Corundum Mullite Refractory Bricks for High Hot Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

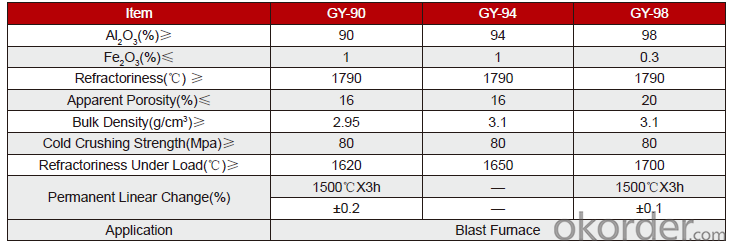

In order to catch the rapid increasing demand of grinding media and provide full series to customers,we have developed grinding media with 92% AI2O3,75% AI2O3 AND 65% AI2O3.The technical data of each series is listed as following table.

With overwhelming merits in higher density,more regular shape,easily classifying and assorting,superior grinding efficiencies and competitive price prior to natural cobble stones and conventional grinding media,our Alumina Grinding Media are excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

Specifications

1.Excellent corrosion resistance

2.The alumina content is over 96%

3.Used in glass furnace

Features

1.High density

2.Strong corrosion resistance

3.Good slag resistance

4.Low permannent liner change on reheating

Application

High purity corundum brick is usually used in petrochemical industry. In addition, it is also adopted as high temperature interlayer between AZS ans basic bricks in order to avoid the reaction of interface at high temperature.

Physical properties and chemical composition

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- AZS33 is the casting of AZS series of the largest, most widely used in tea, to prevent the pollution of liquid glass is excellent. Widely used in the glass furnace pool wall, pool bottom, the upper structure and feeding routes and other parts.

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- Plus all the cables fifty thousand. Steel 10000 yuan. Corundum bricks; insulating bricks; clay bricks, these three require more than ten thousand. The electrode is about one hundred thousand. It's just an investment in an electric furnace. Together with the rear section processing and raw materials need hundreds of thousands of.

- Q: Which is good, glazed brick and whole cast glazed brick?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Two aluminum liquid hydrogen phosphate using spray paint, cement, refractory castable and binder for foundry industry, mainly used in refractory industry corundum, chromium corundum nozzle coal water slurry gasifier with chromium aluminum zirconium corundum brick production.

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum refractory material of glass fiber kiln quantity is little, generally used in the kiln feed arch furnace flue, where large amount of places are currently using dense zirconium Zr, dense chromium

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: Ask for help about the phase of refractory material

- Binding phase. The binding phase is the phase outside the main crystal phase or the main crystal phase and the sub crystalline phase. The binding phase can be made up of either a fine crystal or a glass phase or a composite of the two. Such as the combination of magnesia brick, magnesia chrome brick, magnesia brick and other basic refractories in phase is composed of crystal matrix; silica brick, clay brick is made of glass phase in the form. When the matrix is formed at high temperature, the liquid phase is low, and the viscosity of the liquid phase is low and the quantity is large, the production and properties of refractory products are essentially controlled by the substrate.

- Q: What are the refractory materials?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

Send your message to us

Corundum Mullite Refractory Bricks for High Hot Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords