Corundum Mullite Bricks with Excellent Thermal Properties

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is Corundum Brick?

l Corundum Bricks are high alumina refractory bricks are made for extreme demands. The alumina content in Corundum Bricks can be traced to the use of synthetic corundum of high purity, such as white fused alumina or tabular alumina. Additional ingredients are special refractory clays, reactive alumina and very pure modifications of silica.

l Corundum Bricks are fired at high temperatures to form a matrix with mullite, mullite-corundum or corundum that has excellent volume stability.

l The service temperature for Corundum Bricks goes up to 1800°C.

Image of Corundum Brick

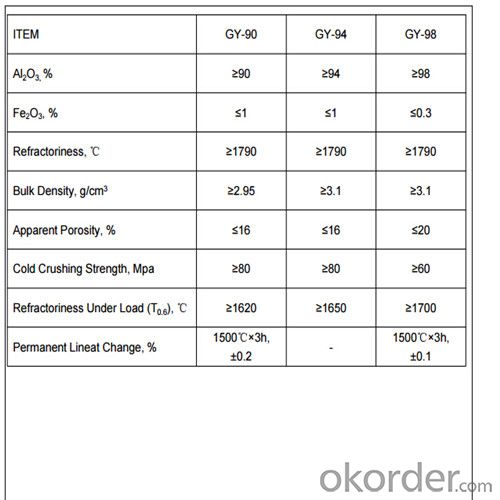

Technical Data of Corundum Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: Application of electric high temperature regulating valve?

- Now, the definition of refractories has not only depended on the degree of refractoriness is more than 1580 degrees celsius. At present, refractory materials refer to inorganic non-metallic materials used in metallurgy, petrochemical, cement, ceramics and other production equipment lining.

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What is the main component of corundum?

- The name of corundum originates from India and is the name of mineralogy. There are three main variants of corundum Al2O3, which are alpha -Al2O3, beta -Al2O3 and gamma -Al2O3 respectively. Corundum is second only to diamond.

- Q: Wave tile and throwing glaze, tile which good?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q: Expansion ratio of lightweight corundum refractory bricks

- Light corundum refractory brick, because of its production methods and the introduction of different additives, there are certain differences in the content of Al2O3, just burn add general light corundum refractory brick and foam and gasification method cannot be made, the content of Al2O3 is generally not more than 99%, with alumina hollow ball manufacturing transfer are corundum brick with high content of Al2O3.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum brick has a strong resistance to glass liquid corrosion!It is better to fuse the furnace with fused zirconia corundum bricks.Fused zirconia corundum brick, regardless of the size of the furnace, the use of small hundreds of kilograms can be used, depending on the design of the kiln!

- Q: What are the refractory materials?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: What kind of rock is corundum produced?

- If Ti4+ and Fe2+ containing a small amount of blue, a sapphire; containing six symmetrically distributed acicular rutile or other inclusions in some crystals, can produce six star awn, known as star ruby or sapphire stars, are precious stones. Corundum is vitreous luster with no cleavage, but cracks occur because of the presence of poly twin crystals that are often formed by the base or face of a face. Specific gravity 3.98. Of relatively low silicate igneous and metamorphic rocks and common in alluvial deposits. The U.S. state of North Carolina and Georgia, Russia's Ural mountains, South Africa as the main origin of the transvaal.

Send your message to us

Corundum Mullite Bricks with Excellent Thermal Properties

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords