintain its shape and structure even under significant stress or changes in temperature and humidity. This makes it ideal for applications where dimensional stability is crucial, such as in the construction of composite materials, automotive parts, and insulation products.

- Q: What are the potential health hazards associated with working with fiberglass mat tissue?

- There are several potential health hazards that can arise from working with fiberglass mat tissue due to its nature. One major concern is the inhalation of fiberglass particles, which can lead to respiratory problems. When fiberglass is cut or handled, it releases small particles into the air that are easily breathed in. Breathing in these particles for a prolonged period can cause irritation in the throat and lungs, as well as coughing and difficulty breathing. Another health hazard associated with fiberglass mat tissue is skin irritation. The tiny fibers from the material can cause redness, itching, and rashes when they come into contact with the skin. In some cases, prolonged exposure or repeated contact with fiberglass can result in more serious skin conditions like dermatitis. Furthermore, fiberglass mat tissue can also cause irritation and damage to the eyes. If the fibers come into contact with the eyes, they can cause redness, itching, watering, and even scratches on the cornea. It is important to wear appropriate eye protection, like goggles, to prevent any potential eye injuries when working with fiberglass. To minimize these potential health hazards, it is crucial to adhere to safety guidelines and use personal protective equipment (PPE) when working with fiberglass mat tissue. This includes wearing a respirator mask to prevent inhalation of particles, using gloves and protective clothing to reduce skin contact, and wearing safety goggles to protect the eyes. Regular cleaning and good hygiene practices are also essential to minimize any potential health risks associated with fiberglass. It is important to properly clean work areas to remove loose fibers, and to thoroughly wash hands and exposed skin after working with fiberglass. Overall, although working with fiberglass mat tissue can pose potential health hazards, taking appropriate safety precautions and following safety guidelines can greatly reduce the risk of any negative health effects.

- Q: What are the different color options available for fiberglass mat tissue?

- Fiberglass mat tissue is available in various color options to suit different preferences and applications. Some of the common colors available include white, gray, black, and beige. These color options allow for versatility in design and aesthetics, enabling users to choose a color that complements their specific project requirements. The choice of color can also be influenced by factors such as UV resistance and the desired level of visibility or camouflage. Ultimately, the availability of different color options for fiberglass mat tissue provides users with flexibility and customization possibilities to achieve their desired outcome.

- Q: Can fiberglass mat tissue be used in corrosive environments?

- No, fiberglass mat tissue is not suitable for use in corrosive environments as it is not resistant to corrosion.

Send your message to us

Direct Roving Fiberglass Roving Yarn E-Glass Fiberglass Mat Tissue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords