Customized Color Coated Aluminum Coil - Aluminum Profile 6060 6061 6063 6082 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Profile 6060 6061 6063 6082 Grade Aluminium ProfileDescription:

Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

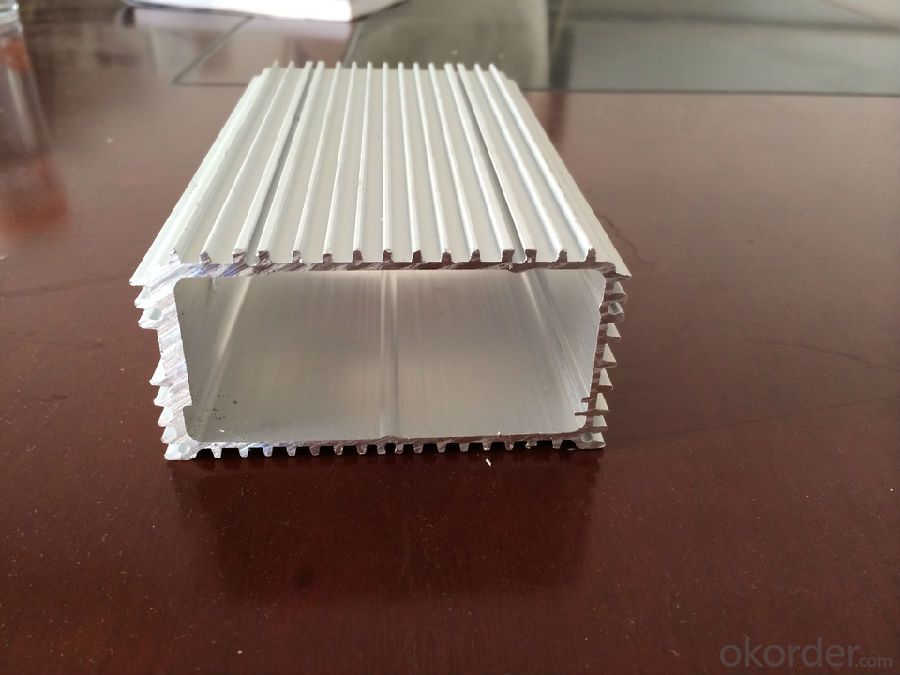

3.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Images:

4.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: What are the properties of aluminum coils?

- Aluminum coils are highly sought after in various industries due to their numerous key properties. Firstly, they possess a high strength-to-weight ratio, which means they are both lightweight and durable. This makes them ideal for industries like aerospace, where reducing weight is crucial. Furthermore, aluminum coils exhibit exceptional corrosion resistance. The formation of a thin oxide layer on the metal surface prevents further oxidation, making them suitable for outdoor and marine environments. This corrosion resistance also extends their lifespan, reducing maintenance costs. Another important property of aluminum coils is their high thermal conductivity. This allows for efficient heat transfer, making them well-suited for applications in the HVAC industry. Additionally, they have excellent electrical conductivity, making them favorable for use in electrical and electronic components. Aluminum coils are also highly malleable and ductile, allowing for easy shaping and forming. This versatility makes them popular in manufacturing processes, such as the production of automobile parts, cans, and packaging materials. Lastly, aluminum coils are known for their recyclability. They can be easily melted down and reused without compromising their quality, making them an environmentally friendly choice. This aligns with the increasing focus on sustainability and reducing the environmental impact of industries. In conclusion, aluminum coils possess valuable properties such as high strength-to-weight ratio, corrosion resistance, thermal and electrical conductivity, malleability, and recyclability. These properties make them valuable in numerous applications across various industries.

- Q: What are some normal everyday products made from aluminum that I can use to recycle?

- cool drink cans.

- Q: Who knows Xingtai aluminum shutter door how much is one square meter?

- Two floor is right, you have to use a thick price on the high. A good job, 2012 way, is dead, and get a color to cope with it, ha ha.

- Q: What is the maximum temperature aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand is influenced by several factors, which include the particular alloy of aluminum and the intended application of the coils. In general, aluminum has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). Nevertheless, when it comes to aluminum coils employed in diverse industries like HVAC systems and electrical appliances, they are typically engineered to function within a temperature range of -30 to 150 degrees Celsius (-22 to 302 degrees Fahrenheit). These temperature boundaries guarantee that the aluminum coils maintain their structural integrity and avoid any notable degradation or harm. To ascertain the maximum temperature tolerance of the specific aluminum coils in question, it is crucial to refer to the manufacturer's specifications or guidelines.

- Q: How do aluminum coils contribute to the energy efficiency of products?

- Aluminum coils play a crucial role in enhancing the energy efficiency of various products. Firstly, aluminum is known for its excellent thermal conductivity, which allows for efficient heat transfer. This characteristic enables aluminum coils to quickly and effectively transfer heat between different components within a product, such as in air conditioning systems or refrigerators. By efficiently dissipating heat, aluminum coils help these products operate more efficiently, reducing energy consumption and ultimately saving costs for consumers. Additionally, aluminum is a lightweight material, which makes it easier to incorporate into various products without adding unnecessary weight. This is particularly beneficial for industries such as automotive and aerospace, where reducing weight is essential for improving fuel efficiency. By using aluminum coils in these applications, manufacturers can achieve lighter and more energy-efficient vehicles or aircraft, resulting in reduced fuel consumption and emissions. Furthermore, aluminum coils offer excellent corrosion resistance. This is especially advantageous in products exposed to moisture or harsh environments, as it prevents rust and degradation over time. By maintaining the performance and integrity of the coils, the overall energy efficiency of the product is preserved, ensuring that it operates optimally for an extended period. In conclusion, aluminum coils contribute significantly to the energy efficiency of products through their thermal conductivity, lightweight properties, and corrosion resistance. By effectively transferring heat, reducing weight, and preventing degradation, these coils help products operate more efficiently, resulting in lower energy consumption, cost savings, and reduced environmental impact.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is a commonly used material for electrical conductors due to its excellent electrical conductivity and relatively low cost compared to copper. It is especially used in power transmission and distribution cables where long-distance transmission is required. Aluminum coils are often used in overhead power lines and underground cables. However, it is important to note that aluminum has a lower tensile strength than copper, so the cables need to be properly designed and manufactured to ensure adequate mechanical strength. Additionally, aluminum conductors require larger cross-sectional areas compared to copper to achieve the same electrical performance, which can result in slightly larger cable sizes.

- Q: We have all heard the Us saying aluminum and their euro counterparts saying aluminium. I assumed this was just a small difference in culture or location. But, while reading my chemistry book (Chemistry the Central Science 12th) i came across a section saying: Cations formed from nonmetal atoms have names that end in -ium: NH4+ ammonIUM ion, H3O+ hydronIUM ion. So, i have came up with a hypothesis, could it be possible that when the periodic table was coming together, the aluminium was changed to aluminum to allow the rules to work? Thus making aluminum the correct spelling? Give me your thoughts.

- www.okorder ... aluminum (n.) 1812, coined by English chemist Sir Humphry Davy (1778-1829), from alumina, name given 18c. to aluminum oxide, from Latin alumen alum (see alum). Davy originally called it alumium (1808), then amended this to aluminum, which remains the U.S. word, but British editors in 1812 further amended it to aluminium, the modern preferred British form, to better harmonize with other metallic element names (sodium, potassium, etc.).

- Q: Can aluminum coils be coated with protective films?

- Yes, aluminum coils can be coated with protective films. These films provide a layer of protection against scratches, corrosion, and other damage, helping to prolong the lifespan and enhance the appearance of the aluminum coils.

- Q: How are aluminum coils used in the electrical industry?

- Aluminum coils are widely used in the electrical industry for various applications such as transformers, motors, generators, and electrical transmission systems. These coils are used to create electromagnetic fields, which are essential for the functioning of these electrical devices. Additionally, aluminum coils are preferred due to their lightweight, high thermal conductivity, and cost-effectiveness compared to other materials.

Send your message to us

Customized Color Coated Aluminum Coil - Aluminum Profile 6060 6061 6063 6082 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords