Deformed steel bar HRB500 400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage and Applications of HRB500 Deformed Steel Bar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of HRB500 Deformed Steel Bar:

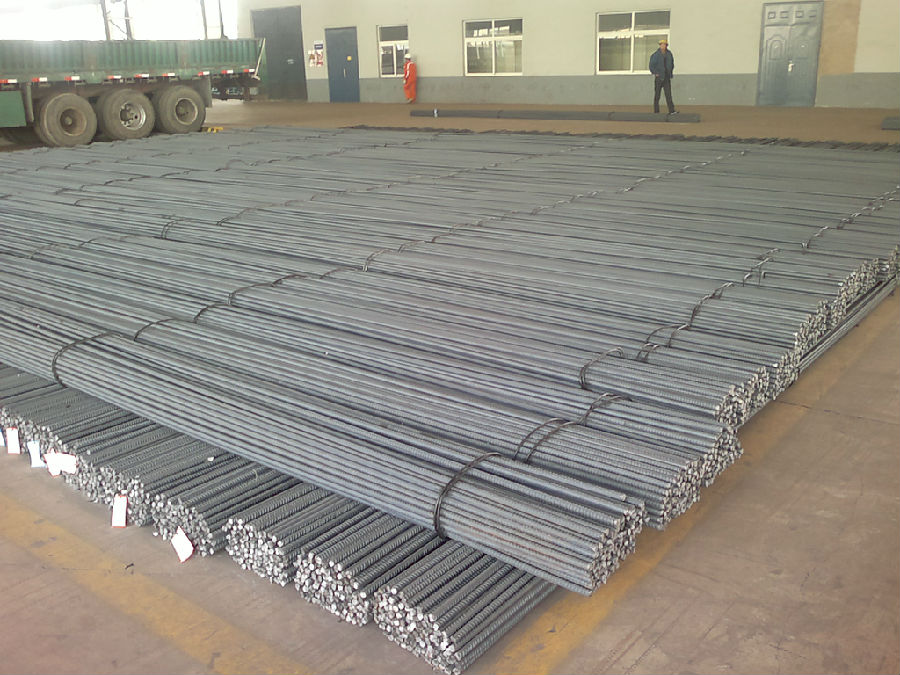

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Deformed Steel Bar in stock

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: How do steel rebars contribute to the overall stability of a structure?

- Steel rebars contribute to the overall stability of a structure by enhancing its strength and durability. These reinforcing bars are embedded within concrete to provide tensile strength, which is necessary to resist bending or cracking forces. They help distribute the applied loads evenly throughout the structure, preventing the formation of cracks and ensuring structural integrity. Additionally, rebars help prevent the structure from collapsing under extreme conditions, such as earthquakes or heavy winds, by increasing its ability to withstand these external forces.

- Q: Do l 8, three grade steel have discs?

- If small specifications or hot rolled straight line, the cost is high, not to say, production is still low, the general steel mills in order to produce the production of discoid small threads, and then according to the needs of the use of mechanical processing into a straight bar shape

- Q: What is the difference between rebar bolts and steel bars?

- Rebar is only material, and thread steel bolt is the product after the thread steel is processed.

- Q: Are steel rebars suitable for reinforcement in historical buildings?

- Yes, steel rebars are suitable for reinforcement in historical buildings. They provide strength and durability to the structure, enhancing its stability and longevity. Additionally, steel rebars can be designed and installed while minimizing visual impact, preserving the historical aesthetics of the building.

- Q: What is the minimum cover required for steel rebars in concrete structures?

- The minimum cover required for steel rebars in concrete structures typically depends on the specific design requirements and the environmental conditions. However, as a general guideline, it is commonly recommended to have a minimum cover of at least 1.5 inches (38 mm) for rebars in most concrete structures. This cover helps protect the steel from corrosion, provides fire resistance, and ensures adequate bond strength between the rebar and concrete. It is important to consult the relevant building codes, specifications, and engineering professionals to determine the precise minimum cover requirements for a specific project.

- Q: What are the weight and density of steel rebars?

- Steel rebars, also known as reinforcing bars, are commonly used in construction to provide tensile strength to concrete structures. The weight and density of steel rebars can vary depending on their size and grade. The weight of a steel rebar is determined by its cross-sectional area and the specific weight of steel, which is approximately 7850 kilograms per cubic meter (or 0.2836 pounds per cubic inch). The cross-sectional area is typically measured in square millimeters or square inches. For example, a common size of steel rebar is the #4 bar, which has a diameter of 12.7 millimeters (or 0.5 inches) and a cross-sectional area of 127 square millimeters (or 0.197 square inches). Using the specific weight of steel, we can calculate the weight of a #4 rebar as follows: Weight = Cross-sectional area x Specific weight of steel Weight = 127 mm^2 x 7850 kg/m^3 Weight = 998,950 grams or approximately 998.95 kilograms (or 2,201 pounds) In terms of density, the density of steel rebars is the same as the specific weight of steel, which is approximately 7850 kilograms per cubic meter. This density is relatively consistent across different sizes and grades of steel rebars. It is important to note that the weight and density of steel rebars can vary slightly depending on the specific composition and manufacturing process. Therefore, it is always recommended to refer to the manufacturer's specifications or consult engineering references for accurate and up-to-date information.

- Q: What are the safety measures to consider while handling steel rebars?

- To minimize the risk of accidents or injuries when working with steel rebars, it is important to consider several safety measures: 1. Personal Protective Equipment (PPE): Always wear the necessary PPE, such as safety glasses, steel-toe boots, gloves, and a hard hat. These items will protect you from potential hazards like falling rebars, sharp edges, or flying debris. 2. Proper Lifting Techniques: Use proper lifting techniques to avoid straining your back or causing injury. Bend your knees, keep your back straight, and lift with your leg muscles instead of your back. 3. Secure Storage: Store steel rebars in a secure and organized manner to prevent them from falling or rolling onto someone. Stack them stably and use support structures if needed. 4. Communication and Signage: Maintain clear communication among workers involved in rebars handling. Use hand signals or verbal cues to prevent accidents. Additionally, place safety signs or warning labels in the area to indicate potential hazards or restricted access. 5. Appropriate Tools and Equipment: Use tools and equipment specifically designed for handling steel rebars. This may include lifting clamps, rebars benders, or cutting tools. Regularly inspect and maintain these tools to ensure proper functioning. 6. Inspection and Removal of Defective Rebars: Before using steel rebars, inspect them for defects such as cracks, rust, or damage. Remove and replace any defective rebars to ensure the structural integrity. 7. Secure Work Area: Keep the work area clean and free from clutter to prevent tripping hazards and allow for easy maneuvering. Ensure sufficient lighting and remove any obstacles or potential hazards. 8. Training and Supervision: Provide proper training to workers involved in rebars handling, ensuring they are aware of safety protocols and best practices. Regularly supervise their work to identify unsafe practices and provide guidance or corrective actions. By following these safety measures, the risk of accidents and injuries when handling steel rebars can be significantly reduced, resulting in a safer work environment.

- Q: How do steel rebars prevent cracking in concrete?

- The reinforcement provided by steel rebars is essential in preventing cracking in concrete. By increasing the overall strength and durability of the structure, steel rebars counteract the tensile forces that cause concrete to crack. To create a reinforcing mesh or framework, high-strength steel rebars are strategically placed within the concrete. This mesh acts as a skeleton, effectively absorbing and distributing the tensile forces throughout the structure. As a result, cracks are prevented from forming. When external loads, such as heavy weights or seismic forces, are applied to the concrete, the rebars bear the tensile stress instead of the concrete itself. This is possible because steel rebars have a much higher tensile strength compared to concrete. By distributing stress more evenly, the rebars minimize crack formation and help maintain the concrete's structural integrity. Additionally, steel rebars improve the bond between the concrete and the reinforcement, further preventing cracks. While concrete has excellent compressive strength, its tensile strength is relatively low. The inclusion of rebars increases the overall tensile strength of the concrete, reducing the likelihood of cracking under tension. The bond between the rebars and the concrete creates a composite material that can effectively withstand both compressive and tensile forces. In summary, steel rebars play a crucial role in preventing cracking in concrete. They provide reinforcement, absorb tensile forces, and enhance the overall strength and durability of the structure. By acting as a skeleton within the concrete and distributing stress, they prevent the formation of cracks and ensure the long-lasting stability of the construction.

- Q: Can steel rebars be used for both residential and commercial constructions?

- Yes, steel rebars can be used for both residential and commercial constructions. Steel rebars are common reinforcement materials used in concrete structures to provide strength and stability. They are suitable for various construction projects, whether it is a residential house or a commercial building. The use of steel rebars ensures durability and structural integrity in both types of constructions. Additionally, steel rebars can be customized to meet specific project requirements, making them versatile and suitable for various applications in both residential and commercial construction.

- Q: What are the guidelines for repairing or replacing corroded steel rebars in existing structures?

- The guidelines for repairing or replacing corroded steel rebars in existing structures vary depending on the severity of the corrosion and the specific requirements of the project. However, there are some general guidelines that can be followed: 1. Assessment: Before proceeding with any repairs or replacements, a thorough assessment of the corrosion damage should be conducted. This may involve visual inspections, non-destructive testing, or even laboratory analysis of samples taken from the rebars. 2. Safety: Safety should always be the top priority when working with corroded rebars. Adequate precautions should be taken to ensure the safety of workers and surrounding areas. This may include the use of personal protective equipment and ensuring a stable work environment. 3. Determine the extent of corrosion: It is important to determine the extent of corrosion and whether it has affected the structural integrity of the rebars. This can help in deciding whether repair or replacement is necessary. 4. Repair methods: Depending on the severity of corrosion, various repair methods can be employed. These may include removing the corroded portion of the rebar and applying a corrosion inhibitor or protective coating, or using electrochemical techniques such as cathodic protection to prevent further corrosion. 5. Replacement: If the corrosion damage is extensive and repair is not feasible, the corroded rebars may need to be replaced. The replacement rebars should be of the same or higher grade and should be properly anchored to maintain the structural integrity of the existing structure. 6. Design considerations: When repairing or replacing corroded rebars, it is important to consider the design requirements of the structure. The repaired or replaced rebars should meet the necessary load-bearing capacity and should be properly integrated into the existing structure. 7. Quality control: Throughout the repair or replacement process, rigorous quality control measures should be implemented to ensure the effectiveness and durability of the repairs. This may include regular inspections, testing, and monitoring of the repaired or replaced rebars. It is important to note that these guidelines are general recommendations and should be tailored to the specific circumstances and requirements of each project. Therefore, it is advisable to consult with a structural engineer or a professional experienced in repairing corroded steel rebars for a more accurate and detailed guideline.

Send your message to us

Deformed steel bar HRB500 400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords