Factory of Corundum Mullite BricksRefractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Factory of Corundum Mullite Bricks\Refractory Bricks

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Mullite |

| SiO2 Content (%): | 0 | Al2O3 Content (%): | ≥90 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | follow as customer's requirement | Brand Name: | |

| Refractoriness(°C): | ≥1750 | Bulk density(g/cm3): | ≥3.0 | Apparent porosity(%): | ≤18 |

| Cold crushing strength(Mpa): | ≥100 | Refractoriness under load(0.2MPa)(°C): | ≥1700 |

Packaging & Delivery

| Packaging Details: | on wooden pullet covering by PE membrane or by customer's requirment |

| Delivery Detail: | within 30days after deposit |

Product Description

Fireclay Brick/Clay Brick/Refractory Brick/Fire Brick

Features:

1. Low thermal conductivity.

2. High strength and resistance to corrosion.

3. Low heat capacity.

4. Low shrinkage after heavy firing.

5. High insulation.

6. High refractoriness.

7. Low density.

8. Good thermal shock resistance under high temperature.

9. Thermal insulation energy-saving effect is good.

Application:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Physial properties and chemiacal composition

| Item | High Quality and High Purity Corundum Brick | Sinter Corundum Brick | Mullite-Corundum Brick |

| Al2O3(%) ≥ | 99 | 90 | 80 |

| SiO2(%) ≤ | 0.8 | 8 | 18 |

| Fe2O3(%) ≤ | 0.2 | 0.2 | 0.3 |

| Bulk Density(g/cm3) ≥ | 3.2 | 3 | 2.8 |

Apparent Porosity(%) ≤ | 19 | 18 | 18 |

| Cold Crushing Strength(Mpa) ≥ | 100 | 100 | 100 |

| Refractoriness Under Load(0.2Mpa,0.6%)( ℃ ) ≥ | 1700 | 1700 | 1700 |

| Application | Primarily used for the key parts of the industrial furnace of steel,electronics,petrochemical,fertilizers,non-ferrous merals,refractory material,etc | ||

1.Strong professional:

Our compay has many year producing experiece in refractory product.Our manager supervise on a various refractory's production materials,process control,quality supervision and package delivery,and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system certification.And the annual supply of shaped and unshaped refractory product is 3000-5000tons per month.

3.Annual exports:

Now we have gained a global sales network reaching Russia,Mongolia,South Korea,Vietnam,Pakistan,Bulgaria,Finland,Greece,Spain,Congo,Angola,South Africa,and Maldives,Jordan,United Kingdon,United States and so on.

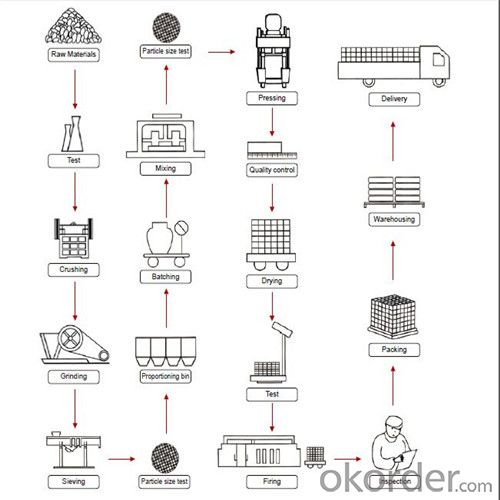

4.Production equipment:

Production and testing equipments are new,complete and automated or semi-automated.Such modern facilities and equipment have proviede the fine technical guarantee for the production and testing.

5.Testing equipment:

Our company's testing equipmets as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

6.Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Warmly welcome friends and customers all over the world to pay a visit to factory!Hopefully both of us can establish a long-term cooperation!

FAQ

3.Common question:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What is the whole process of doing business with us?

A:1.First,please provide details of the products you need we quote for you.

2.If price is acceptable,we provide Proforma Invoice.If need the sample to do a test,we will send a sample to PI to you for doing the payment.

3.If client approve sample and require for sample production for order,we will provide Proforma Invoice for client.and we will arrange to produce at once when we get 30% deposit.

4.We will send photos of all goods,packing,details after goods are finished.After be confirmed by clients,Pls transfer the balance 7.% for the order.We will arrange shipment and send all orginal docs to you.

Q4: What advantages we have?

A: 1.Rich experience:We have more than 10 years experience in this industry.That means,we can preview the problems for the orders and products. Therefore,it will make sure to reduce the risk of bad situation to happen.

2.Best technique:We have a strong technique team so that can explain the usage process and settle technique problem for production.If you need,we can visit your company to offer the technique support for your produce line.

3.Offer all line service:For the new manufacture,we can offer professional guidance and offer complete set material to you for your products which you need to make.

4.Point to point service:There is one sale who will serve you from inquiry to products shipped out.During the process,you just need to discuss with her for all problems and the way saves much time.

5.Free design:for the mold,If you are not ready for the designs,the professional designers will be able to help you with it freely, you just offer size is ok.

6.Strict QC:For each order,strict inspection will be carried out by the QC department before shipping. The bad quality will be avoid within door.

7.Shipping:We have shipping department and forwarder,so we can promise faster delivery and make the goods well protected.

Thanks for your coming in,if there is any question,I will be glad to help you.

Welcome to enquire!

We will offer you the best price with high quality!

- Q: How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: Which is good, glazed brick and whole cast glazed brick?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q: What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: Ask for help about the phase of refractory material

- Secondary crystalline phase. The second phase and second phase or second phase, and the main crystal phase and is in high temperature liquid phase coexistence in refractory material, the number and influence on high temperature properties of materials is the main crystal phase is small second phases. As to the main crystalline phase of periclase magnesia chrome brick, magnesia brick, magnesia brick and magnesia calcium brick respectively containing Cr spinel, spinel, forsterite and calcium silicate two are secondary phase. There are structure of refractory refractory material in the crystal phase, especially the direct combination of high melting point and so on, the resistance to high temperature also tend to benefit. Compared with the ordinary brick, the second phase of the refractory products, make the products refractoriness under load are improved. Many according to mineral composition of refractory material named, such as mullite corundum brick, corundum mullite brick, is its main crystal phase and the second phase composite named. The former is mainly crystal phase, the latter is sub crystalline phase.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What can zirconium sponge do for those industries?

- Zirconium metal, also known as sponge zirconium, silver gray metal, the appearance of steel, shiny; melting point 1852 points, sub points, boiling point 4377 density 6.49. Zirconium is easy to absorb hydrogen, nitrogen and oxygen; zirconium has a strong affinity for oxygen; at 1000 DEG C oxygen dissolved in zirconium can make its volume increase significantly. Zirconium is relatively stable in the air; powder zirconium is easy to burn; fine zirconium wires can be ignited by matches; at high temperatures they can be combined directly with dissolved oxygen, nitrogen and hydrogen.

Send your message to us

Factory of Corundum Mullite BricksRefractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords