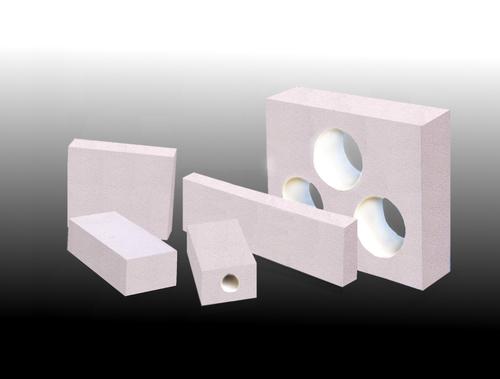

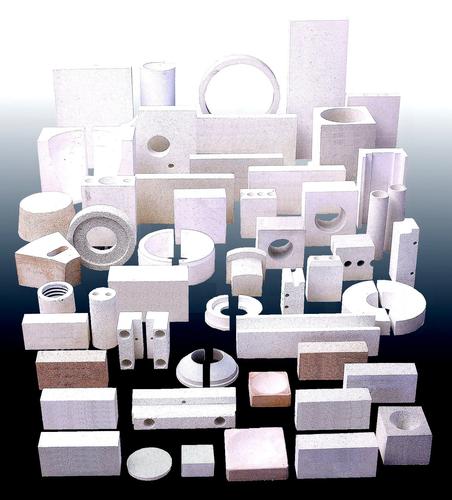

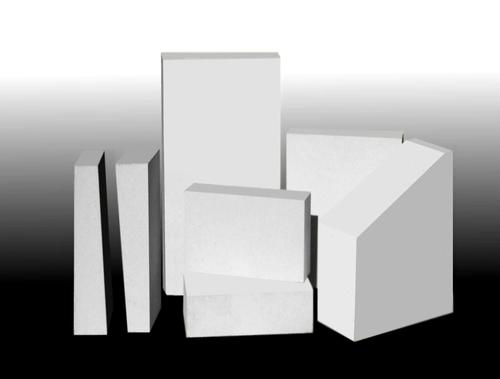

Customized Shape Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Are insulating fire bricks suitable for use in cement plants?

- Yes, insulating fire bricks are suitable for use in cement plants. Insulating fire bricks are made from lightweight refractory materials that are designed to resist high temperatures and thermal shock. These bricks have low thermal conductivity, which means they can effectively insulate against heat transfer. In cement plants, where high temperatures are generated during the production process, insulating fire bricks can be used in various applications. They can be used to line the kiln, where the raw materials are heated to extreme temperatures to produce cement clinker. The insulating properties of these bricks help to reduce heat loss and improve energy efficiency in the kiln. Additionally, insulating fire bricks can be used to line the preheater tower and other high-temperature areas in the cement plant. These bricks provide insulation and protection against the intense heat, helping to prolong the lifespan of the equipment and reduce maintenance costs. Furthermore, the lightweight nature of insulating fire bricks makes them easier to handle and install compared to traditional refractory bricks. This can save time and labor during the construction or repair of cement plant equipment. Overall, insulating fire bricks are a suitable choice for use in cement plants due to their high-temperature resistance, low thermal conductivity, and ease of installation. They can contribute to improved energy efficiency, equipment durability, and cost savings in cement plant operations.

- Q: Can insulating fire bricks be used in fertilizer plants?

- Yes, insulating fire bricks can be used in fertilizer plants. Insulating fire bricks are known for their excellent thermal insulation properties, high heat resistance, and low thermal conductivity. These properties make them suitable for various industrial applications, including fertilizer plants. In fertilizer plants, there are often processes that involve high temperatures, such as the production of ammonia or the conversion of raw materials into fertilizers. Insulating fire bricks can be used to line the walls, floors, and roofs of the furnaces, kilns, and reactors used in these processes. The thermal insulation provided by insulating fire bricks helps to minimize heat loss, increase energy efficiency, and maintain a stable temperature inside the processing units. This is crucial for controlling the chemical reactions and ensuring the optimal performance of the plant. Additionally, insulating fire bricks have a high resistance to chemical attack, which is essential in fertilizer plants where corrosive substances are often handled. They can withstand the harsh chemicals and gases present in the production environment without deteriorating or compromising their insulating capabilities. Furthermore, insulating fire bricks are lightweight, making them easier to handle and install in different areas of the plant. This can result in cost savings during construction or maintenance activities. Overall, insulating fire bricks are a suitable choice for fertilizer plants due to their thermal insulation properties, high heat resistance, chemical resistance, and lightweight nature. They can contribute to the efficient and safe operation of the plant, while also providing long-lasting performance in the demanding conditions of the fertilizer industry.

- Q: Can insulating fire bricks be used in the construction of heat storage units?

- Yes, insulating fire bricks can be used in the construction of heat storage units. Insulating fire bricks are designed to withstand high temperatures and have excellent thermal insulation properties. They are commonly used in applications where heat retention is important, such as in furnaces, kilns, and heat storage units. These bricks have low thermal conductivity, which means they can effectively retain and store heat for longer periods of time. This makes them ideal for heat storage units where the goal is to capture and store heat energy for later use. In addition, insulating fire bricks are lightweight and easy to work with, making them a practical choice for construction projects. Overall, insulating fire bricks are a suitable and reliable option for incorporating into heat storage unit construction.

- Q: Can insulating fire bricks be used in rocket stoves?

- Yes, insulating fire bricks can be used in rocket stoves. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, which makes them ideal for use in rocket stoves. They help to retain heat efficiently, ensuring better combustion and increased fuel efficiency in rocket stoves.

- Q: Do insulating fire bricks have a high insulation efficiency?

- Indeed, the insulation effectiveness of insulating fire bricks is quite high. These bricks are specifically engineered to possess exceptional thermal insulation properties. They are crafted from lightweight materials with low thermal conductivity, such as various types of refractory clay or alumina. This composition enables them to effectively minimize heat transfer via conduction, thereby making them exceedingly efficient at retaining heat within structures or appliances. Additionally, insulating fire bricks exhibit considerable porosity, which amplifies their insulation capabilities even further. The presence of numerous small air pockets within the bricks diminishes heat transfer through convection, as the air acts as an insulating barrier. This distinct structure aids in maintaining a constant and stable temperature, regardless of whether it is within a furnace, kiln, or any other high-temperature setting. Furthermore, insulating fire bricks possess remarkable resistance to thermal shock, allowing them to endure rapid temperature changes without fracturing or deteriorating. This attribute is particularly vital in applications where temperature fluctuations are commonplace, as it guarantees the longevity and effectiveness of the insulation. In summary, insulating fire bricks are renowned for their exceptional insulation efficiency. They offer superb thermal insulation, prevent heat loss, and contribute to energy conservation. Whether utilized in industrial environments or residential constructions, these bricks deliver reliable insulation performance and enhance the overall energy efficiency of the system in which they are employed.

- Q: Are insulating fire bricks resistant to moisture absorption?

- Yes, insulating fire bricks are resistant to moisture absorption. These bricks are specifically designed to have low porosity, which helps to prevent the absorption of moisture. The manufacturing process involves the use of high-quality refractory materials that are able to withstand high temperatures and resist the effects of moisture. This makes insulating fire bricks an ideal choice for applications where moisture resistance is required, such as in kilns, furnaces, and other high-temperature environments.

- Q: Can insulating fire bricks be used in the construction of coke ovens?

- The use of insulating fire bricks in the construction of coke ovens is indeed possible. These bricks are specifically designed to endure extreme temperatures and offer exceptional thermal insulation. Coke ovens, which typically operate at around 2000 degrees Fahrenheit, necessitate materials that can withstand such conditions. The low thermal conductivity of insulating fire bricks effectively hinders heat transfer between the interior and exterior of the oven. This feature helps to maintain the necessary high temperatures for coal carbonization in the coke oven, while simultaneously minimizing heat loss. Moreover, insulating fire bricks possess a lightweight composition and high strength, which makes them ideal for coke oven construction. Their lightweight nature facilitates easier installation and reduces the overall weight of the structure. Additionally, their high strength ensures that they can endure the harsh operating conditions of the coke oven without cracking or crumbling. In conclusion, insulating fire bricks are a suitable choice for constructing coke ovens due to their ability to withstand high temperatures, provide thermal insulation, and offer durability.

- Q: Can insulating fire bricks be used in contact with molten metals?

- Yes, insulating fire bricks can be used in contact with molten metals. Insulating fire bricks are designed to handle high temperatures and can withstand the heat generated by molten metals. They have excellent insulation properties and can effectively protect against heat transfer, making them suitable for various applications involving molten metals.

- Q: Can insulating fire bricks be used as a structural component in a building?

- Using insulating fire bricks as a structural component in a building is not recommended. These bricks are primarily designed to provide thermal insulation and are not meant to bear significant structural loads. Their low density and strength make them unsuitable for structural purposes, unlike traditional bricks or concrete blocks commonly used. Insulating fire bricks are better suited for applications that require thermal insulation, such as lining furnaces, kilns, or chimneys. When constructing structural components in buildings, it is crucial to use materials that have been specifically designed and tested to meet the necessary load-bearing capacities and safety standards.

- Q: Do insulating fire bricks have any insulating properties when wet?

- Insulating fire bricks do have some insulating properties when wet, but their effectiveness is significantly reduced compared to when they are dry. When wet, the water fills the pores in the bricks, which increases their conductivity and reduces their ability to trap heat or cold. This means that the insulating properties of the bricks will be compromised to some extent when they are wet. Therefore, it is advisable to ensure that insulating fire bricks are kept dry in order to maintain their optimal insulating capabilities.

Send your message to us

Customized Shape Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords