Corundum Mullite High Temperature Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

In order to catch the rapid increasing demand of grinding media and provide full series to customers,we have developed grinding media with 92% AI2O3,75% AI2O3 AND 65% AI2O3.The technical data of each series is listed as following table.

With overwhelming merits in higher density,more regular shape,easily classifying and assorting,superior grinding efficiencies and competitive price prior to natural cobble stones and conventional grinding media,our Alumina Grinding Media are excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

Specifications

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. Low heat capacity

4. Low content of impurities

5. High insulation

6. Excellent thermal shock resistance

7. Low density

Features

1.High density

2.Strong corrosion resistance

3.Good slag resistance

4.Low permannent liner change on reheating

Application

Corundum brick primarily used for the key parts of the industrial furnace of steel,metallurgica,electronics,petrochemical,chemical fertilizers,non-ferrous metals,refractorty material etc high temperature industrial kiln furnace,such as glass furnace,cement kiln, heaters molten steel ladle,metallurgical furnaces for nonferrous metals and furnaces for chemical engineering industries.

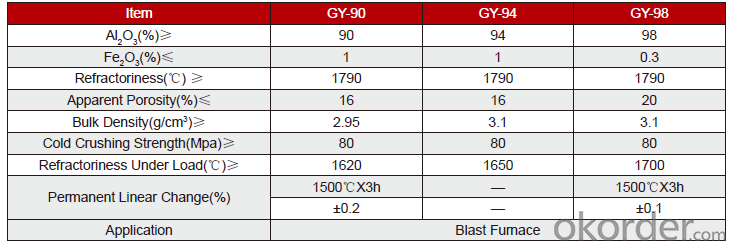

Physical properties and chemical composition

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- In addition to AZS33# and AZS same co crystallization in vitro, 36#AZS due to the increase of chain like zirconia brick more crystals, while the glass phase content is low, so 36# AZS corrosion resistance has been further enhanced, so is suitable for the rapid flow of molten glass or high temperature region.AZS36 s is an excellent product in the AZS series. It has high resistance to glass liquid erosion and low pollution. It is usually used in the key parts of the glass furnace, such as the pool wall near the hot spot.

- Q: How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- In fact, a kind of ceramic cup of blast furnace refractories, application in blast furnace bottom and hearth contact steel lining using a layer of non carbon refractory materials, such as Theron with corundum brick, corundum mullite and synthetic mullite bricks etc..

- Q: What's the jade stove for?

- Corundum furnace for corundum smelting furnace, usually electric arc furnace for smelting dense corundum, corundum, white corundum, zirconia corundum, magnesia, magnesium aluminum spinel and fused refractory materials, professional design, Xi'an Xinda furnace engineering limited liability company manufacturing corundum furnace.

- Q: Which is good, glazed brick and whole cast glazed brick?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- The fused zirconia corundum brick is made up of 30% ~ 41% zirconia two in the alumina burden. The main mineral compositions are corundum, zircon and glass phase. The main varieties are fused (or cast) zirconium corundum brick (also known as AZS casting brick) and sintered zirconia corundum brick. Generally speaking, zircon corundum brick means sintered zirconia corundum brick. It is made from alpha -Al2O3, partially stabilized zirconia and zircon corundum clinker, which is prepared by proportioning and molding at 1700~1750 DEG C and then sintered at two. The sintered zirconium corundum brick has a strong resistance to molten glass, and its thermal shock resistance is stronger than that of fused zirconia corundum brick. It is mainly used as lining of glass furnace and induction furnace, as well as steel rolling furnace, slide rail, etc..

- Q: What are the refractory materials?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick by using chromium oxide as the main component of the corrosion resistance of steel slag is good, but the poor heat shock resistance, high load low deformation temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, heat vibration performance, high strength, corrosion resistance to acid and salt, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

Send your message to us

Corundum Mullite High Temperature Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords