CYZ Type self priming centrifugal EX-Proof motor Oil pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

Products Introduction

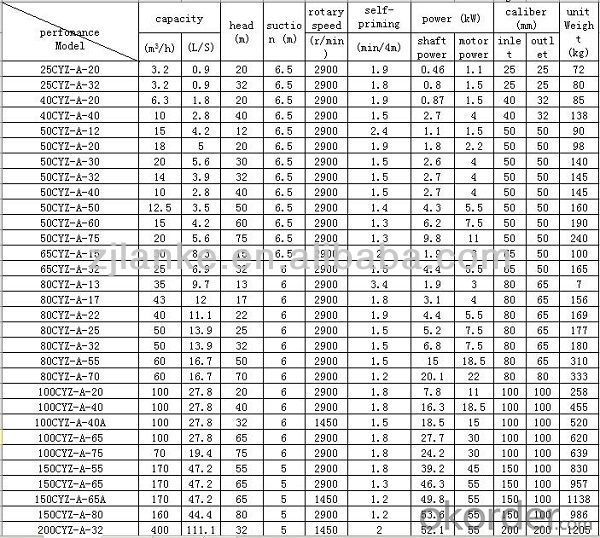

Main datas:

Capacity( flow rate) : 3.2-550 m3/h

Head : 12-80 m

Speed: 1450 / 2900 rpm

Power: 0.75 ~ 132 hp

Suction:4-5.5 m

Advantage :

1. Big pump body pass 60% of the inlet&outler solid ,

2. High suction head 4-5.5 m,have sewage

3. Used for oil and Marine, Copper impeller

4. OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

5.CE ,TUV .ISO .CO

Name: Lanco brand CYZ-A self priming Centrifugal Electric oil pump 24 volt

Summarize

CYZ-A series fuel pump is a new modified centrifugal pump which is

developed on the basis of absorbing domestic and overseas advanced technology of the same

product and combining many years design and manufacturing experience of our company.

1) Detailed instructions

Lanco brand cyz Series Siemens Electric Oil Pump

1.Flow capacity:3.2-500m3/h

2.Head: 12-80m Ciemens oil pump

3.Rotary speed: 2900rmp

4.Power: 0.75-110kw

5.Suction lift: 5-6.5m

2). Application Area

1. fuel pump is widely used totransport gasoline,kerosene,diesel oil ,oil for warehouse ,oil station ,oil tanker,dock,tank truck,airdrome ect.

2.Used in chemical industry ,pharmaceutics, brew-age,electroplate ,printing and dyeing,papermaking, electric power ,mine etc.

3. Suitable for Marine cargo pump, bilge pump, fire pump, ballast pump nd cooling water circulation machine

4. Applicable to the oil industry, oil depot, oil tank truck land .

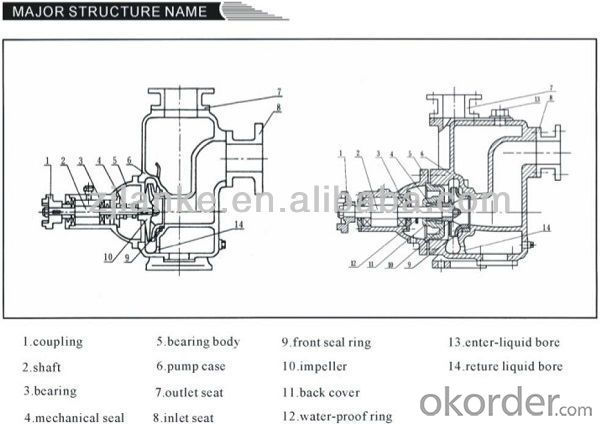

3) Oil pump characteristic 1.Simple structure,convenient operation and maintenance,stable working,hagh efficiency,

long life,good self-priming etc are its main characteristic.

2.It can also be used as pump for cleaning off cabin in tanker and water supply of ship with

high efficiency.

3.It's made up of material of high quality.Seal is hard alloy mechanical seal.So the pumps

have a long life.

4.It need not security valve in output pipeline and no bottom valve in suction valve

insuction pipeline,so it perdigests pipeline system and improves working condition.

4) Operating Condition

1.Medium temperature:-20°C~80°C,

2.Viscidity≤100centipoise

3.Particals consistency can reach 30%.

5) Mounting Configuration

| ♦ Frame Mounted |

| ♦ Base Mounted Electric Driven |

| ♦ Engine Driven SAE Mounted |

| ♦ Engine Driven Skid or Trailer Packages |

| ♦ Horizontal or Vertical V-Belt Driven |

5)Parameter

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q: How to adjust the flow of piston pump?

- Changing the size of the current in the solenoid valve can change the angle of the tilting element, and then change the stroke length of the plunger in the pump cylinder, that is to say, to change the flow of the pump. An inclined angle is called a quantitative pump, and the angle of inclination can be changed, which is called a variable pump.

- Q: Piston filling and peristaltic pump filling which precision is high?

- First of all, we should know the working principle of each, and analyze the accuracy from the principle, this problem is very important. Piston filling, such as the injection of drugs that we have been ill, the accuracy of the piston pump depends on the accuracy of the motor and the area of the unit cross section

- Q: How about the depreciation of vacuum pumps?

- (a) housing and buildings for 20 years;(two) aircraft, trains, ships, machinery, machinery and other production equipment for 10 years;

- Q: Troubleshooting of diaphragm pump

- The troubleshooting guide for diaphragm pumps, when encountered in one or more of the following situations, this information can be used as a guide to help you develop maintenance measures.As shown below, some of the abnormal operating conditions described in this guide are: A) fast circulation / low flow B) no cycle / slow cycle / irregular cycle C) leakage D) noise E) component rupture

- Q: What should I pay attention to when buying a pump?

- There are hundreds of water pump manufacturers in China, some of the family owned private enterprises are assembled in some areas, and the quality of the products is very good and bad, which makes it difficult to choose and buy. The main points are as follows:First, according to the required flow, lift, shaft power, efficiency, the necessary cavitation margin (or suction) and the use of conditions, the initial determination of the pump type, name, select the rated value and the required parameters of the same pump.

- Q: What is double hydraulic pump?

- Two hydraulic pumps installed on one shaft can be connected to increase output flow, and can also be connected to increase output pressure. See how the demand is. The system can change the mode of application at any time.

- Q: Double floor sewage pump circuit diagram of a small problem

- Question 4 when you need backup, you need to switch the SA switch, but where you want it. For example, when the 1# pump is running and does not reach the high water level, the 2# pump will not operate. If SA is placed in the left position, 21 and 22 are connected, and the KT is electrically delayed, and the KAB action causes the 2# pump to function. After the KAB operation, the KT will be disconnected, restored to the ready state, and also convenient for KT to restart the power on time, and also avoid the time relay to work on a long-term basis.

- Q: I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- HBT60.13.90S performance parametersParameter name unit HBT60.13.90SMaximum theoretical concrete conveying capacity m3/h 69/43Maximum pump outlet pressure Mpa 13/7

- Q: Harm of air pump and pump

- Centrifugal pump situationEmpty pump is divided into two kinds, if there is no liquid, then it will cause the mechanical seal of the pump to overheat, wear and even die

- Q: How many concrete pump tube diameter

- The pump is generally divided into 125 and 150 two, the inner diameter is 125mm and 150mm. And the two kinds of each have high and low pressure points. Low pressure type type 125 pump for the pipeline diameter is phi 133,

Send your message to us

CYZ Type self priming centrifugal EX-Proof motor Oil pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords