Direct Roving Fiberglass - C-Glass Woven Roving with Best Price and Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

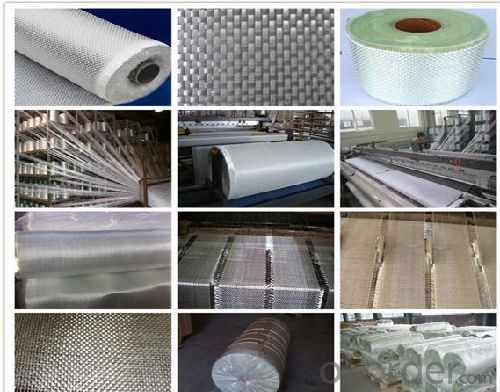

woven roving Fabric is bidirectional fabric made by 4.5 microns to 17 microns of fiber,its high strength ,high modulus ,acid and alkali resistance , high temperature resistance and other properties. often used in protection ,heat insulation ,thermal insulation ,support field . After surface treatment ,it can be made into perfect composite materials . now it is widely used in hand lay up and robot processes to manufacture boats ,vessels ,plane and automotive parts , furniture and sports facilities.

Specifications:

PRODUCT CODE | WOVEN WEIGHT (OZ/YD) | WOVEN WEIGHT (GSM) | STANDARD WIDTH (INCHES) | ROLL LENGTH (M) | THICKNESS (MM) | LOI % | Moisture Content (%) |

CT-PWR24 | 0.86 | 24 | 50 | 50M | 0.04 | ≤0.80 | ≤0.20 |

CT-PWR48 | 1.71 | 48 | 50 | 50M | 0.06 | ≤0.80 | ≤0.20 |

CT-PWR100 | 2.95 | 100 | 50 | 50M | 0.11 | ≤0.80 | ≤0.20 |

CT-PWR135 | 3.99 | 138 | 50 | 50M | 0.14 | ≤0.80 | ≤0.20 |

CT-PWR200 | 5.9 | 200 | 50 | 50M | 0.18 | ≤0.80 | ≤0.20 |

CT-PWR290 | 8.56 | 290 | 50 | 50M | 0.23 | ≤0.80 | ≤0.20 |

Main features:

1.warp and weft rovings aligned in a parallel,flat manner and uniform tension.

2.densely aligned fiber,providing high dimensional stablity and easy handing.

3.good moldability,fast and complete resin wet-out ,enabling high productivity

4.good transparency and high strength of the composite products

Remark:Woven rovings are available in the width range of 50-3000mm and the weight range of 200-1600g/m2

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: What is glass fiber?

- It has the advantages of good insulation and corrosion resistance. The diameter of monofilament is from several microns to twenty micron. It uses glass ball or waste glass as raw material and is produced by high temperature melting. Glass fibre is usually used as reinforced composite materials, but its drawback is crisp. It features with poor abrasion resistance, good heat resistance and is used as electrical insulating materials and heat/thermal insulation materials. Its diameter is equal to that of a hair. Each bundle fiber raw silk is formed by hundreds or even thousands of monofilament with high mechanical strength. Glass fiber is a kind of inorganic nonmetal material with excellent performance.

- Q: What is the technological process of glass?Fiber?chopped?strand mat?

- Fiber reinforced epoxy resin composite material forming process. Compared with traditional materials, the composite material has a series of irreplaceable characteristics, which has been developed rapidly since the second world war. Although the production is small, but the level of composite materials is one of signs that marks national or regional science, technology and economic level. Composite material is mainly composed of two parts: reinforced material and base material. Reinforced material: In composite material, some reinforced material such as the glass fiber in glass?reinforced?plastics and carbon fiber in CFRP(carbon fiber reinforced material) give major mechanical property to composite material. Matrix: Matrix is a single material which aims to make composite material as a whole such as resin in glass?reinforced?plastics( epoxy resin referred in this paper). Composite materialcan be divided into three kinds according to the matrix material: resin composite material, metal matrix composite material, and inorganic nonmetallic composite material such as ceramic matrix composite material.

- Q: How to make the lining of tank acid-proof and anticorrosion.

- If it is metal can, cleaning, descaling and brushing anticorrosion lacquer will be fine.

- Q: Glass fiber thermal insulation belt for glass fiber.

- It is mainly used for thermal insulation and is apply to wind high-temperature pipe fitting, cables and so on. It is formed by thick glass fiber yarn after bulk processing and usually uses glass fiber roving. It is widely used for electric heating wire and heating element.

- Q: Is arbon fiber better than glass fiber reinforced plastic

- Lighter and more toughness.

- Q: Definition of glass fiber reinforced plastic doors and windows

- The unsaturated resin is used as the subtrate material. it have many advantages such as sound insulation and so on. Glass?reinforced?plastics is also called glass fiber reinforced material with lightweight property. Glass?reinforced?plastics doors and windows use glass fiber twistless roving and fabric as reinforcement material. It is a new type of composite material developed abroad in early twentieth Century and can add other mineral filler.

- Q: What resin fiber powder can be used for?

- 扔掉

- Q: Epoxy resin mortar mix ratio

- 200 to 300 of mortar and 100 of epoxy resin will be fine. It should be added according to concentration. Construction convenient and high quality can be reported as the premise.

- Q: Production process of glass fiber reinforced plastic

- Technology of fiber reinforced epoxy resin composite, compared to traditional materials has a series of alternative properties since two technology are developing fastly. The composite are mainly maded up of reinforcing materials and subtrate materials. Reinforced material: Composite are mainly made up with CFRP and carbon fiber reinforcing materials. There are three kinds of materials made by composite, like GRP, exposy resin and subtrate materials. In this paper, epoxy resin composites use epoxy resin matrix, with the low curing shrinkage rate only 1%-3% and high saturated polyester resin, as high as 7%-8% and good adhesion; B phase is benefit to the production process; low curing volatile low curing stress; the performance of chemical resistance, good electrical insulation performance value ring oxygen resin solvent, alkali resistant machine performance compared with full power and phenolic acid polyester fat good; curing as a brittle, poor toughness 2 epoxy glass steel (ASTM) FW (fiber) epoxy resin and its products with steel manufacturing glass fiber enhanced

- Q: Production process of glass fiber tube

- The tube is made in continuous movement of mandrel. It should be feed into steel mould fixed in bearing. After continuous filament winding and centrifugal casting process finishes,the number of pipe manufacturers using reciprocating fiber winding process is more than that of other two production technology. After the resin in products has been solidified, you should inject unsaturated resin with catalyst at the one side of steel mould. This process is that pipe passes through a feeding station whcih aims to supply resin presoak twistless roving. There are mainly three manufacturing techniques of glass fiber pipe. Reciprocating fiber winding technology (belonging to the fixed length method). The main material includes glass fiber reinforced materials and sand. Auxiliary angle (wingding angel) is controlled by the ratio of impregnating vessel movement speed and mandrel rotate speed. Pipe usually solidifies under high temperature. With the help of centrifugal force, its applicability is very good. Continuous filament winding process(belongs to continuous method). Impregnating vessel movement is controlled by computerization machine. With the number of the layers increases gradually, inner tube form a smooth plane due to the centrifugal force and mandrel gets out of glass?reinforced?plastics pipe. Centrifugal casting process (belonging to the fixed length method). Tube made in this way, is also known as glass fiber reinforced plastic sand pipe. Reciprocating filament winding process In this process

Send your message to us

Direct Roving Fiberglass - C-Glass Woven Roving with Best Price and Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords