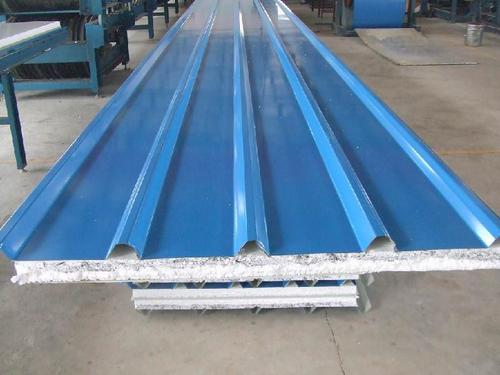

Corrugated steel sheets for roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/9/1000/1200/1219/1220/1250mm |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technical data :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

|

|

|

|

|

| |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: Do the steel sheets have any specific fire ratings?

- Yes, steel sheets often have specific fire ratings due to their inherent fire-resistant properties. These ratings indicate the duration of time the steel sheet can withstand exposure to fire before it loses its structural integrity. The fire ratings are determined through rigorous testing and certification processes.

- Q: What is the process of galvalume coating on steel sheets?

- The process of galvalume coating on steel sheets involves the application of a zinc-aluminum alloy coating to protect the steel from corrosion. This is typically done through a continuous hot-dip process where the steel sheet is passed through a bath of molten zinc-aluminum alloy. The sheet is then cooled and solidified, resulting in a durable and corrosion-resistant coating on the surface.

- Q: What is the typical fatigue strength of a steel sheet?

- The typical fatigue strength of a steel sheet depends on various factors such as the steel grade, thickness, surface condition, and the specific loading conditions. It is usually determined through fatigue tests conducted under controlled laboratory conditions. Therefore, it is difficult to provide a specific value without considering these variables.

- Q: What are the different sheet metal bending techniques for steel sheets?

- There are several sheet metal bending techniques commonly used for steel sheets. These techniques allow for the manipulation and shaping of steel sheets to achieve desired forms and angles. Some of the most common techniques include: 1. V-bending: This technique involves using a V-shaped punch and die set to create a sharp bend in the steel sheet. The material is placed between the punch and die, and force is applied to form the desired angle. V-bending is a versatile technique that can create various angles and shapes. 2. Air bending: In this technique, a punch is used to press the steel sheet into a V-shaped die, but without completely contacting the material. The bending is achieved by controlling the depth of penetration of the punch into the material. Air bending allows for greater flexibility in terms of angle adjustments and requires less force than other techniques. 3. Edge bending: As the name suggests, this technique involves bending the edge of the steel sheet. It is commonly used to create flanges or edges with specific angles. Edge bending is achieved by clamping the sheet between a punch and a die, and applying force to bend the material along the edge. 4. Bottom bending: This technique is used to create larger bends in steel sheets. It involves clamping the sheet between a punch and a V-shaped die, and then applying force to bend the material around the die. Bottom bending is suitable for creating U-shaped parts or boxes. 5. Roll bending: Also known as cylindrical bending, this technique is used to create cylindrical or curved shapes in steel sheets. The sheet is passed through a set of rolls, which gradually bend the material into the desired shape. Roll bending is commonly used in the production of pipes, tubes, and cylinders. 6. Coining: Coining is a precision bending technique that creates crisp, sharp bends. It involves pressing the steel sheet between a punch and a die, with the die featuring a sharp edge. The material is subjected to high pressure, resulting in a precise and defined bend. These are just a few of the many sheet metal bending techniques available for steel sheets. Each technique has its advantages and applications, and the choice of technique depends on factors such as the desired angle, the thickness of the sheet, and the complexity of the shape being formed.

- Q: Can steel sheets be used in the construction of bridges?

- Yes, steel sheets can be used in the construction of bridges. Steel sheets are commonly used as structural components for various types of bridges due to their high strength, durability, and resistance to corrosion. They provide excellent load-bearing capacity and can be easily fabricated and assembled, making them a popular choice in modern bridge construction.

- Q: Can steel sheets be used for interior wall cladding?

- Yes, steel sheets can be used for interior wall cladding. They can provide a modern and industrial aesthetic, are durable, and can be easily cleaned. However, it is important to consider proper insulation and fireproofing measures when using steel sheets for interior applications.

- Q: Can steel sheets be rolled into cylinders or tubes?

- Yes, steel sheets can be rolled into cylinders or tubes through a process called roll forming.

- Q: What are the benefits of using pre-painted steel sheets?

- There are several benefits to using pre-painted steel sheets in various applications. Firstly, pre-painted steel sheets offer enhanced durability and longevity compared to other materials. The paint coating on these sheets provides a protective barrier against corrosion, rust, and weathering, ensuring that the steel remains in excellent condition for an extended period of time. This makes pre-painted steel sheets ideal for outdoor use, where they are continuously exposed to harsh environmental conditions. Secondly, pre-painted steel sheets offer a wide range of color options and finishes, allowing for greater design flexibility. Whether it's for architectural purposes, interior decoration, or industrial applications, the availability of different colors and finishes enables the creation of aesthetically pleasing and visually appealing structures or products. Additionally, pre-painted steel sheets are easy to maintain and clean. The paint coating makes them resistant to stains, dirt, and grime, making them easier to keep clean and requiring less maintenance over time. This makes them an attractive choice for applications where cleanliness and hygiene are essential, such as in the food and beverage industry or healthcare facilities. Furthermore, pre-painted steel sheets are highly versatile and can be used in a wide range of industries and applications. From roofing and cladding to automotive parts, appliances, and furniture, pre-painted steel sheets provide a reliable and cost-effective solution for various purposes. They can be easily fabricated, cut, and formed into desired shapes and sizes, making them suitable for diverse manufacturing processes. Lastly, pre-painted steel sheets are environmentally friendly. The paint coatings used on these sheets are typically formulated to be low in volatile organic compounds (VOCs), reducing their impact on air quality and human health. Additionally, the durability and longevity of pre-painted steel sheets contribute to a longer lifespan, reducing the need for frequent replacements and minimizing waste. In conclusion, the benefits of using pre-painted steel sheets include enhanced durability, a wide range of design options, easy maintenance, versatility, and environmental friendliness. These advantages make pre-painted steel sheets a preferred choice for many industries and applications.

- Q: Can steel sheets be used in the construction industry?

- Yes, steel sheets can be commonly used in the construction industry. Steel sheets are highly versatile and have a wide range of applications in construction. They are used for various purposes, including roofing, wall cladding, flooring, and structural components such as beams, columns, and trusses. Steel sheets are preferred due to their high strength-to-weight ratio, durability, and resistance to corrosion. They can withstand heavy loads and provide stability and structural integrity to buildings. Additionally, steel sheets can be easily fabricated, allowing for customization and efficient construction processes. Overall, steel sheets are a popular choice in the construction industry due to their numerous advantages and suitability for various construction applications.

- Q: Are steel sheets suitable for playground equipment?

- Yes, steel sheets are suitable for playground equipment. Steel is a durable and strong material that can withstand heavy use and provide a safe environment for children to play. Steel sheets can be used to construct various playground equipment such as slides, climbing structures, and swing sets. Additionally, steel is resistant to weather conditions, making it a suitable choice for outdoor playgrounds. The material can be easily molded and shaped into different designs, allowing for creativity and customization in playground equipment. Overall, steel sheets are a reliable and long-lasting option for playground equipment, ensuring the safety and enjoyment of children.

Send your message to us

Corrugated steel sheets for roofing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords