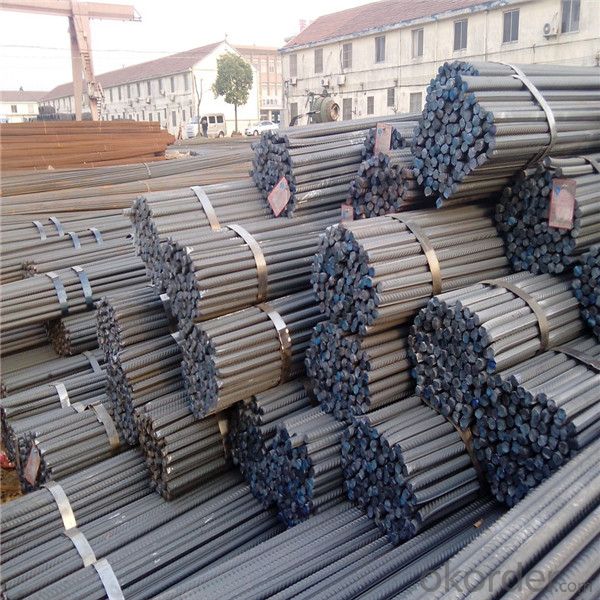

Cheap export Deformed Steel Bar for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19452 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

steel rebar is metal bars often used in construction for pouring concrete or supporting walls and columns.

The rebar can be smooth, though they are frequently manufactured with deformations that create greater

texture to which concrete can adhere, creating a stronger bond that helps prevent cracking of concrete.

These deformations do not create weaknesses in the rebar, and when rebar is measured to determine its

diameter, it is typically measured at the narrowest point.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent

over or covered with special plastic "mushroom" caps

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the different types of steel rebars used in marine constructions?

- In marine construction, several types of steel rebars are commonly used due to their specific properties and resistance to corrosion in saltwater environments. The different types of steel rebars used in marine constructions include: 1. Stainless steel rebars: Stainless steel rebars are highly resistant to corrosion, making them an ideal choice for marine applications. They contain chromium, which forms a protective oxide layer on the surface, preventing rust and corrosion. Stainless steel rebars are available in various grades, such as 304 and 316, with 316 being the most commonly used due to its higher corrosion resistance. 2. Galvanized steel rebars: Galvanized steel rebars are carbon steel rebars that have been coated with a layer of zinc. This coating acts as a barrier, protecting the steel from saltwater corrosion. Galvanized rebars are cost-effective and widely used in marine constructions. 3. Epoxy-coated steel rebars: Epoxy-coated rebars are carbon steel rebars that have been coated with an epoxy layer. This coating provides excellent protection against corrosion by acting as a barrier between the steel and the saltwater environment. Epoxy-coated rebars are commonly used in marine structures where the concrete is exposed to seawater or other corrosive agents. 4. Fiberglass rebars: Fiberglass rebars are made of high-strength glass fibers embedded in a polymer matrix. They are lightweight, non-corrosive, and have high tensile strength. Fiberglass rebars are an excellent alternative to traditional steel rebars in marine constructions, as they do not corrode in saltwater environments. 5. Titanium rebars: Titanium rebars are extremely corrosion-resistant and lightweight, making them suitable for marine applications. However, titanium rebars are more expensive than other types of steel rebars and are typically used in high-performance marine structures or specific applications where corrosion resistance is critical. Each type of steel rebar mentioned above has its own advantages and limitations, and the selection of the appropriate type depends on factors such as the project requirements, budget, and environmental conditions. It is essential for engineers and designers to consider these factors and choose the most suitable steel rebar for marine construction projects to ensure the durability and longevity of the structures.

- Q: What is the weight of a standard steel rebar?

- The weight of a standard steel rebar can vary depending on its size and length.

- Q: What is the impact of steel rebars on the overall energy efficiency of a building?

- Steel rebars have a significant impact on the overall energy efficiency of a building. As an integral part of reinforced concrete structures, rebars provide strength and stability to the building, reducing the need for excessive materials and minimizing energy consumption during construction. Additionally, steel rebars help enhance the thermal performance of a building by improving insulation, reducing heat loss, and increasing energy efficiency in heating and cooling operations. Overall, steel rebars contribute to a more sustainable and energy-efficient building design.

- Q: What factors affect the cost of steel rebars?

- The factors that affect the cost of steel rebars include the price of raw materials such as iron ore and scrap metal, the cost of production and manufacturing processes, transportation and logistics expenses, market demand and supply dynamics, currency exchange rates, and any applicable tariffs or trade policies. Additionally, economic factors such as inflation, interest rates, and overall market conditions can also impact the cost of steel rebars.

- Q: How do steel rebars affect the overall sustainability of a construction project?

- The overall sustainability of a construction project can be significantly influenced by steel rebars. To begin with, steel rebars are commonly employed to reinforce concrete structures, thereby enhancing their strength and durability. This leads to an increase in the longevity of the building, consequently minimizing the necessity for frequent repairs or replacements. As a result, the consumption of materials and energy required for maintenance over the long term is reduced. Additionally, the utilization of steel rebars contributes to the structural integrity of a construction project, enabling the design of lighter and more efficient structures. This, in turn, leads to a reduction in material usage and lower energy consumption during the construction process. Moreover, the use of steel rebars often allows for the construction of slimmer and more aesthetically pleasing structures, which can positively impact the project's environmental footprint. Moreover, steel rebars are recyclable, further enhancing the sustainability of a construction project. At the end of a building's life cycle, it is easy to recover and reuse steel rebars, thereby reducing the demand for new steel production. This not only conserves natural resources but also significantly reduces greenhouse gas emissions associated with the steel manufacturing process. Furthermore, steel rebars can contribute to the overall sustainability of a construction project by improving the building's resilience to natural disasters such as earthquakes or hurricanes. By providing additional strength and flexibility to the structure, steel rebars can help minimize damage and potentially save lives. In conclusion, the usage of steel rebars positively affects the overall sustainability of a construction project by enhancing the structural integrity and durability of buildings, reducing material and energy consumption, promoting recycling and reuse, and improving resilience to natural disasters. Their utilization is a vital component in the creation of more sustainable and environmentally friendly construction practices.

- Q: What is the effect of exposure to saltwater on steel rebars?

- Exposure to saltwater can have a detrimental effect on steel rebars, leading to corrosion and eventually weakening their structural integrity. Saltwater contains chloride ions that can penetrate the protective oxide layer on the surface of the steel, initiating a corrosion process. Over time, this corrosion can cause the rebars to rust, expand, and crack, compromising the strength and durability of the reinforced concrete structure they are embedded in. Therefore, it is essential to take preventive measures such as using corrosion-resistant coatings or stainless steel rebars to mitigate the negative effects of saltwater exposure.

- Q: Can steel rebars be used in cold weather conditions?

- Yes, steel rebars can be used in cold weather conditions. Steel is known for its durability and strength, making it a suitable material for construction projects even in cold climates. However, it is important to take certain precautions when using steel rebars in cold weather. For instance, the rebars should be properly stored and protected from moisture to prevent rusting. Additionally, the concrete mix used with the rebars should be adjusted to ensure it can withstand freezing temperatures and avoid cracking. Overall, with proper planning and precautions, steel rebars can be effectively used in cold weather conditions.

- Q: What are the guidelines for handling and disposing of steel rebars after demolition?

- To handle and dispose of steel rebars after demolition, the following guidelines should be followed: 1. Identify the steel rebars by appropriately marking or labeling them to distinguish them from other construction debris. 2. Separate the steel rebars from other waste materials on-site to ensure proper handling and recycling or disposal. 3. Take care during the demolition process to minimize damage to the steel rebars. Use suitable tools and techniques to avoid excessive bending or cutting, which can impact their recyclability. 4. Carefully remove the steel rebars from the site after demolition and transport them to the designated area for further processing or disposal. The method of removal and transportation will depend on the quantity and size of the rebars, and may involve machinery or manual labor. 5. Whenever possible, send the steel rebars to a recycling facility as they are highly recyclable. These facilities can process the rebars and convert them into new steel products, reducing the need for extracting and manufacturing new materials. 6. If recycling is not feasible, dispose of the steel rebars in accordance with local regulations. This may involve taking them to a designated landfill or waste disposal site that can handle construction materials. 7. Follow safety precautions when handling steel rebars, such as wearing appropriate personal protective equipment (PPE) like gloves and safety glasses. Additionally, use proper lifting techniques to prevent injuries. 8. Ensure compliance with local, state, and federal regulations for all handling and disposal activities. This may include obtaining necessary permits or licenses and adhering to specific waste management and recycling guidelines. By adhering to these guidelines, the handling and disposal of steel rebars after demolition can be conducted in an environmentally responsible and safe manner, contributing to sustainable construction practices.

- Q: Can steel rebars be used in structures with limited construction permits?

- No, steel rebars cannot be used in structures with limited construction permits. The use of steel rebars in construction typically requires proper permits and approvals due to safety and structural considerations.

- Q: Can steel rebars be used in structures subjected to chemical exposure?

- Steel rebars can be used in structures subjected to chemical exposure, but their suitability depends on the specific type and concentration of chemicals involved. In general, stainless steel rebars or epoxy-coated rebars are preferred for such applications as they provide better resistance to corrosion and chemical attack compared to plain carbon steel rebars. However, it is important to conduct a thorough evaluation of the chemical environment and consult with experts to determine the most appropriate rebar material for the specific structure and its intended use.

Send your message to us

Cheap export Deformed Steel Bar for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19452 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords