Perforated Continuous Casting Aluminum Coil for Prepainted AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

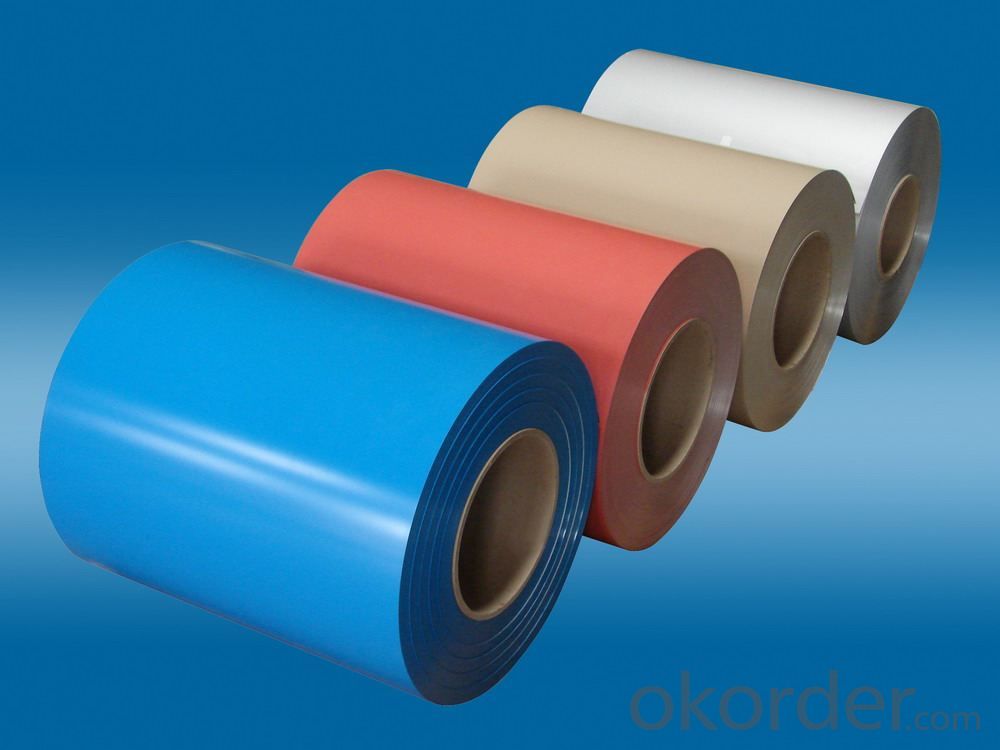

1.Structure of Continuous Casting Aluminium Coil for Prepainted AA3003

Continuous Casting Aluminium Coil for Prepainted AA3003 can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coil for Prepainted AA3003

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 2 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheet be painted?

- Yes, aluminum sheet can be painted. However, it is important to properly prepare the surface before painting to ensure that the paint adheres well and lasts longer. The process usually involves cleaning the aluminum sheet to remove any dirt, grease, or oxidation, followed by applying a primer to promote better adhesion. Once the primer is dry, you can then apply the paint of your choice. It is recommended to use a high-quality paint suitable for metal surfaces to achieve the best results. Additionally, if the aluminum sheet will be exposed to outdoor elements, it is advisable to use a paint that is specifically formulated for exterior use, in order to provide protection against weathering and corrosion.

- Q: What are the different methods of joining aluminum sheets?

- Aluminum sheets can be joined using a variety of methods, each with its own benefits and suitability for specific applications. These methods include: 1. Welding: Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW) are all techniques that can be used to join aluminum sheets. TIG welding is commonly chosen for thin sheets due to its precise control and high-quality results. MIG welding, on the other hand, is faster and more suitable for thicker sheets. RSW creates strong welds in a short amount of time by using localized heat and pressure. 2. Adhesive bonding: Adhesive bonding involves using specially designed adhesives for joining aluminum. This method provides excellent strength, even distribution of stress, and corrosion resistance. It is often utilized in applications where aesthetics and weight reduction are important, such as in the automotive and aerospace industries. 3. Mechanical fastening: Mechanical fastening methods, such as riveting and bolting, can also be used to join aluminum sheets. Riveting involves deforming a rivet that passes through pre-drilled holes, while bolting uses screws or bolts. These methods are suitable for temporary or semi-permanent joints and offer easy disassembly if needed. 4. Friction stir welding: Friction stir welding is an innovative method that utilizes a rotating tool to generate frictional heat between the aluminum sheets. This creates a plasticized region that is stirred together to form a solid-state weld. Friction stir welding is particularly useful for large and complex aluminum structures, providing high strength and integrity. 5. Clinching: Clinching is a cold-forming process that joins aluminum sheets without the need for heat or additional materials. It involves pressing the sheets together, creating a mechanical interlock and a strong joint. This method is cost-effective, efficient, and suitable for joining dissimilar metals. 6. Laser welding: Laser welding involves using a high-energy laser beam to melt and fuse the aluminum sheets together. It offers precise control, minimal heat input, and high welding speeds, making it suitable for thin and delicate sheets. Laser welding also provides excellent aesthetics and minimal distortion. The choice of joining method depends on various factors, such as application requirements, material thickness, cost considerations, and desired joint strength. Each method has its own advantages and limitations, and selecting the most appropriate method is crucial to ensure a successful and durable joint.

- Q: Are aluminum sheets easy to clean and maintain?

- Aluminum sheets prove to be fairly effortless to clean and upkeep. Due to its innate resistance to corrosion and rust, aluminum stands as a material requiring minimal maintenance. When it comes to cleaning aluminum sheets, a gentle soap and water solution, combined with a soft cloth or sponge, will suffice. It is advisable to refrain from utilizing abrasive cleansers or scrub brushes, as they possess the potential to mar the surface. Furthermore, it is imperative to thoroughly dry the aluminum sheets following cleaning in order to prevent the occurrence of water spots or stains. Routine maintenance entails promptly wiping away any spills or stains and periodically administering a protective coating to enhance its durability. All in all, aluminum sheets present themselves as a convenient option for individuals in search of a material that is both easy to clean and maintain.

- Q: What is an aluminum sheet?

- Typically rectangular in shape and with a consistent thickness, an aluminum sheet is a flat piece of aluminum. This lightweight and versatile metal, known for its corrosion resistance and high strength-to-weight ratio, is used to create aluminum sheets. These sheets find common application in industries like construction, transportation, aerospace, and manufacturing. To meet specific requirements, they can be further processed, cut, shaped, or formed. Aluminum sheets offer a wide range of options for different uses, as they come in various grades and finishes, including smooth, brushed, and textured surfaces.

- Q: I use an aluminum chloride deodorant at night for hyperidrosis...I'm scared I may get senile dementia when i get older!!!!! can anyone give advice??? pls..i've been using it for 3yrs

- it extremely is been shown theoretically achieveable for aluminum to reason breast maximum cancers, yet that may no longer probably proper to aluminum chloride hexahydrate, fairly in its customary use. you isn't excessively in probability for breast maximum cancers in case you employ it. i'm assuming you're talking approximately utilising it as in antiperspirant (as very almost all antiperspirants use it). if it extremely is so, the hyperlink I linked will help ease your - and with a bit of luck your mom's - concerns. at the same time because it does word that extra study is mandatory on aluminum absorption interior the breast, there is likewise a learn exhibiting that there substitute into no hyperlink between antiperspirant utilization and breast maximum cancers. Edit: additionally, in connection with the different poster, only because of the fact somebody thinks that something contributed to their condition would not make it a reason (without insult meant in direction of the survivors - i'm happy to pay attention that the poster's acquaintances have survived the terrible sickness). plenty because of the fact the chilly air would not supply you colds as many think of, antiperspirants won't supply you maximum cancers. yet I do accept as true with the different sentiment - in case you're extremely as traumatic as you look related to the drug, you should choose for to attempt an option and notice if it works.

- Q: If Aluminum can, in fact, not be sterilized I would love to know why.

- Aluminum can be sterilized. A variety of methods exist for sterilizing any material, including (but certainly not limited to) food, medical devices such as needles/syringes, and surgical metals. Here are two ways you can sterilize aluminum: Autoclave it. Autoclaving is a process where you heat an item up to approximately 300 degrees F, under high pressure. The combination of the pressure and the heat kills anything that's alive, rendering it sterile. Almost every lab in the country has at least one autoclave machine and most labware manufacturers today build their products keeping in mind that the product will be autoclaved (perhaps many dozens of times) in the future. Gamma radiation. Gamma radiation sources, such as Cobalt-60, are used to sterilize almost every item you can think of that is individually packaged in a hospital or laboratory, including test tubes, general labware, and any other liquid-handling instruments. Some foods are also sterilized this way to increase shelf life (don't worry, the food never holds any of the radiation). Aluminum can not only be sterilized, but it can be sterilized using techniques and protocols very common today. Hope this helps.

- Q: Are aluminum sheets suitable for signage?

- Signage can greatly benefit from the use of aluminum sheets. This material is known for its versatility and numerous advantages when it comes to signage applications. With its lightweight nature, durability, and resistance to corrosion, aluminum is an excellent choice for both indoor and outdoor signage. Regardless of weather conditions, be it rain, snow, or intense UV exposure, aluminum sheets will not deteriorate or fade. Furthermore, aluminum sheets are easy to work with, providing a wide range of customization options such as embossing, engraving, and digital printing. Not only are they cost-effective, but they also have a long lifespan, ensuring that signage remains in top-notch condition for extended periods. Ultimately, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a preferred choice for signage.

- Q: Can aluminum sheets be used for outdoor applications?

- Certainly, outdoor applications can involve the utilization of aluminum sheets. Aluminum, being both resilient and resistant to corrosion, proves itself suitable for a diverse array of outdoor purposes. It is frequently employed in tasks such as roofing, siding, guttering, as well as outdoor signage. A distinguishing feature of aluminum sheets is their exceptional strength-to-weight ratio, rendering them perfect for situations where a material that is simultaneously lightweight and robust is imperative. Moreover, aluminum possesses the inherent ability to generate a safeguarding oxide layer, thereby shielding itself from external elements. Consequently, it emerges as a dependable option for outdoor settings.

- Q: Can aluminum sheets be used for sign making?

- Yes, aluminum sheets can be used for sign making. Aluminum is a commonly used material for making signs due to its durability, lightweight nature, and resistance to rust and corrosion. It is a versatile material that can be easily cut, shaped, and printed on, making it suitable for various sign making applications.

- Q: Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

Send your message to us

Perforated Continuous Casting Aluminum Coil for Prepainted AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords