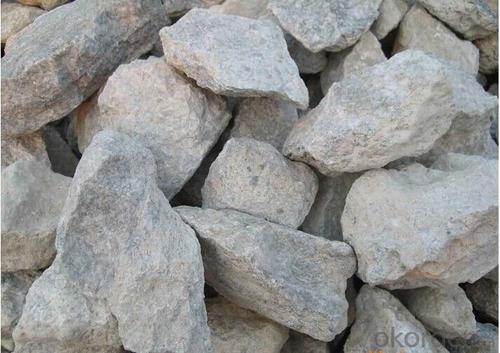

Raw Materials for Refractory:Dead Burned Magnesite Ore

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product feature:

high temperature performance and high-density, strong anti-permeability ability and easy to rapid sintering, very thin sintered layer,good thermal shock stability, strong slag-resistance, long service life and so on.

Product function:

Apply to the construction of bottom and wall of all kinds steel making electric arc furnace and ferroalloy smelting furnace for hot charging of hot metal and second hand steel

Product usage:

Mainly used in producing common magnesite brick, magnesite aluminum brick, magnesite chrome brick, gunning mix, hot patching mix for converter and EAF ect .

Product Advantage:

We can produce the products of the Dead-burned magnesite are selected natural magnesite, it is produced by mine-selecting, purifying, calcimine in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, electric furnace bottom and furnace's lining tamping.

Classifi cation | Brand | Chemical composition(%) | Size mm | Application | |||||

MgO (≥) | SiO2 (≤) | Fe2O3(≤) | CaO (≤) | Al2O3(≤) | C/S (≥) | ||||

Magnesite | M47A | 47 | 0.3 | 0.28 | - | 0.1 | 2 | 0-25; 25-350 | Fused Magnesite;Caustic Calcined Magnesite |

M47B | 47 | 0.4 | 0.30 | 0.6 | - | - | |||

M47C | 47 | 0.6 | 0.30 | 0.6 | - | - | |||

M46A | 46 | 0.8 | 0.30 | 1.2 | - | - | 0-25 | Fused Magnesite; Dead Burned Magnesite;Caustic Calcined Magnesite; | |

M46B | 46 | 1.2 | 0.4 | 0.8 | - | - | 25-350 | ||

M45 | 45 | 1.5 | - | 1.5 | - | - | 25-350 |

| |

M41 | 41 | 2.0 | - | 6.0 | - | - | 25-350 | High Calcium Synthetic Magnesite | |

Magnesite Dolomite Ore | MCa-10 | 22 | 2 | - | 10 | - | - | 25-350 | Calcium Magnesite |

MCa-6 | 22 | 2 | - | 6 | - | - | 25-350 | ||

Dolomite | MCa-28 | 20 | 1.0 | - | 28 | - | - | 25-30 | Dolomite Clinker |

MCa-26 | 20 | 1.5 | - | 26 | - | - | 25-30 | ||

- Q: What is the main constituent of refractory brick?

- The main constituent of silica?brick is monox, etc. Refractory bricks have many kinds of texture. The main constituent of high alumina brick and clay brick is aluminium oxide. The main constituent of every texture is different. The main constituent of magnesia bricks and magnesia-chrome bricks is magnesium oxide.

- Q: Are fire materials poisonous after burning?

- High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: How long is the fire resistance time of the AAAfire resistance rolling shutter door?

- How long is the fire resistance time of the AAA fire resistance rolling shutter door?

- Q: What is fireproofing material? Are fireproof materials the same thing with thermal insulation materials and refractories?

- Fireproofing material is inorganic board, while thermal insulation material belongs to organic board. Fireproof material can also preserve heat, but it is not as good as thermal insulation material in this aspect.

- Q: How to determine the fire resistance rating of the aluminium-plastic?panel?

- Fire rating of the best aluminium-plastic?panel in the current market is B1 class, and its grade classifications can refer to the national standard. I have examined factories and tested the fireproof effect of the fire-proof plate myself by burning it, and I have found that the fire-proof plate of Jinwei Aluminium-plastic?Panel in Linyi is really good in quality and fire prevention. In other words, from the single point of fire rating, the corresponding fire rating of the called fireproof aluminum (plastic) composite panel should be at least B class, and for A2 class fireproof aluminum composite panel, its core material currently doesn't include plastic element, so it's called aluminum composite panel which is of inorganic core material. If the ordinary aluminum-plastic panel is classified according to the fire-proof building material, it will belong to that of lower level. For aluminum-pastic panel used in business premises, it is required to reach the grade of flame retardant material or above this in fire prevention. It is expressly stipulated that its fire rating should be A2 class in public places.

- Q: Does anyone know fire-proof material of fireproof wooden door?

- Because the timber of fireproof wooden door has gone through fire retardant treatment, so it can prevent fire. Its principle: Fire-retardant treated timber has become flame retardant material itself and its fire endurance has increased. The commonly used method of fire retardant treatment for timber including: Spraying method, soaking method, boiling method, vacuum method, vacuum-pressure method. Spraying method and soaking method are generally used for timber surfaces which are no longer going through planing process, and thin plate fire retardant treatment, whose thickness is less than 10mm . Vacuum method and vacuum-pressure method have excellent flame retardant efficiency, but their equipment are expensive. Fireproof wooden door refers to the door whose fire endurance of door frames, skeleton of the door leaf, door panels made of timber or timber work reaches the provisions of "GB50045-95 design of tall buildings for fire protection".

- Q: Do you know where I can buy refractories?

- You can buy refractories in these places: 1. Addresses of refractory factory: No. 57, Qingshan District, Wuhan 2. Address of Qingshan refractory factory in Wuhan: Special NO.1 Xingli Road Hongshan District, Wuhan 3. Address of Xinghuo refractory factory in Hongshan district: No. 34 Qingshan District, Wuhan 4. Address of Henao refractory factory: No. 78 Jiangxia District, Wuhan

- Q: How many levels are there in the classification of PP fireproof materials?

- The level of fireproof materials: A-level: Non-combustible building materials have rare chance to burn. A1-level: Non-combustible materials, no open fire A2-level: Non-combustible materials, smoke should be tested and qualified. B1-level: Fire-retardant building materials: Fire-retardant materials are good at resisting flame. It is difficult for them to burst into fire when coming across open fire in the air or at high temperature. It will not quickly get wilder and when the fire source removes, it will be extinguished immediately. B2-level: Combustible building materials: Combustible building materials can play a certain role in preventing combustion. It will immediately burst into flames when coming across open fire or at high temperature, and will lead to fire spreading, such as wooden pillars, roof frames and beams as well as stairs. B3-level: Inflammable building materials are highly flammable with no flame retardant ability, fire risk is high.

- Q: What are fire resistant level standards of class A fire resistant door?

- Grade standards: class A fire resistant door is an important part of fire-fighting apparatus, and an important step in the social fireproof work. The quality and use of class A fire resistant door is closely related to the success or failure of the fireproof work.. There are steel and wood for class A fire resistant door materials. Only those whose fire endurance is no less than 1.5h can be called class A fire resistant door. In general, the class A fire resistant door internal material is perlite, and still some are vermiculite fireproof board, foam core board, MCcomposite materials, and other fireproofing materials. The thickness of class A fire resistant door is usually 50mm. In places where there is strict requirements for fireproof?performance, class A fire resistant door is often installed.

- Q: What are the specifications of refractory kilns ?

- Since the coefficient of thermal expansion of the basic brick is large, expansion rate is about 1-1.2% under 1000 ℃ The literature indicates that: "Under the condition that the temperature was raised to 1000 ℃ and stress in brick lining is relaxed, 300N / mm2 of compressive stress can be produced, which is equals to ten times structural strength of ordinary magnesia chrome brick, six times structural strength of magnesia chrome brick, dolomite brick and spinel brick, so any basic bricks can not afford, " the paper also pointed out that " heat expansion rate of kiln body can partially compensate for expansion rate of the inner lining of 0.2% -0.4%, which is 1/3 of thermal expansion rate of ordinary magnesia-chrome brick under 1000 ℃. However, it occurs under thermal equilibrium conditions. Thereby, the kiln should be dried slowly, allowing the temperature of the kiln body to go up slowly, thus the role of compensation can be played. " This is the key to using the basic brick. " Procedures of refractory for cement kiln "( tentative one) has clearly regulated baking and cooling of the kiln in the first section of the fifth chapters. In the heating process, in particular when the temperature is in the range of 300-1000 ℃, heating rate must be less than 60 ℃ / h. This is very clear in theory but it is difficult to implement.

Send your message to us

Raw Materials for Refractory:Dead Burned Magnesite Ore

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords