Deformed Bars Grade JIS G3112-2004 SD345

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Bars Grade JIS G3112-2004 SD345

Details of Deformed Bars Grade JIS G3112-2004 SD345

Name | Deformed Bar |

Shape | Round Bar |

Standard | 1.GB1499.2-2007, HRB335, HRB400E 2. ASTM A615 Gr.40, Gr.60 3.BS4449/1997 |

Diameter | 6mm-50mm |

Length | 6m, 8m, 9m,12m as standard or as request |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of Deformed Bars Grade JIS G3112-2004 SD345

Standard | Grade | Yield Strength Mpa | Tensile Strength | Elongation% |

BS4449:1997 | 250 | 250 | 295 | 22 |

460A | 460 | 485 | 12 | |

460B | 460 | 500 | 15 | |

GB1499.2-2007 | HRB335/335E | 335 | 455 | 17 |

HRB400/400E | 400 | 540 | 17 | |

HRB500/500E | 500 | 630 | 16 | |

ASTM A615 & A615M-04a | GRADE40 | 280 | 420 | 12 |

GRADE60 | 420 | 620 | 9 | |

GRADE75 | 520 | 690 | 7 | |

JIS G3112-2004 | SD295A | ≥ 295 | 440-600 | 17 |

SD295B | 295-390 | ≥ 440 | 17 | |

SD345 | 345-440 | ≥490 | 19 | |

SD390 | 390-510 | 560 | 17 | |

SD490 | 490-625 | ≥ 620 | 13 |

Size | WEIGHT | WEIGHT | QUANTITY | ||

LENGTH 6M | LENGTH 12M | LENGTH 6M | LENGTH 12M | ||

6 | 0.222 | 1.332 | 2.664 | 751 | 375 |

8 | 0.395 | 2.37 | 4.74 | 422 | 211 |

10 | 0.617 | 3.702 | 7.404 | 270 | 135 |

12 | 0.888 | 5.328 | 10.656 | 188 | 94 |

14 | 1.21 | 7.26 | 14.52 | 138 | 69 |

16 | 1.58 | 9.48 | 18.96 | 106 | 53 |

18 | 2 | 12 | 24 | 83 | 42 |

20 | 2.47 | 14.82 | 29.64 | 67 | 34 |

22 | 2.98 | 17.88 | 35.76 | 56 | 28 |

25 | 3.85 | 23.1 | 46.2 | 43 | 22 |

28 | 4.83 | 28.98 | 57.96 | 35 | 17 |

32 | 6.31 | 37.86 | 75.72 | 26 | 13 |

36 | 7.99 | 47.94 | 95.88 | 21 | 10 |

40 | 9.87 | 59.22 | 118.44 | 17 | 8 |

50 | 15.42 | 92.52 | 185.04 | 11 | 5 |

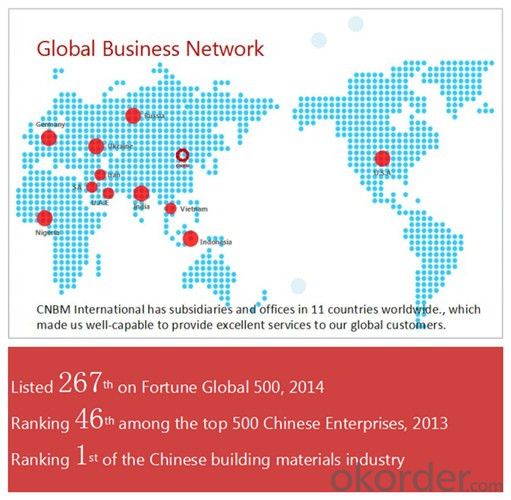

CNBM Introduction of Deformed Bars Grade JIS G3112-2004 SD345 Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Deformed Bars Grade JIS G3112-2004 SD345

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the applications of special steel in the railway industry?

- Special steel has various applications in the railway industry, primarily due to its exceptional strength, durability, and resistance to extreme conditions. It is commonly used in the manufacturing of railway tracks, ensuring their longevity and ability to withstand heavy loads and frequent train traffic. Special steel is also employed in the production of railway wheels and axles, providing enhanced wear resistance and improved performance. Additionally, it is utilized in the construction of railway bridges and tunnels, where its high tensile strength and corrosion resistance are crucial for maintaining structural integrity and safety.

- Q: What are the specific requirements for special steel used in the textile machinery industry?

- The special steel requirements for the textile machinery industry can differ based on the specific application and machinery involved. Nevertheless, there are several common requirements in this industry. Firstly, corrosion resistance is crucial as textile machinery is frequently exposed to moisture, chemicals, and other corrosive substances. Therefore, the special steel used must possess excellent corrosion resistance properties to ensure durability and longevity. Secondly, high strength is necessary since textile machinery operates under high loads and stresses. Consequently, the special steel employed must have strong characteristics to withstand these forces and prevent deformation or failure. Furthermore, wear resistance is important as textile machinery involves constant contact between different components, leading to wear and tear. Thus, the special steel utilized should exhibit good wear resistance properties to minimize friction and extend the machinery's lifespan. Additionally, heat resistance is vital as textile machinery often operates at high temperatures due to friction generated during the manufacturing process. Consequently, the special steel used should possess exceptional heat resistance to prevent deformation or loss of mechanical properties under high temperature conditions. Moreover, machinability is necessary for the special steel used in the textile machinery industry. This allows for the production of complex components with precise dimensions, ensuring smooth and efficient machinery operation. Lastly, cost-effectiveness is crucial while meeting all the aforementioned requirements. Manufacturers strive to balance performance and cost to maintain competitiveness in the market without compromising on quality. It is important to note that these requirements can vary depending on the specific application within the textile machinery industry. As a result, manufacturers and engineers must carefully evaluate their machinery's requirements and choose the appropriate special steel accordingly.

- Q: How is special steel used in the manufacturing of bearings?

- Special steel is used in the manufacturing of bearings due to its high strength, durability, and resistance to wear and corrosion. This type of steel is specifically designed to withstand the demanding conditions and loads that bearings are subjected to. It is used to create the inner and outer rings, as well as the rolling elements, of the bearing, ensuring smooth operation and increased lifespan.

- Q: Can special steel be used in the automotive racing industry?

- Yes, special steel can be used in the automotive racing industry. Special steel alloys, such as high-strength or lightweight steels, can offer enhanced performance and durability, making them suitable for various racing applications. These steels can be used in the construction of engine components, chassis, suspension systems, and other critical parts, helping to improve speed, handling, and overall performance on the racetrack.

- Q: What is the process of manufacturing special steel?

- The process of manufacturing special steel involves several steps. Firstly, raw materials such as iron ore, coal, and limestone are gathered and processed to create molten iron in a blast furnace. Next, impurities like carbon, sulfur, and phosphorus are removed through various refining techniques. Once the desired composition is achieved, the molten iron is transferred to a steelmaking furnace, where alloying elements like chromium, nickel, or manganese are added to impart specific properties. The mixture is then refined further to remove any remaining impurities and to adjust the temperature and composition. After refining, the molten steel is cast into various shapes such as blooms, billets, or slabs, depending on the desired end product. These primary forms are then subjected to hot rolling, forging, or extrusion processes to shape them into the desired final products, such as bars, plates, or wires. Finally, the manufactured steel undergoes heat treatment processes like annealing, quenching, or tempering to enhance its strength, hardness, and other mechanical properties. It is also subjected to quality control measures to ensure it meets the required specifications. Overall, the process of manufacturing special steel involves a combination of raw material preparation, refining, casting, shaping, heat treating, and quality control steps to produce steel with specific properties tailored to meet diverse industrial needs.

- Q: How does sulfur affect the machinability of special steel?

- Sulfur negatively affects the machinability of special steel by forming brittle sulfide inclusions, reducing the steel's ability to be cut, drilled, or shaped effectively.

- Q: How does special steel contribute to improved product aesthetics?

- Improved product aesthetics can be achieved through the use of special steel in various ways. Firstly, special steel can be manufactured with a higher level of precision and consistency compared to regular steel. This enables the production of products with smoother surfaces, sharper edges, and more intricate designs, resulting in a visually pleasing appearance. Furthermore, special steel can be enhanced visually through treatments or coatings. For instance, it can be polished to create a reflective surface, giving the product a luxurious and high-end look. Additionally, special steel can be coated with different colors or finishes, such as chrome or black oxide, to match specific design preferences and create a more visually striking appearance. Moreover, the superior strength and flexibility of special steel allow for unique shaping and forming possibilities. This empowers designers to create products with innovative and complex shapes, contributing to a distinct and eye-catching aesthetic. The ability to mold special steel into various forms also opens up opportunities for intricate patterns, textures, and embossed designs on the product's surface. Lastly, special steel offers excellent corrosion resistance and durability, which helps maintain the product's appearance over time. It prevents rust, staining, and other forms of deterioration that can negatively impact the visual appeal. This long-lasting aesthetic quality is particularly valuable for products exposed to harsh environments or requiring frequent handling. In conclusion, special steel significantly enhances product aesthetics through precision manufacturing, customizable surface treatments, unique shaping capabilities, and long-lasting visual appeal. These qualities allow for the creation of visually appealing products that excel in design, finish, and overall appeal.

- Q: What are the common challenges in forging special steel?

- In order to achieve desired outcomes, manufacturers and engineers must tackle several common challenges when forging special steel. One of these challenges involves maintaining precise temperature control throughout the forging process. Special steels often have specific heat treatment requirements, and any deviation from the recommended temperature range can have a negative impact on the final properties of the material. Therefore, it is crucial to achieve and sustain the appropriate temperature to ensure desired mechanical properties such as strength, hardness, and toughness. Another challenge is controlling the cooling rate during quenching. Quenching is a critical step in the heat treatment process that helps to achieve the desired hardness and strength in special steels. However, rapid cooling can lead to the formation of undesired microstructures or even cracking. Therefore, it is essential to carefully manage the cooling rate to avoid these issues and ensure optimal material properties. Additionally, shaping special steels through forging can be challenging due to their high strength and hardness. These materials are often more difficult to deform compared to regular steels, requiring higher forging pressures and specialized equipment. The resistance to deformation can result in increased wear on the forging dies, necessitating frequent maintenance and replacement. Furthermore, special steels may contain alloying elements that can affect their forgeability. Some alloying elements can promote grain growth, which can reduce the mechanical properties of the material. It is crucial to find the right balance of alloying elements and optimize the forging process parameters to achieve the desired microstructure and properties in the final product. Lastly, ensuring consistency and repeatability in the forging process can be challenging. Special steels are often produced in smaller quantities or for specific applications, making it important to maintain process control and quality assurance. Proper documentation, monitoring, and quality control measures need to be implemented to ensure that the forged special steel meets the desired specifications and performance requirements. Overall, addressing these challenges through proper process control and optimization is essential to obtain high-quality special steel products with the desired mechanical properties and performance characteristics.

- Q: How does special steel contribute to the aviation industry?

- Special steel contributes to the aviation industry by providing essential materials that are durable, lightweight, and resistant to extreme temperatures and pressure. It is used for manufacturing critical components such as engine parts, landing gear, turbine blades, and structural components, ensuring the reliability and safety of aircraft. Additionally, special steel's high strength-to-weight ratio allows for improved fuel efficiency, reducing operational costs and environmental impact.

Send your message to us

Deformed Bars Grade JIS G3112-2004 SD345

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords