Typar Continuous Filament Woven Geotextile/Geotextiles

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continuous Filament Woven Geotextile/Geotextiles

Desciriptions:

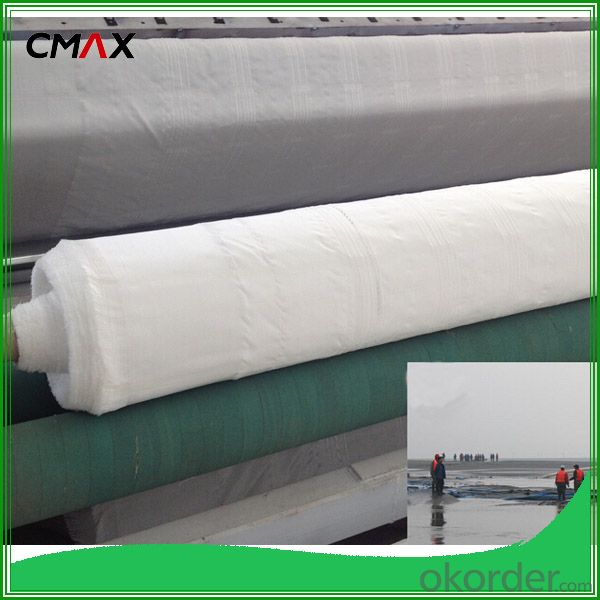

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

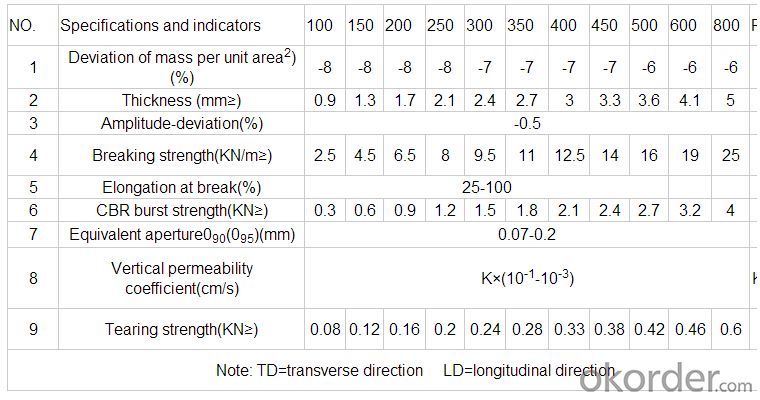

Specifications and Technical datas:

| Weight / Mass | 100gsm - 2000gsm/m2 |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Can geotextiles be used for reinforcement of canal banks?

- Yes, geotextiles can be used for reinforcement of canal banks. Geotextiles are commonly employed in civil engineering projects to enhance the stability and strength of soil and structures. In the case of canal banks, geotextiles can be used to control soil erosion, improve drainage, and provide reinforcement against potential slope failures. They are effective in distributing loads, reducing soil movement, and preventing the loss of fine particles, which ultimately helps in maintaining the integrity and stability of canal banks.

- Q: What are the composite geomembranes suitable for use? What are the characteristics of it? There are several kinds of composite geotextiles?

- Widely used in water conservancy, chemical industry, construction, transportation, subway, tunnel, garbage disposal field and other anti-seepage project, high puncture resistance, large coefficient of anti-aging performance, to adapt to the environmental temperature range Excellent anti-drainage performance Geotextile: A cloth a film two cloth a film a cloth two films more cloth film and so on

- Q: There is no geotextile in the sand filter with the biological retention

- You can use geotextiles

- Q: Can geotextiles be used for erosion control in river levees?

- Yes, geotextiles can be used for erosion control in river levees. They are commonly used as a protective barrier to prevent soil erosion and stabilize the levee slopes. Geotextiles can effectively control erosion by providing reinforcement and filtration, reducing water velocity and sediment movement, and promoting vegetation growth.

- Q: Can geotextiles be used in coastal revetment works?

- Yes, geotextiles can be used in coastal revetment works. Geotextiles are commonly used as a component in coastal revetment systems to provide erosion control and stabilization. They can help to reinforce the soil, prevent erosion, and enhance the stability of the revetment structure.

- Q: Can geotextiles be used in underground storage tank applications?

- Yes, geotextiles can be used in underground storage tank applications. Geotextiles are often employed as a protective barrier or liner to prevent soil erosion, provide filtration, and enhance drainage in various construction projects, including underground storage tanks. They can help in maintaining the structural integrity of the tank by preventing soil migration and reducing the risk of contamination.

- Q: Composite waterproof board, is the waterproof board and geotextile stick together call it?

- Yes. Now there are mainly adhesive technology, thermal composite process, Laminating process.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by providing a barrier that separates soil layers and prevents them from being washed away by water or wind. They stabilize the soil, promote vegetation growth, and enhance drainage, ultimately reducing erosion and maintaining the integrity of the landscape.

- Q: Can geotextiles be used for reinforcement of underground tunnels?

- Yes, geotextiles can be used for reinforcement of underground tunnels. Geotextiles are permeable fabrics that can provide soil stabilization, erosion control, and reinforcement. When used in the construction of tunnels, geotextiles can help to strengthen the surrounding soil, prevent soil erosion, and enhance the overall stability and durability of the tunnel structure.

- Q: How are geotextiles used in sports field construction?

- Geotextiles are used in sports field construction to stabilize the soil, improve drainage, and prevent the migration of soil particles. They are commonly used as a base layer under the turf to enhance the field's durability and longevity. Additionally, geotextiles help to reduce the risk of erosion and maintain the field's evenness, allowing for optimal playing conditions.

Send your message to us

Typar Continuous Filament Woven Geotextile/Geotextiles

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords