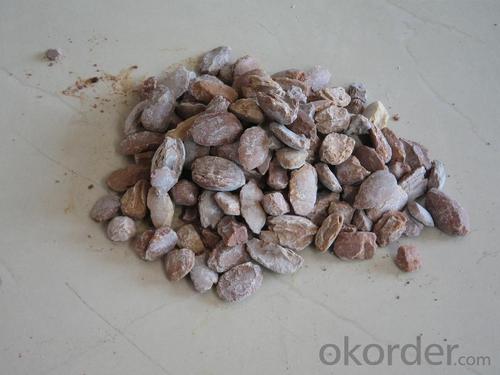

Raw Materials for Refractory:Dead Burnt Magnesite with Good Quality and Good Price (DBM)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dead Burnt Magnesite DBM

Main products level

0-1mm

1-3mm

3-5mm

0-10mm

200mesh (90% through)

325mesh

Specification

Grade | MgO (min.) | SiO2 (max.) | CaO (max.) | Fe2O3 (max.) | Al2O3 (max.) | L.O.I. (typical) |

mesh |

DBM90 | 90.00% | 1.00% | 1.50% | 0.70% | 0.10% | 1.70% |

0-400 |

DBM95 | 95.00% | 1.00% | 1.50% | 0.80% | 0.10% | 2.60% | |

DBM96 | 96.00% | 1.50% | 2.50% | 0.80% | 0.30% | 2.90% | |

DBM97 | 97.00% | 3.00% | 2.50% | 0.80% | 0.30% | 3.40% |

Usage

Mainly used in producing common magnesite brick, magnesite aluminum brick, magnesite chrome brick, gunning mix, hot patching mix for converter and EAF ect.

Features

Our factory produce the products of the Dead-burned magnesite are selected natural magnesite, it is produced by mine-selecting, purifying, calcimine in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, electric furnace bottom and furnace's lining tamping.

- Q: Who knows what is the external wall thermal insulation materials for level A fireproofing?

- In general, external wall thermal insulation materials can be divided into level A and level B by combustion grading. Level A is non-combustible material, and level B is combustible materials. A few years ago, the fire of the CCTV Building and Shenyang Hotel put the blame on the level B material. At present, the level A material is widely used, and the prices of same level A materials may be even cheaper than the level B material. Level A material is generally divided into thermal?mortar, phenolic foam board, rock wool board and foam cement board. I hope this information can be helpful to you. Hope you adopt.

- Q: What are the characteristics of the carbon composite refractories?

- The features of carbon composite refractories: 1. It is with an aggressive high thermal shock resistance 2. Good resistance to molten steel and slag

- Q: What's the material of electrical fire prevention board?

- Electrical fire prevention board uses the material of inorganic binders, which mainly includes water glass, gypsum, phosphate, and cement; refractory mineral fillers: alumina, asbestos powder, calcium carbonate, perlite, cornstarch and etc.; electrical fire prevention board is mainly aimed at fire protection and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface. Hope my answer is helpful for you.

- Q: Which one is the best refractory material?

- o make it simple, you can kindle it, and observe the burning time. If there is a professional need to be accurate, then you can send it to the professional testing company. As far as I know, the Kebiao Company over the victory bridge, Qingdao can offer professional test. I hope my answer can help you, thank you, hope to be adopted.

- Q: What 's the highest temperature can magnesium plate glass resist ?

- You just need a fire-resistance board thicker than 10 mm ,remember to add more perlite as filler during production , 12 mm plate is 80 yuan.

- Q: Development trend of refractory industry

- In recent years, great changes have taken place in the world refractory industry. On the one hand, because of the improvement of technology and equipment and refractories own industrial users of technology progress, and refractory material consumption decreased year by year; in the past 20 years, the average annual consumption per ton of steel refractories decreased about 5 kg. The forecast for the next 5 years the average annual consumption per ton of refractory materials will drop to 0.5-1.0 kg range. The trend of globalization is obvious, and the competition is so fierce that the varieties of refractory materials are diversified, and the performance and quality are obviously improved. The service consciousness and ability of the refractory enterprises are strengthened for the users. Many lack of competitiveness, no modern enterprise management awareness of SMEs have been bankrupt, mergers and acquisitions surging. The production of refractories in developed countries is much higher than the cost of developing countries at the same time, due to more stringent environmental requirements, forcing them to produce only export high value-added products or technology, and bulk products, labor-intensive production shifted to developing countries. Because of its unique advantages of raw materials and labor cost advantages, there is no doubt that China will have more opportunities

- Q: What are the best refractory materials in 2,400 Celsius degree?

- and carbon fiber or nanomaterials.

- Q: What's the fire resistance test method of doors and roller shutters?

- Fire resistance test method of doors and roller shutters: This standard specifies the fire resistance test method for roller shutter doors under standard fire conditions. The method is used to test the fire resistance of the ventilating duct when bearing the external fire (A duct) and internal fire (B duct). Fire resistance test of vertical ducts may be conducted referring to this standard. 1.Test specimen1.1 The test specimen is obtained by cutting from any part of the qualified metal tube unless otherwise relevant standard or mutual agreement specifies the cutting position of the metal tube. 1.2 Length of the specimen: L≈2.5D+50mm (D: outer diameter of the metal tube). The cut surface of the specimen must be perpendicular to the axis of the metal , and the seamed edge of the cut should be round off. Test method GB243-82 of metal tube necking 2. Test procedures 2.1 In the test, punch or press the metal tube into the tapered conical seat (see Figure) with a hammer or press machine, and make it uniformly diminished to the regulated shrinkage X which is calculated according to the following formula: Test method GB243-822 for metallic pipe necking: The inner wall of the seat cover used in the test should be polished, and has certain hardness and is coated with lubricating oil. Its conicity is 1:10, 1:5 or others in accordance with relevant standard provisions. If there is no provision, then adopt the conicity of 1:10. This standard is not suitable for: a) The pipeline whose fire resistance depends on the fire resistance of the ceiling; b) The pipeline with access door, unless otherwise the access door is included into the pipeline and tested together; c) The pipeline with two or three sides; d) Fume exhaust pipes;

- Q: Who knows what kind of fire protection material is better?

- Characteristic of polyurethane rigid foam thermal insulation decorative composite board: (1) ultra high cost performance, increased property's selling point (high cost performance) new model of thermal insulation material, excellent thermal insulation properties, elegant decorative effect, 50 years of service life, reduce maintenance costs and social waste. (2) it overcomes defects of traditional insulation technology (to solve the freezing and thawing, veneer cracking and shedding) traditional benzene board, the phenomenon of freezing and thawing that is easily appear in plastic extruded sheet, paint finish is easy to crack; its veneer facing can easily fall off; thermal insulation materials and wall are poorly adhered, easy off the whole. There is a themal bridge in dry hanging wall. (the characteristics of polyurethane composite board)

- Q: Which refractory is suitable for the tunnel kiln?

- The refractories produced by the following ten manufacturers are relatively good. They are all being the top ten brands! 1. king coconut (Chinese well-known trademarks, famous brand, the nation's largest manufacturer of wood panels, large building materials chain enterprises, Hangzhou king coconut Holding Group Co., Ltd.) 2. Fuxiang (founded in 1998, the leading professional sheet production outstanding enterprises, Fuxiang Industrial Co., Ltd.) 3. Bunny (China famous brand, China Top brand, plywood industry iconic brand, large listed companies, high-tech enterprises, Edward Bunny decoration materials Co., Ltd. 4. new Millennium boat ( Chinese well-known trademarks, famous trademarks in Zhejiang, Zhejiang famous brand, well-known trademarks in Hangzhou, Zhejiang Province key forestry enterprises, the Millennium boat Group Hangzhou Huahai Wood Industry Co., Ltd.) 5. Jin Luli (China famous brand, Chinese brand-name products, Shandong Province, to wood-based panels and steel-based enterprises, hundred private enterprises in Shandong Province, Luli Group Co., Ltd.) 6. Albert (professional fire protection board development / production and marketing of the modern manufacturer, the introduction of advanced production technology industry HPL) 7. desert oasis (China famous brand lumber, China's top ten brands plate, sheet famous Chinese brand, oasis Wood) 8. Peng Che-hung (professional fire protection board development / production and marketing of the modern manufacturer, the introduction of advanced production technology industry HPL ) 9. Worldwide (professional magnesium fire plate glass production and sales of integrated large-scale well-known enterprises, famous brands Firewood industry) 10. Mogan (national key high-tech enterprises, China's largest and most influential environment-friendly decorative materials production one of the enterprises, Zhejiang Hua Yunfeng new material Co., Ltd.)

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite with Good Quality and Good Price (DBM)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords