Marine Grade DC or CC Aluminium Sheet for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DC or CC Aluminium Sheet for Building Material

l Product Information

1) alloy number 1050 1060 1100 1200 3003.

2) temper available O H12 H14 H16 H18.

3) application: cookware utensil and basin.

4) thickness: 0.2-6.0mm.(+/-0.02mm)

5) diameter: 120-1360mm.(+/-0.5mm)

6) production treatment: cold rolled or hot rolled.

7) surface appearance: flat clean surface no whole, scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

Chemistry Composition & Mechanical Properties

l Packaging & Delivery

Packaging detail: Sea Worthy Wooden pallet

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium Products have been our featured products. We have specialized in aluminium products for about a decade and have sold our good quality aluminium products to the worldwide.

l CNBM World Wide

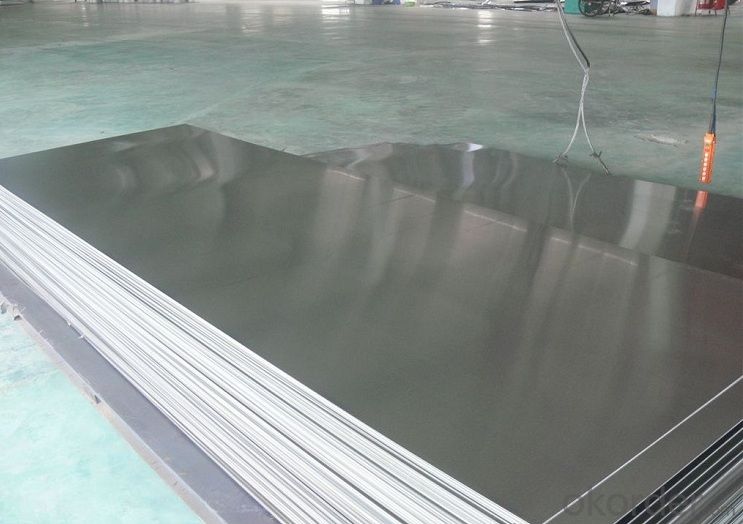

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Is it possible to use aluminum sheets in the manufacturing process of solar panels?

- <p>While aluminum sheets can be used in the construction of solar panels, they are not the primary material for making the solar cells themselves. Aluminum is typically used for the frame or backsheet to provide structural support and protection. The actual solar cells are made from materials like silicon, which is capable of converting sunlight into electricity. So, while aluminum plays a role in the assembly of solar panels, it is not used to create the photovoltaic cells that generate power.</p>

- Q: Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- The Principle behinf Microwave oven heating is that it heats up only water molecules, that is, the frequency of microwaves can only heat up water molecules ( make them oscillate and hence heat up). So if there is any trace of water or moisture on any object that you keep in the oven, it will heat up and that heat will be conducted throughout the object. Hence the foil with moisture is effectively heated whereas dry foil have no water moecule and hence will not be heated up. Hope it helps:) Can explain better if you tell me which level you are studying:)

- Q: Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Aluminum is a versatile material that can be easily shaped, cut, and formed into various designs, making it ideal for decorative applications. It can be used to create decorative panels, sculptures, signage, furniture, and many other decorative elements. Additionally, aluminum can be anodized or painted in a wide range of colors, allowing for further customization and enhancing its aesthetic appeal. Its lightweight nature and resistance to corrosion also make it a practical choice for both indoor and outdoor decorative purposes.

- Q: why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q: How thick are aluminum sheets commonly available?

- Depending on the purpose and application, aluminum sheets are typically available in different thicknesses. The most frequently found aluminum sheet thicknesses range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). Nevertheless, there are also thinner and thicker aluminum sheets obtainable, with some being as thin as 0.016 inches (0.4 mm) and others as thick as 0.25 inches (6.35 mm) or possibly more. The specific thickness needed will be contingent upon the particular project or industry application.

- Q: What are the methods to protect aluminum sheets from corrosion during their usage?

- <p>To prevent corrosion of aluminum sheets during use, several strategies can be employed. First, apply a protective coating such as paint, anodizing, or a conversion coating to create a barrier against corrosive elements. Second, ensure proper cleaning and drying to avoid the accumulation of moisture and contaminants. Third, use corrosion inhibitors in environments where aluminum is exposed to aggressive chemicals. Fourth, maintain good ventilation to reduce humidity levels. Finally, regularly inspect and maintain the aluminum sheets to address any signs of corrosion early. These measures can significantly extend the lifespan and performance of aluminum sheets.</p>

- Q: A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- determine which you do catch the Hydrogen gas in a balloon. combination Lye with water in a pitcher bottle (Coke liter bottle is huge). drop in Aluminum foil (do no longer give way) and cap off with a balloon. The balloon will fill with hydrogen. do away with the balloon, pinching the backside keeping the hydrogen; shop including Aluminum foil strips and place the balloon lower back over the precise till at last the balloon is of a sturdy length. Tie the balloon off, tape a fuse (some thing that burns slow) to the balloon, permit it bypass up interior the air. whilst the hearth its the balloon, it pops and the hydrogen + oxygen (interior the air) + spark reasons a small flash (hydrogen explosion). Do it at night for a extra advantageous view.

- Q: Can aluminum sheets be painted after installation?

- After installation, it is indeed possible to paint aluminum sheets. Aluminum, being a highly versatile and durable material, can be painted for the purpose of improving its appearance or harmonizing it with the surrounding environment. However, it is crucial to adequately prepare the surface before painting in order to ensure that the paint adheres well and lasts long. This typically involves cleaning the surface, eliminating any dirt or debris, and applying a suitable primer to enhance paint adhesion. Once the surface is prepared, various types of paint can be used on the aluminum sheet, such as acrylic, oil-based, or epoxy paint. To achieve the best results, it is advisable to seek guidance from a professional painter or carefully follow the instructions provided by the paint manufacturer.

Send your message to us

Marine Grade DC or CC Aluminium Sheet for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords