High Strength Insulating Corundum Mullite Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

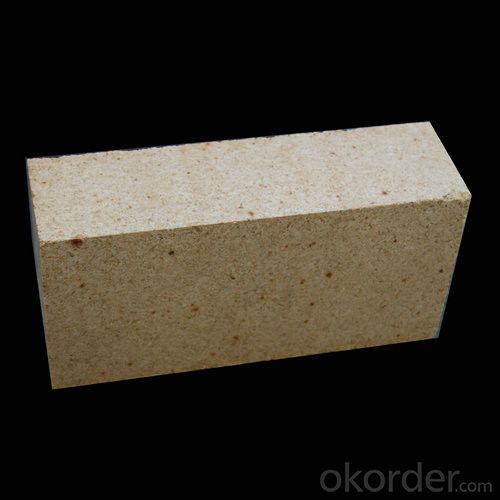

General Information of Corundum Bricks

CMAX corundum bricks use compact electro-smelted corundum and alumina powder as main raw materials, shaped under high pressure after machine-blending and fired at high temperature.

Image of Corundum Bricks

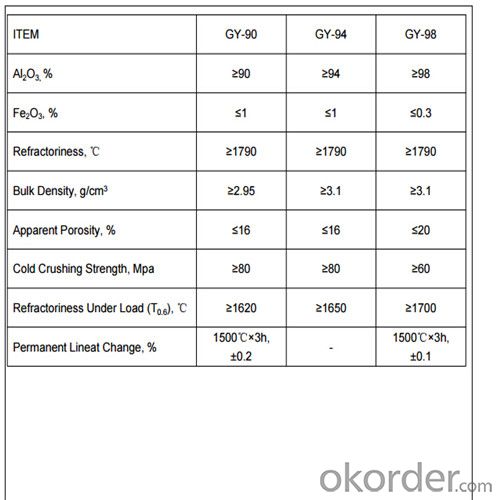

Technical Data of Corundum Bricks

Feature of Corundum Bricks

Low porosity

High compressive strength

Good chemical stability

Application of Corundum Bricks

Linings of high-temp industrial kilns and furnaces

Why Choose Us

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- The compact microstructure of AZS33# zirconia corundum brick makes the bricks resistant to glass liquid corrosion, and it is difficult to produce stone or other defects in the glass kiln. It is the most widely used product in the glass furnace. It is mainly applied to the upper structure of the melting pool, the wall brick of the working pool and the paving brick, the material way, etc..

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The refractory bricks, which are suitable for blast furnace conditions, are vitrified by high temperature sintering. They are like a huge cup, so they are called ceramic cups. The name was taken by the French, and the technology was handed down from france!

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: Expansion ratio of lightweight corundum refractory bricks

- Light corundum refractory brick, because of its production methods and the introduction of different additives, there are certain differences in the content of Al2O3, just burn add general light corundum refractory brick and foam and gasification method cannot be made, the content of Al2O3 is generally not more than 99%, with alumina hollow ball manufacturing transfer are corundum brick with high content of Al2O3.

- Q: What refractory materials are used in industrial furnaces?

- The working conditions of industrial furnaces should first be investigated thoroughly, and the primary and non essential factors affecting the construction of furnace materials shall be analyzed. Focus on thinking, the temperature change condition, temperature bump slag properties, furnace atmosphere, heat insulation, impact wear and other special requirements, to ensure the quality of the life and product.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: What is the hardness of corundum refractory bricks?

- Al2O3 containing more than 90% greater than the refractory brick called corundum refractory brick, also known as pure alumina refractory products. Corundum has a high hardness (9 Mohs hardness) and a high melting point. These are closely related to the firmness of the Al - 0 bond in the structure. Therefore, a-Al2O3 is the main phase of making high temperature refractory bricks and high temperature electrical insulating materials.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Cast brick and clay brick masonry contact, eutectic phenomenon will occur at 1300 degrees Celsius, the selection of refractory materials, should avoid eutectic phenomenon serious two kinds of refractory materials such as brick masonry contact, in the following cast brick, the most vulnerable to erosion fused zirconium corundum brick.

Send your message to us

High Strength Insulating Corundum Mullite Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords