Direct Fiberglass Rovings China Manufacture Alkali Free Texturized Fiberglass Direct Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Direct Fiberglass Rovings China Manufacture Alkali Free Texturized Fiberglass Direct Roving

Introduction:

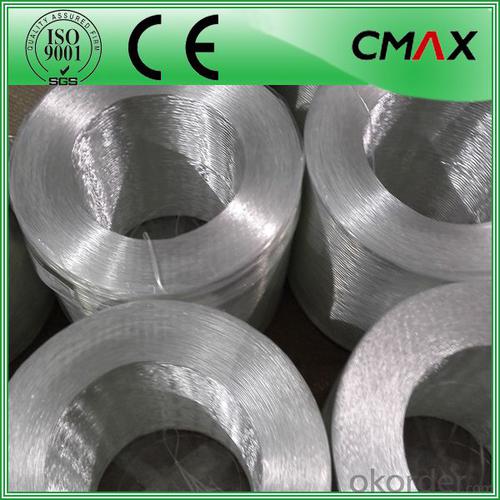

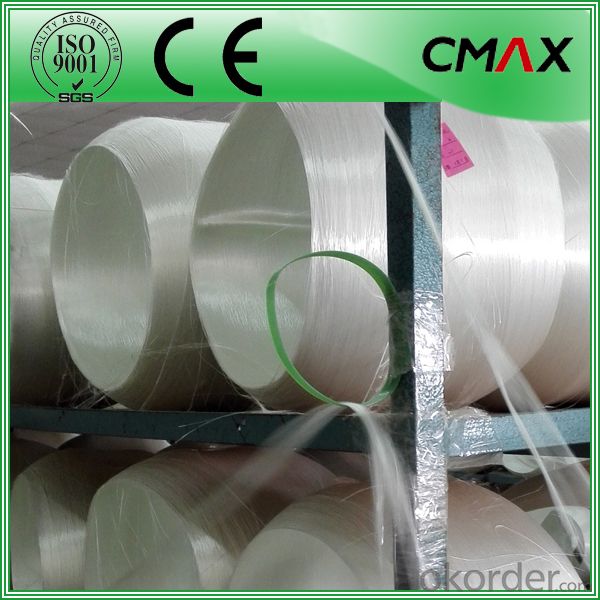

Direct Roving is coated with a silane-based sizing and compatible with unsaturated resin, vinyl resin, and epoxy resin. It is designed for filament winding, pultrusion, and weaving applications.

Direct Roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven roving converted from it is used in boats and chemical storage tanks.

Product Features:

1.Resistant to ozone, oxygen, light and climate change.

2.High strength, high modulus, low shrink, no deformation.

3.Incombustible. heat insulation, heat preservation.

4.Hgher than working temperature, still keep residual strength.

5.Corrosion resistance.

6.Electrical insulation.

Packaging:

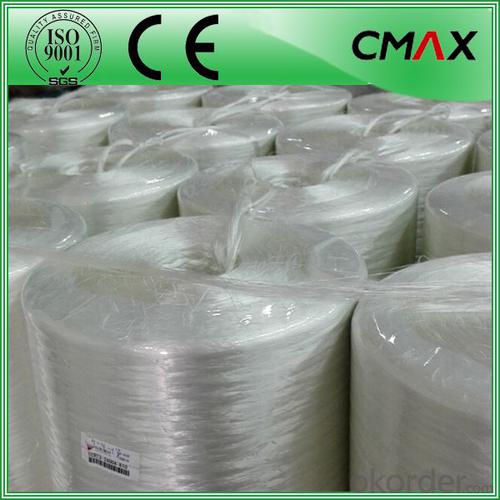

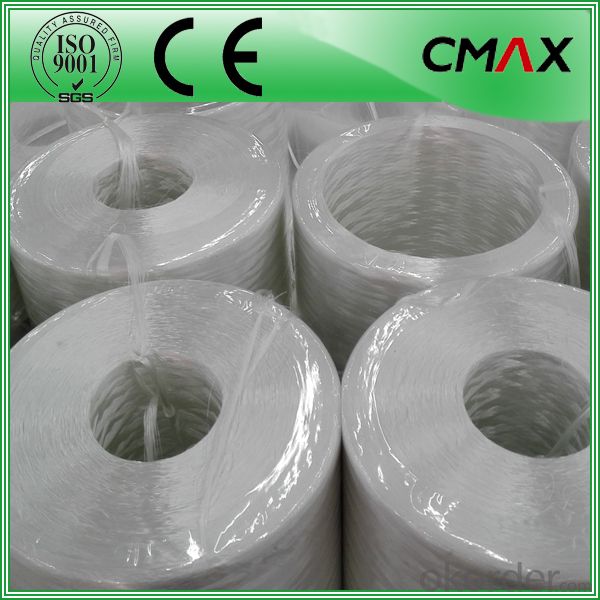

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass pools?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass pools. It helps enhance the strength and durability of the pool structure by providing added reinforcement to the fiberglass layers.

- Q: What are the typical dimensions and roll sizes of fiberglass mat tissue?

- The typical dimensions and roll sizes of fiberglass mat tissue can vary depending on the specific product and manufacturer. However, in general, fiberglass mat tissue is commonly available in rolls with widths ranging from 1 to 6 feet and lengths ranging from 100 to 1000 feet. The thickness of the tissue can range from 0.5 to 1.5 millimeters. Some manufacturers may offer custom sizes and lengths to suit specific project requirements. It is always recommended to consult the manufacturer or supplier for the exact dimensions and roll sizes of fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Yes, fiberglass mat tissue can be used for insulation boards. Fiberglass mat tissue is a lightweight, flexible material made from fine glass fibers bonded together with a resin. It has excellent thermal insulation properties, making it an ideal choice for insulation boards. The mat tissue can be easily cut to fit various shapes and sizes, and it can be used to insulate walls, roofs, floors, and other areas of a building. It is also resistant to moisture, mold, and mildew, ensuring long-lasting insulation performance. Additionally, fiberglass mat tissue is fire-resistant, further enhancing its suitability for insulation applications. Overall, fiberglass mat tissue is a versatile and effective material for insulation boards.

- Q: Does fiberglass mat tissue require any special treatment for UV resistance?

- Special treatment is required for UV resistance when using fiberglass mat tissue. This tissue is composed of fine strands of glass fibers which can be easily damaged by prolonged exposure to ultraviolet (UV) radiation. The degradation of the fibers due to UV rays can result in a reduction in strength and dimensional stability. To enhance the UV resistance of fiberglass mat tissue, manufacturers often apply a unique coating or treatment to the material. This treatment serves to safeguard the fibers from UV radiation and prevent their deterioration. The specific treatment employed may vary based on the intended application and the desired level of UV resistance. Furthermore, it is important to acknowledge that despite the special treatment, fiberglass mat tissue may still experience some degree of UV damage over time. It is therefore advised to minimize direct sunlight exposure whenever possible to ensure the longevity and performance of the material.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. It is highly resistant to corrosion and chemicals, making it an ideal choice for such environments. Additionally, fiberglass mat tissue offers excellent thermal insulation properties, helping to maintain optimal temperature levels in the plant.

- Q: What are the applications of fiberglass mat tissue?

- Fiberglass mat tissue is commonly used in various applications, including but not limited to, the construction industry, automotive manufacturing, and the production of composite materials. It is used as a reinforcement material in the construction of walls, roofs, and floors, providing strength and durability. In the automotive industry, fiberglass mat tissue is used for sound insulation and as a reinforcement material in the production of car parts. Additionally, it is widely utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics, due to its high strength-to-weight ratio and excellent corrosion resistance.

- Q: Is fiberglass mat tissue suitable for automotive panel repairs?

- Yes, fiberglass mat tissue is suitable for automotive panel repairs.

- Q: What are the different types of resins compatible with fiberglass mat tissue?

- There are several types of resins that are compatible with fiberglass mat tissue, including polyester resin, epoxy resin, and vinyl ester resin. These resins provide different properties and characteristics to the fiberglass mat, such as strength, durability, and resistance to chemicals or UV degradation. The choice of resin depends on the specific application and desired performance of the fiberglass product.

- Q: Can fiberglass mat tissue be used for making insulation panels?

- Yes, fiberglass mat tissue can be used for making insulation panels. Fiberglass mat tissue is a lightweight and flexible material that offers excellent thermal insulation properties. It is commonly used as a reinforcement layer in the production of insulation panels. The mat tissue helps to enhance the strength and durability of the panels while providing effective insulation against heat transfer. Additionally, fiberglass mat tissue is resistant to moisture, mold, and mildew, making it a suitable choice for insulation applications.

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Indeed, fiberglass canoes can be repaired using fiberglass mat tissue. This lightweight material is typically employed to reinforce fiberglass structures, and it is frequently utilized in the realm of boat repairs due to its ability to enhance strength and durability in the mended region. The mat tissue is specifically crafted to be effortlessly molded and shaped, rendering it ideal for rectifying curved surfaces like canoes. Furthermore, fiberglass mat tissue harmonizes with commonly used polyester and epoxy resins in fiberglass repairs. Consequently, it is a fitting substance for the restoration of fiberglass canoes, effectively reinstating the structural integrity of the afflicted portions.

Send your message to us

Direct Fiberglass Rovings China Manufacture Alkali Free Texturized Fiberglass Direct Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords