Description of the Hot-dip Aluzinc Steel for You

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

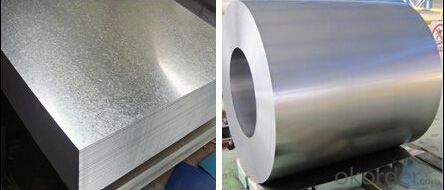

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

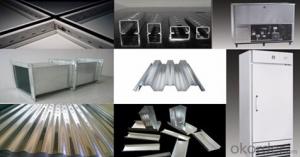

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

Available Specification

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S250GD+AZ S280GD+AZ S550GD+AZ | SGLC440 SGLC490 SGLC570 |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

3.Could you let me approach about your company in Dubai?

Located at Jebel Ali Free Zone in Dubai, CNBM Dubai Logistics Complex is adjacent to -Jebel Ali sea port-the largest port in UAE and Al Maktoum Airport-the largest airport in the world, which covers an area of 50,000 square meters, including an fully enclosed warehouse by 10,000 square meters, an open yard by 25000 square meters, and 13 standard unloading platform. CNBM Dubai Logistics Complex formally put into operation on August 1, 2013. Dubai Logistics Complex will commit itself to build the most professional and most influential building materials distribution center of China’s building materials industry in the UAE and throughout the Middle East and Africa.

- Q: What are the different types of steel coil finishing equipment?

- Various industries utilize a range of steel coil finishing equipment to ensure that steel coils are properly prepared and finished according to the desired specifications. Some commonly used equipment includes: 1. Slitting lines, which cut large steel coils into narrower strips using multiple slitting knives at high speeds. These are commonly used in automotive, construction, and packaging industries. 2. Leveling lines, which flatten and straighten steel coils with uneven surfaces or irregularities using leveling rolls and tension control systems. These are commonly used in the manufacturing of appliances, furniture, and metal roofing. 3. Recoiling lines, which rewind steel coils into smaller coils of specific diameter and weight by carefully winding them around a mandrel. These are commonly used in electrical, HVAC, and steel distribution industries. 4. Cut-to-length lines, which cut steel coils into specific lengths as per customer requirements using precision measuring systems and hydraulic shears. These are commonly used in manufacturing, construction, and fabrication industries. 5. Coating lines, which apply protective coatings or finishes on steel coils to enhance corrosion resistance, durability, and appearance. These lines typically consist of cleaning and pre-treatment sections, followed by coating application sections. They are commonly used in automotive, appliances, and construction industries. These examples represent just a few of the available types of steel coil finishing equipment. Each type serves a specific purpose and plays a crucial role in the manufacturing and processing of steel coils for various applications.

- Q: What are the main factors that affect the corrosion resistance of steel coils?

- The main factors that affect the corrosion resistance of steel coils include the composition of the steel, the presence of impurities, the surface finish, the environmental conditions, and the protective coatings applied to the steel.

- Q: What are the different methods of cutting edge trimming for steel coils?

- There are several methods of cutting edge trimming for steel coils, including shearing, slitting, laser cutting, and plasma cutting. Shearing involves using a sharp blade to cut through the coil's edge, while slitting involves using multiple circular blades to make longitudinal cuts. Laser cutting uses a high-powered laser beam to melt and vaporize the material, producing a precise and clean cut. Plasma cutting involves using a high-temperature plasma arc to melt and cut through the steel. Each method has its advantages and is chosen based on factors such as the required precision, speed, and cost-effectiveness.

- Q: What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils include surface preparation, cleanliness, and the presence of contaminants such as oil, grease, or rust. Other factors include the quality of the paint itself, the application method, and the curing process. Additionally, the type of steel and its surface condition can also influence paint adhesion.

- Q: Can steel coils be coated with fluorescent materials?

- Yes, steel coils can be coated with fluorescent materials.

- Q: Steel steps steel guard rail steel chair. You see where I'm going with this.

- The guard rails have to be steel or fans would tear them apart. The steps have to be steel..( although they are not 'solid steel'), in order to hold all that weight of people going up and down them for an entire show. The chairs are very forgiving. All in all, I can see where you are going with this, however it has been this way for decades now. Notice there are no steel tables or steel announcers desks?

- Q: What are the different surface treatments available for steel coils?

- There are various surface treatments available for steel coils, including galvanizing, painting, powder coating, and zinc coating. These treatments help protect the steel from corrosion and improve its durability and appearance.

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- Steel coils play a crucial role in the manufacturing of HVAC systems. These coils are typically made from high-quality steel, which offers exceptional strength, durability, and heat resistance. One of the main uses of steel coils in HVAC systems is for heat exchangers. Heat exchangers are vital components that facilitate the transfer of heat between two different mediums, usually air and a refrigerant. In an HVAC system, steel coils are used in both the evaporator and condenser coils. The evaporator coil absorbs heat from the air inside a building, while the condenser coil releases heat to the outside environment. These coils are designed with numerous tubes that are coiled and connected with fins. The steel construction of these coils ensures that they can withstand high-pressure environments and resist corrosion, ensuring long-term reliability and efficiency of the HVAC system. Steel coils also contribute to the overall structural integrity of HVAC systems. They are commonly used in the fabrication of ductwork, which is responsible for distributing conditioned air throughout a building. The strength and rigidity of steel coils allow ductwork to maintain its shape and structural integrity under various conditions, including high air pressure and temperature fluctuations. Furthermore, steel coils are often used in the fabrication of HVAC system cabinets and enclosures. These cabinets house various components of the system, such as compressors, fans, and control panels. The robustness of steel coils ensures that the cabinets can withstand external forces, protect the internal components, and provide a secure housing for the entire HVAC system. In summary, steel coils are essential components in the manufacturing of HVAC systems. Their strength, durability, and heat resistance make them ideal for heat exchangers, ductwork, cabinets, and enclosures. By utilizing steel coils, HVAC manufacturers can produce systems that efficiently and effectively regulate temperature, improve indoor air quality, and provide comfort in various residential, commercial, and industrial settings.

- Q: Ive been playing with my ping i3 graphite irons for 6 years now and some days i can hit it and some days i cant. Then i tried out my friends irons the other day and he had steel and i was hitting the ball anywhere i wanted it to go..Is that a fluke or is steel irons just better than shaft? I was thinking about trading my graphites for steel, is that a good idea??

- Ping Graphite Iron Shafts

- Q: What are the different types of steel coil handling devices?

- There are several types of steel coil handling devices, including coil lifters, coil grabs, coil tongs, coil hooks, and coil C-hooks. These devices are designed to safely and efficiently handle steel coils of various sizes and weights, allowing for easy transportation and storage in industrial settings.

Send your message to us

Description of the Hot-dip Aluzinc Steel for You

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords